Level 0, managed by the General Contractor and Owners Commissioning Consultant, serves as the initial stage of the project commissioning process, where the primary focus is on laying the foundation for subsequent steps, evaluating, planning, and documenting the necessary information, tasks, and activities for successful commissioning.

It is important to note that while Level 0 primarily focuses on the below tasks, some will continue throughout the project and carry over into subsequent levels.

The below highlights the tasks and activities that will be completed during Level 0; these are further explained and expanded throughout the article:

- Formation of a Competent and Dedicated Commissioning Team,

- Development of a Comprehensive 100% Design,

- Performing Design Reviews,

- Conducting Thorough Single Point of Failure Reviews,

- Establishment of a Clear Commissioning Process,

- Conducting Productive Meetings and Workshops to Facilitate Collaboration,

- Discussion and Agreement on Commissioning Document Expectations,

- Defining and Agreeing Upon Specific Requirements for Factory Testing,

- Create, Issue, and Approval of Commissioning Documentation.

🚀 If looking at a standard commissioning delivery model based upon ASHRAE, Level 0 would equate to the ‘Pre-Design and Design Stages’.

⬛ Additional Resources

To help navigate around the site and provide additional resources, we’ve added plenty of helpful links throughout this article to help you complete your data center commissioning, also below is a list of other articles that we have written that you may find helpful:

- Data Center Commissioning | What is it? including Guideline

- Data Center | 0, 1, 2, 3, 4, 5, 6 Levels of Commissioning [high-level]

- Data Center Redundancy | N, N+1, N+2, 2N & 2N+1 Explained

- Data Center Tiers | 1, 2, 3 & 4 Explained with Downloads

- Level 1 – Data Center Commissioning | Factory Testing

- Level 2 – Data Center Commissioning | Component Delivery, Installation & Pre-Start Up

- Level 3 – Data Center Commissioning | Systems Start-Up

- Level 4 – Data Center Commissioning | Functional Testing

- Level 5 – Data Center Commissioning | Integrated Testing

- Level 6 – Data Center Commissioning | Closeout & Turnover

🟩 Using the RASCI Matrix

For the roles and responsibilities, we will utilize the RASCI format, which helps with defining and communicating the required roles and responsibilities within the process and will dictate, via a structured framework, who is Responsible, Accountable, Supportive, Consulted, and Informed for each task, activity, or decision.

Using the matrix will enhance management and teamwork, promoting clarity, reducing confusion, and fostering effective communication.

| Responsible | [R] | This is the person that is responsible for doing the work ensuring the activities are completed by the relevant team members, they can also provide comments as well. |

| Approve | [A] | This person comments, approves and signs off and owns the activity. |

| Supportive | [S] | Persons who will provide support to the Responsible party, aiding in completion of the task. |

| Consulted | [C] | Opinion sought, where required. |

| Informed | [I] | This person is informed when a decision is made, or an activity is performed. They may be required to act because of the outcome. |

🟩 Roles of Team Members

The following participants will be involved in the delivery of the Level 0 – Commissioning Tasks and Activities:

| Owner | [O] | The owner is the person who will own/occupy or run the facility once it is complete; they have the final say in the overall expectations of the project and finance it. |

| Building Operator | [BO] | The company and people responsible for operating the facility once handed over. |

| Project Manager | [PM] | The project manager, employed to represent the owner, running and managing the overall project and programme. [where owner is not fully involved in the day to day running of the project]. |

| Commissioning Provider | [CxP] | The consultant employed by the Owner to ensure that the project is verified to meet their expectations, |

| Designer | [DES] | Responsible for taking the Owner's expectations/requirements and creating a design that works in line with them, |

| General Contractor | [GC] | The company employed to construct, build and commission the project, |

| Sub-Contractor | [SC] | Works for the General Contractor delivering specialist services |

| Vendor/Supplier | [VEN] | Supplies goods, materials and equipment for the project. |

🟩 Level 0 – Tasks, Activities, Roles, and Responsibilities

🟧 Level 0 – 65 Step Matrix

The below table has been written to allow planning of Level 0 tasks and activities, and we have included a purchasable resource that can be downloaded at the end of this article.

| Level | Task/Activity | O / PM | BO | CxP | Des | GC | Ven |

|---|---|---|---|---|---|---|---|

| L0-01 | Write and Issue Owners Project Requirements [OPR] Document. | A | C | R | S | I | I |

| L0-02 | Oversee Owners Project Requirements [OPR] are being met throughout the contract design stage, and issue updates to the project team. | A | C | R | S | I | I |

| L0-03 | Write and Issue Basis of Design [BOD] Document. | A | I | I | R | I | I |

| L0-04 | Ensure that the Basis of Design [BOD] is updated and reviewed by Main Contractor during the 100% design stage, and issue to the project team. | A | I | I | R | I | I |

| L0-05 | Develop design [30%, 60%, 90%, 100%] and issue documentation for review and approval. | A | I | I | R | I | I |

| L0-06 | Create, Develop, and Issue Computational Fluid Dynamics Study [CFD] Document. | A | I | I | R | I | I |

| L0-07 | Complete Commissioning Review of Design [60% to 100%] and Issue Report. | A | I | R | S | I | I |

| L0-08 | Conduct Short Circuit / Single Point of Failure Coordination Study | A | I | R | S | I | I |

| L0-09 | Issue Commissioning Document List covering all stages until handover. | A | I | R | S | I | I |

| L0-10 | Write and Issue Data Centre Commissioning Guideline Document. | A | I | R | S | I | I |

| L0-11 | Agree on Sequencing and Duration of Level 4 & 5 Requirements. | A | I | R | I | S | I |

| L0-12 | Issue Initial Integrated and Sequenced Commissioning Programme. | A | I | R | I | S | I |

| L0-13 | Issue Commissioning Process Flow Diagram covering all stages until handover. | A | I | R | I | I | I |

| L0-14 | Agree Commissioning Process and Responsibility Matrix. | I | I | A | I | R | I |

| L0-15 | Issue Commissioning Team Organigram covering this stage. | A | S | R | S | S | I |

| L0-16 | Agree equipment to be Factory Tested. | A | I | R | S | I | I |

| L0-17 | Create, Develop, and Issue Load Bank & Metering Plan for Level 4 & 5 works. | A | I | R | S | I | I |

| L0-18 | Write and Issue Initial Commissioning Plan. | A | I | R | S | I | I |

| L0-19 | Write and Issue Construction Commissioning Specification. | A | C | R | S | I | I |

| L0-20 | Upon contract award, 'Form Commissioning Team' and issue organigram. | I | C | A | I | R | S |

| L0-21 | Set up Cx Electronic Platform [Levels 1-6] for later input of commissioning checklists, test procedures and observations/issues. | A | C | R | S | S | S |

| L0-22 | Set up and discuss use Document Management System and Numbering Structures for the testing and commissioning works. | A | C | R | S | S | S |

| L0-23 | Conduct Commissioning Kick Off meeting. | I | I | A | I | R | S |

| L0-24 | Create, Develop, and Issue Commissioning Communication Protocol. | I | I | A | I | R | S |

| L0-25 | Create, Develop, and Issue Material Submission Document List. | I | I | I | A | R | S |

| L0-26 | Issue Integrated and Sequenced Commissioning Programme. | I | I | A | I | R | S |

| L0-27 | Issue Integrated and Sequenced Commissioning Work Logics. | I | I | A | I | R | S |

| L0-28 | Agree on method for Capturing Site Issues and Observations. | I | I | A | I | R | S |

| L0-29 | Agree on Tagging Process and design of tags to be used. | I | I | A | I | R | I |

| L0-30 | Agree on format and content of Factory Testing Scripts. | I | I | A | I | R | S |

| L0-31 | Agree on format and content of Factory Testing Reports. | I | I | A | I | R | S |

| L0-32 | Plan / programme Factory Testing. | I | I | A | I | R | S |

| L0-33 | Agree on format and content of Confirmation to Ship Certificates. | I | I | A | I | R | S |

| L0-34 | Agree Training Requirements and Write Training Manual. | I | S | A | I | R | S |

| L0-35 | Develop Training Programme. | I | S | A | I | R | S |

| L0-36 | Agree on format and content of Pre-Start Up Checklists. | I | I | A | I | R | S |

| L0-37 | Agree on format and content of Functional Testing Procedures. | I | I | A | I | R | S |

| L0-38 | Agree on format, content, and process for Inviting Owner Team for Witnessing and Verification. | I | I | A | I | R | S |

| L0-39 | Agree Final Testing Pack information to be included in O&M. | I | I | A | I | R | S |

| L0-40 | Agree on format and content of Daily, Weekly, Monthly Commissioning Reports. | I | I | A | I | R | S |

| L0-41 | Agree on format and content of 2 Week Look Ahead Schedule. | I | I | A | I | R | S |

| L0-42 | Agree on format and content of Final Commissioning Report. | A | I | R | I | S | I |

| L0-43 | Agree on format and content of Systems Manual. | A | C | R | I | S | I |

| L0-44 | Agree O&M Requirements. | I | C | A | I | R | S |

| L0-45 | Write and Issue Final Commissioning Plan. | I | I | A | I | R | S |

| L0-46 | Conduct Commissioning Focused Meetings and Workshops, issuing Minutes. | I | I | A | S | R | S |

| L0-47 | Provide to CxP, Commissioning Focused Reports [monthly/weekly]. | I | I | A | I | R | S |

| L0-48 | Provide to Owner, Commissioning Focused Reports [monthly/weekly]. | A | I | R | S | S | S |

| L0-49 | Review Information for Gap Analysis between Owner Specified Equipment and Main Contractor works. | A | I | R | S | S | S |

| L0-50 | Create, Develop, and Issue Electrical Discrimination Study. | I | I | A | S | R | S |

| L0-51 | Create, Develop, and Issue Arc Flash Study. | I | I | A | S | R | S |

| L0-52 | Agree on Arc Flash Sticker Template to be used. | I | I | A | I | R | I |

| L0-53 | Agree Thermal Graphic Inspection locations. | I | I | A | S | R | S |

| L0-54 | Create, Develop, and Issue Thermal Graphic Procedure and Plan. | I | I | A | S | R | S |

| L0-55 | Create, Develop, and Issue Electrical Lock Out, Tag Out Process and Procedure. | I | I | A | S | R | S |

| L0-56 | Create, Develop, and Issue Plant Settings Report. | I | I | A | I | R | I |

| L0-57 | Create, Develop, and Issue Schedule of required Work Permits for commissioning activities. | I | C | A | I | R | I |

| L0-58 | Create, Develop, and Issue Commissioning Strategies. | I | I | A | S | R | S |

| L0-59 | Agree Sequence of Operation [SOO] List. | I | I | A | I | R | S |

| L0-60 | Create, Develop, and Issue Sequence of Operations [SOO]. | I | I | A | S | R | S |

| L0-61 | Create, Develop, and Issue BMS Graphic Document. | I | I | A | S | R | S |

| L0-62 | Create, Develop, and Issue BMS Points List Document. | I | I | A | S | R | S |

| L0-63 | Create, Develop, and Issue Fire Cause & Effect Matrix. | I | I | I | A | R | S |

| L0-64 | Provide to Owner, Level Close Out Reports. | I | I | A | I | R | S |

| L0-65 | Sign off Level. | A | I | R | S | S | S |

🚀 Below is an overview of each step noted in the above table.

🟧 L0-01 Write and Issue Owners Project Requirements [OPR]

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

An Owner’s Project Requirement (OPR) document is a comprehensive and structured document that outlines the expectations, goals, and specific requirements set by the owner or client for a construction project. It is a foundational guide that helps align the project team’s efforts and decisions with the owner’s vision and objectives.

The commissioning provider will manage and create this document with support from the Owner.

It will be the reference document for the Designers ‘Basis of Design Document’.

🟧 L0-02 Delivering Owners Project Requirements

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

Through intermittent reviews, the commissioning provider ensures that the Owner’s Project Requirements [OPR] are met throughout the design stage, issuing any updates to the project team if the document is modified.

🟧 L0-03 Write and Issue Basis of Design Document [BoD]

Owner: Approve | Building Operator: Informed | Commissioning Provider: Informed | Designer: Responsible | General Contractor: Informed | Vendor: Informed

A Basis of Design [BoD] document is a structured and comprehensive document in construction projects that outlines the fundamental principles, criteria, and reasoning behind the design choices and specifications for its various systems and equipment. It is a foundational reference that helps guide the project team, including architects, engineers, contractors, and stakeholders, in making informed decisions and ensuring consistency throughout the design and construction phases.

The Designer will manage, create and issue this document.

It will be the reference document for the overall design of the facility.

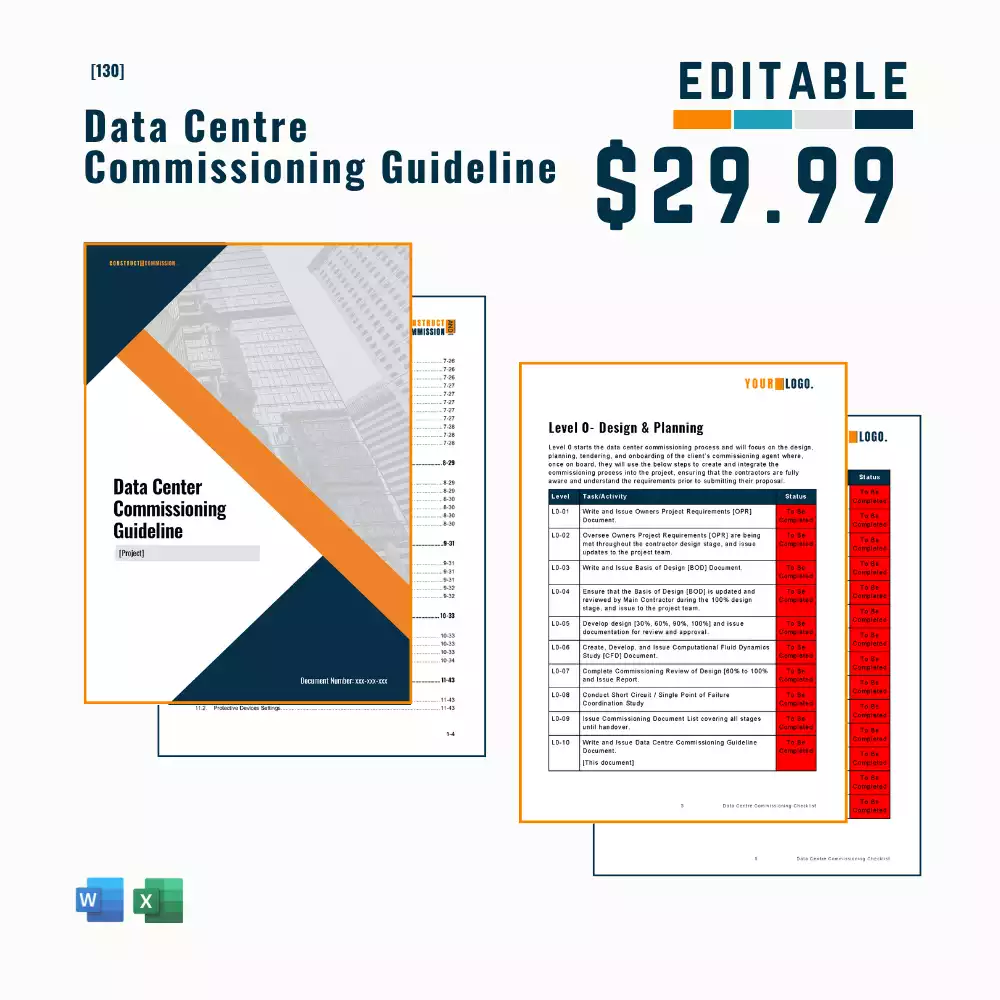

- Use Straight Away

- Insert in Tender Documents

- Industry Wide Process from Level 0 to Level 6

- Detailed Responsibility and Roles

- Includes Commissioning Checklist

Aimed at anyone who needs a detailed delivery plan and checklist for deploying Commissioning within a Data Center Project, this document is formatted in Microsoft Word/Excel and written so that it can be deployed quickly and easily with minimal updating to suit your specific needs.

[Once through to the shop there is a sample of the document to view]

- Easy

- Quick

- High Level

- Tracker

Here is our open copy [MS Word] & [MS Excel] of the Data Center Commissioning Checklist, for making life a little easier...

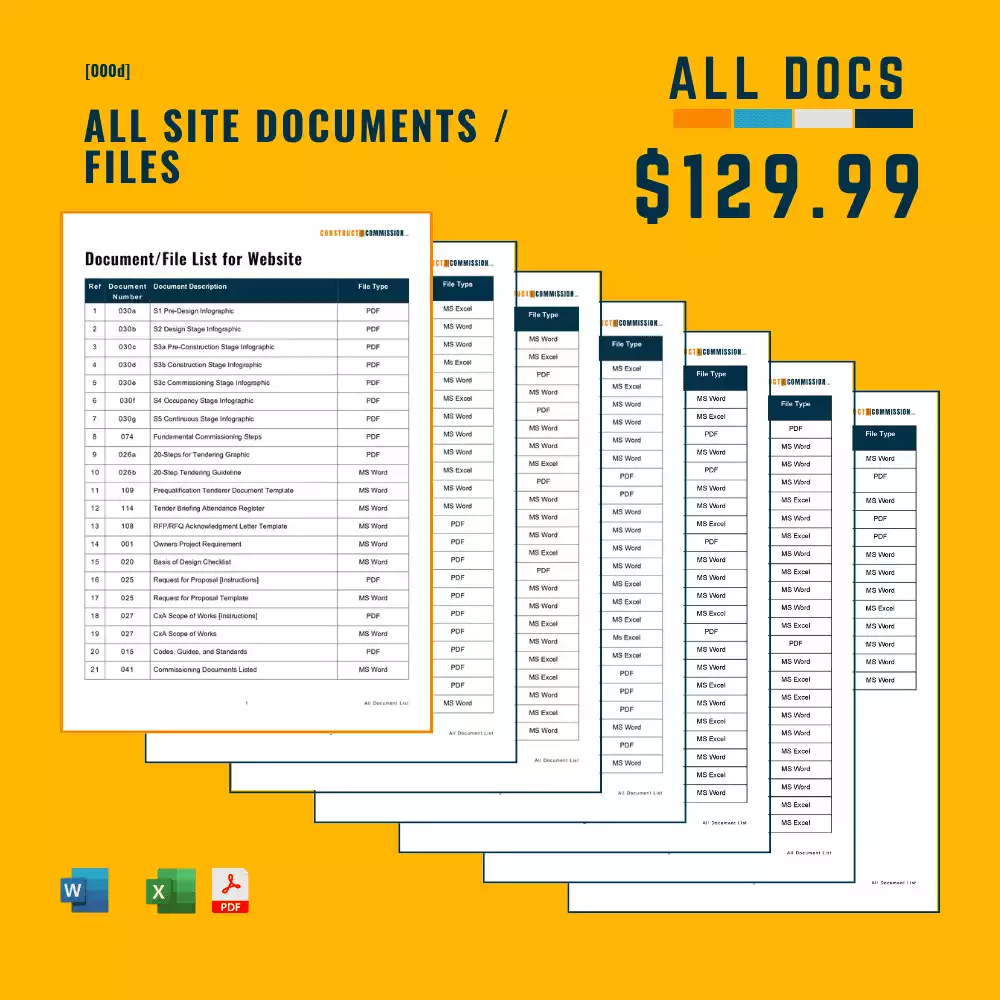

- 126No. Documents

- Use Straight Away

- Amazing Value

We have been asked several times to create a complete document package covering everything we have uploaded to the site.

So it's taken some time, but here it is....126No. Documents for you to download in Microsoft Word, Microsoft Excel & PDF Formats.

CLICK THE BUY HERE TO SEE/DOWNLOAD A FULL LIST OF DOCUMENTS INCLUDED...

🟧 L0-04 Delivering Basis of Design Document [BoD]

Owner: Approve | Building Operator: Informed | Commissioning Provider: Informed | Designer: Responsible | General Contractor: Informed | Vendor: Informed

Through intermittent reviews, the designer ensures that the Basis of Design Document [BoD] is updated, where required, and reviewed during the 100% design stage, issuing any modifications to the project team.

🟧 L0-05 Develop the Design, 30%, 60%, 90% & 100%

Owner: Approve | Building Operator: Informed | Commissioning Provider: Informed | Designer: Responsible | General Contractor: Informed | Vendor: Informed

The terms “30%, 60%, 90%, and 100% design” refer to different stages of design development within the project. These stages represent the progression of a design from its initial concept to a fully detailed and finalized plan, with the percentages indicating the level of completion and detail achieved at each stage.

The designer shall develop each stage before issuing it to the project team for review and approval.

🟧 L0-06 Conduct Computational Fluid Dynamics [CFD] Study

Owner: Approve | Building Operator: Informed | Commissioning Provider: Informed | Designer: Responsible | General Contractor: Informed | Vendor: Informed

A Computational Fluid Dynamics Study (CFD) employs computer simulations to analyze air flow and heat transfer within a data center’s environment, helping to optimize cooling efficiency, identify hotspots, and enhance thermal management.

🟧 L0-07 Conduct Commissioning Reviews [60% & 100%]

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

The CxP shall conduct a Commissioning Review of the Design at 60% and 100% assessing the project’s design detail to ensure it aligns with project goals, codes, and local/regional standards.

Once complete, they will issue a report communicating findings, ensuring design quality, addressing deviations, and enhancing construction readiness for a reliable and efficient data center.

🟧 L0-08 Short Circuit / Point of Failure Study

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

The CxP will conduct a Short Circuit / Single Point of Failure Coordination Study to assess and analyze the electrical systems identifying any vulnerabilities, like short circuits or single points of failure, ensuring that the electrical systems’ protective devices work correctly and minimize downtime risks, enhancing data center reliability, safety, and operational continuity.

🟧 L0-09 Provide Documentation List

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

A comprehensive list outlining all required commissioning project documentation, including specifications, plans, manuals, pre-functional checklists, functional testing, integrated systems testing, test records, reports, trackers, and closeout information, will be provided by the Commissioning Provider.

This ensures a clear understanding of the expectations across the whole project from the outset.

🟧 L0-10 Provide Data Center Guideline Line Document

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Informed | Vendor: Informed

The Commissioning Guideline Document / Specification for the project will be written and issued by the CxP. This document details the step-by-step commissioning process, encompassing testing, verification, roles/responsibilities, and performance benchmarks, ensuring a clear and consistent quality and adherence to the project requirements.

🟧 L0-11 Agree on Level 4 & 5 Works

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Informed

The CxP should establish and agree upon the sequencing and duration of Level 4 & Level 5 works, enabling the General Contractor to understand the project timeline and align construction activities, resulting in a coherent and well-coordinated program.

🟧 L0-12 Provide Initial Sequenced Commissioning Programme

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Informed

The initial commissioning program serves as a roadmap to help the overall project understand the initial sequencing and time for the project’s commissioning activities. This information can then be integrated into the initial construction programme for planning.

🟧 L0-13 Provide Commissioning Process Flow

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Informed | Vendor: Informed

The Commissioning Process Flow is created to identify the necessary steps to complete the overall commissioning tasks and activities.

🟧 L0-14 Agree on Commissioning Process

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Informed

Hold a workshop with the commissioning team members to review and agree on the overall commissioning process for the project, update the information in step 13 where required.

🟧 L0-15 Provide Initial Commissioning Team Org Chart

Owner: Approve | Building Operator: Support | Commissioning Provider: Responsible | Designer: Supported | General Contractor: Supported | Vendor: Informed

The initial Commissioning Team Organigram provides a visual representation that clarifies team roles, responsibilities, and reporting hierarchy, enhancing coordination, minimizing ambiguities, helping to foster effective communication among stakeholders, and streamlining the commissioning process.

🟧 L0-16 Factory Testing Agreement

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Supported | General Contractor: Informed | Vendor: Informed

Agree on the type, model numbers, and quantity of equipment to be factory tested with the owner. This information can then be included within the commissioning guideline/specification document.

🟧 L0-17 Issue Load Bank & Metering Plan

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Supported | General Contractor: Informed | Vendor: Informed

A Load Bank & Metering Plan for Level 4 & 5 testing should outline the equipment needed, locations, and the methodology for applying artificial loads to the systems that will allow load testing to commence.

🟧 L0-18 Issue Initial Commissioning Plan

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Supported | General Contractor: Informed | Vendor: Informed

An initial commissioning plan outlines the strategy for the systematic commissioning activities on the project, defining roles, phases, activities, and timelines, ensuring thorough testing, verification, and integration of systems for optimal performance and compliance while coordinating with stakeholders and managing risks.

🟧 L0-19 Create the Construction Commissioning Specification

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Supported | General Contractor: Informed | Vendor: Informed

The Commissioning Provider should write the specification outlining the specific requirements for all commissioning activities for the functional testing and general commissioning works.

🚀 If able to, it can be combined with the Commissioning Guideline Document.

🟧 L0-20 Form the Commissioning Team and Org Chart

Owner: Informed | Building Operator: Consulted | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Upon contract award, the General Contractor should form their Commissioning Team and, once approved, update the previous organigram that was issued. This will ensure the integration of the complete team covering the Owner, Building Operator, Commissioning Provider, Designer, General Contractor, and Vendor, allowing a visual representation of team roles and responsibilities throughout the overall process.

🟧 L0-21 Set up the Cx Electronic Platform

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

The commissioning provider establishes the Commissioning Electronic Platform for Levels 1-6; this platform is used to help trace, track, and document the commissioning checklists, test procedures, and observations/issues ensuring that the collection of data is streamlined, stored in a centralized location, enhance transparency/traceability, and support efficient project team collaboration.

🟧 L0-22 Set up the Document Management System

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

The CxP shall oversee the commissioning element of the overall project document management system, they shall ensure that the commissioning team is trained and able to use the system.

🟧 L0-23 Commissioning Kick-Off Meeting

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A commissioning kick-off meeting will be conducted by the General Contractor, where they present the project’s commissioning process, objectives, scope, roles/responsibilities, and expectations.

🟧 L0-24 Develop Communication Protocol

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The communication protocol outlines structured guidelines for effective information exchange among the commissioning team for the tasks and activities needed to complete the work.

It should define communication channels, formats, frequency, and responsibilities.

🟧 L0-25 Develop Material Submission Schedule

Owner: Informed | Building Operator: Informed | Commissioning Provider: Informed | Designer: Approve | General Contractor: Responsible | Vendor: Support

The General Contractor should issue a material submission schedule that provides information and deadlines for submitting construction materials’ details for approval. This will ensure timely issues and reviews, allowing for better-planned procurement and quality control.

🟧 L0-26 Provide Integrated and Sequenced Commissioning Programme

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A fully integrated and sequenced commissioning programme should be written and issued by the General Contractor that covers all aspects of the tasks and activities needed to complete the project promptly.

🟧 L0-27 Provide Integrated and Sequenced Logics

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A graphical representation outlining the sequence of commissioning activities and their dependencies can be used instead of a fully sequenced programme. The logic can help to visually depict the project schedule’s critical path, highlighting milestones and deadlines.

🟧 L0-28 Agree On Capturing Site Issues and Observations

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Agreeing on capturing and managing the Site Issues and Observations from the outset will allow the project to understand the process, enhancing project efficiency, reducing disputes, and helping ensure a smooth process.

🟧 L0-29 Agree On Tagging Process

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

‘Tagging’ in data center commissioning assigns color-coded labels [Red, Yellow, Green, Blue, and White] to systems and components after each different level 1, 2, 3, 4 & 5, aiding in the tracking and coordination of the tasks and activities.

🟧 L0-30 Agree Factory Testing Script Format

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Factory testing involves evaluating equipment and systems at the manufacturer’s facility [off-site] to ensure they meet performance standards before installation. Agreeing on the Factory Testing Script Format will establish a standardized template for these testing procedures, ensuring clarity, consistency, and understanding among all stakeholders and facilitating accurate execution and comprehensive reporting during factory testing.

🟧 L0-31 Agree on Factory Testing Report Format

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A factory testing report documents the result of the equipment testing conducted off-site at the manufacturer’s facility. It outlines the testing performed, outcomes, and any observations or deviations.

Agreeing on the Factory Testing Report Format early in the process will help establish a standardized approach and speed up the overall review and approval process.

🟧 L0-32 Plan Factory Testing

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Planning factory testing well in advance is essential due to long lead times for ordering equipment and potential distant manufacturing locations, this will help with the delivey of the Level 1 Factory Testing Works.

This early planning aids project expectations and timelines, enabling proactive procurement of materials, arranging logistics, and allocating necessary resources, allowing the team to address thier own individual travel needs.

🟧 L0-33 Confirmation to Ship Certificates/Red Tag

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

‘Confirmation to ship certificates’ or ‘Red Tags’ are documents verifying that equipment has passed factory testing and is ready for shipment to the construction site. This helps ensure traceability and enables easy identification of tested and approved components, streamlining quality control, reducing errors, and ensuring that equipment arrives at the site in compliance with project specifications and standards.

🟧 L0-34 Agree on Training Requirements

Owner: Informed | Building Operator: Support | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Training is crucial for a successful handover as it equips the building operator with the expertise and knowledge to manage and maintain the facilities’ complex systems; defining expectations early will help ensure that the requirements are integrated into the project from the outset.

‘Training requirements‘ should outline the knowledge and skills needed for effective data center operation and how this will be transferred to the operations team.

🟧 L0-35 Develop Training Programme

Owner: Informed | Building Operator: Support | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A training program outlines the structure and content of educational and knowledge transfer sessions for equipping a building operator and their team with the skills to manage a facility effectively.

Completing this early in the process ensures that the project is aware of the expectations and allows deployment time in the overall project programme.

🟧 L0-36 Agree on Pre-Start Up Checklist Format

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Pre-Start Up checks are comprehensive inspections/assessments that are conducted before functional testing of the equipment and systems, ensuring that the items being inspected meet the project requirements and ensure proper installation, configuration, and readiness.

By confirming prerequisites are met and addressing potential issues, we can minimize risks, optimize testing efficiency, and enhance the reliability of subsequent functional tests.

Agreeing on the Pre-Start Up Checklist Format early in the process will help establish a standardized approach and speed up the overall review and approval process.

🟧 L0-37 Agree on Functional Testing Procedure Format

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Conducted after the Pre-Start Up works, functional testing confirms the functionality, efficiency, and interoperability of systems, identifying any discrepancies or issues before the facility’s actual operation. This meticulous testing phase mitigates risks, ensures system reliability, and paves the way for a seamless and successful operational phase.

Agreeing on the Functional Testing Procedure Format early in the process will help establish a standardized approach and speed up the overall review and approval process.

🟧 L0-38 Agree Process for Inviting Owner to Testing

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

It is imperative to establish a structured process for inviting the owner and their team to witness and validate pre-start-up and functional testing. Developing this process early in the project ensures alignment, agreement, and active participation from all stakeholders.

🟧 L0-39 Agree on Final Testing Documentation

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

‘Final testing documentation’ encompasses all crucial information compiled that supports the overall on-site testing records and will contain a range of items, including testing data, procedures with official approval, annotated drawings, calibration certificates, and other details.

Agreeing on a format will allow for a well-organized standardized repository, quality control, aid with review/approval, and expedite data retrieval for any future reference needs.

🟧 L0-40 Agree on Report Formats

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Reporting is a vital component due to its role in providing updates, tracking progress, and identifying issues.

There should be some agreement on the formats and information that should be included as a minimum.

🟧 L0-41 Agree on 2-Week Look Ahead Format

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

A 2-week look ahead schedule focuses on and outlines the upcoming commissioning activities and tasks to be conducted, usually during the Level 2, 3, 4 & 5 testing.

It provides a short-term projection of activities, aiding in planning, resource allocation, and coordination for the whole team.

An agreement should be sought on the content of the 2-week look ahead schedule to ensure everyone agrees on how and when it is issued.

🟧 L0-42 Agree on Final Cx Report Format

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Informed

A ‘final commissioning report‘ is a comprehensive document summarizing a project’s entire commissioning process and delivery. It details testing outcomes, system performance, and compliance with standards. It serves as a past and future record for the owner, project, and building operator.

The format should be agreed with the Owner to ensure all expectations are met.

🟧 L0-43 Agree on Systems Manual Format

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Informed

The main aim of a Systems Manual is to serve as a technical operations manual customized for the facility. Its purpose is to provide a centralized location for information and documentation that offers guidance and instructions on managing and operating the facility’s building systems effectively.

The format should be agreed with the Owner and Operator to ensure all expectations are met.

🟧 L0-44 Agree on O&M Requirements

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Informed

The primary purpose of the Operations and Maintenance (O&M) Manual is to furnish the facilities manager, owner, operator, users, and occupants with a comprehensive and trustworthy document that covers all aspects related to the facility’s management, operation, and maintenance throughout its entire lifespan.

It is one of the most valuable resources at handover with its requirements being discussed and agreed upon early in the project so all team members understand the requirements.

🟧 L0-45 Write and Issue Final Commissioning Plan

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Informed

Once the 100% design has been confirmed and all agreements made around the overall commissioning process, the General Contractor should write and issue the ‘Final Commissioning Plan‘, utilizing the ‘Initial Plan’ as a base.

🟧 L0-46 Conduct Commissioning Meetings & Workshops

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

Commissioning meetings and workshops are conducted during the project to ensure alignment and coordination among the commissioning team.

They help facilitate discussions around the commissioning processes, documentation, schedules, observations, factory and site testing, integrated systems testing, training, manuals, and handover procedures, enhancing understanding, decision-making, and timely resolution of issues, ensuring a well-coordinated, efficient commissioning process that meets project goals and operational requirements.

🟧 L0-47 Issue CxP Commissioning Reports

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

In line with the formats agreed upon in the previous steps, the General Contractor should issue all reports to the Owners Commissioning Provider in line with the expectations. For example, only a Weekly/Monthly would be provided at this early stage, ramping up to the Daily later in the process when site activities are more intense and ongoing.

🟧 L0-48 Issue Owner Commissioning Reports

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

Once received from the General Contractor in the previous step, the Commissioning Provider should issue the Owner a consolidation of the General Contractors’ report and theirs.

🟧 L0-49 Information Gap Analysis

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

A gap analysis should identify any discrepancies of scope between the General Contractor and Owner Specified Equipment, ensuring there are no holes that may impact the installation and commissioning process.

🟧 L0-50 Issue Electrical Discrimination Study

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

An electrical discrimination study analyzes electrical systems, confirming correct sizing and setting of protective devices to prevent faults, tripping, and disruptions. The General Contractor, with a qualified consultant and specialized software, conducts the study, and the Owners Commissioning Manager and Designer review and approve the study results, ensuring that settings meet the expectations.

🟧 L0-51 Issue Arc Flash Study

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

An arc flash study analyzes electrical systems for potential arc flash risks—sudden energy release due to faults. It assesses incident energy levels and protective measures effectiveness. The General Contractor, with a qualified consultant and specialized software, conducts the study, and the Owners Commissioning Manager and Designer review and approve the study results.

🟧 L0-52 Agree on Arc Flash Sticker Template

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Informed

Before energizing the installed equipment, it’s essential to install signage to caution workers about potential electric arc flash dangers. These labels should adhere to the specifications outlined in NFPA 70e.

🟧 L0-53 Agree on Thermal Graphic Inspection Locations

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

Thermographic or infrared testing is a non-contact method used to assess the temperature distribution within an electrical system or its components.

By capturing infrared radiation emitted by components, anomalies such as overheating caused by loose connections or faulty parts can be identified. This helps prevent potential failures and hazards, ensuring the system’s reliability and safety.

The locations where the assessments will be made should be agreed upon between the General Contractor and the Owners Commissioning Provider.

🟧 L0-54 Issue Thermal Graphic Inspection Procedure

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

Once the locations have been agreed upon, the General Contractor should issue a document detailing how the testing will be completed and reported.

🟧 L0-55 Issue Electrical Lock Out/Tag Out Procedure

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

An Electrical Lock Out / Tag Out Procedure is a document that details a systematic process to be employed on a project when powering up and powering down electrical systems to ensure the safety of personnel working on or around the energized or de-energized equipment.

🟧 L0-56 Issue Plant Settings Report

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The “plant settings document” should be provided to ensure a comprehensive document outlining the specific settings, configurations, and parameters for various equipment and systems within each systems infrastructure is written, usually aimed at the Mechanical and Electrical Systems.

This document will then ensure all systems and equipment are setup and operating inline with it.

🟧 L0-57 Issue Schedule of Work Permits

Owner: Informed | Building Operator: Consulted | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Informed

Creating a ‘work permit’ schedule at the beginning of a project allows for proactive planning and coordination of tasks that could impact existing critical operations and the construction/commissioning programme.

Outlining the expectations, and proposed timeline, then seeking approval will help establish a clear understanding of what, when, and how work will be able to commence.

🟧 L0-58 Issue Commissioning Strategies

Owner: Informed | Building Operator: Consulted | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

Created and issued by the General Contractor, commissioning strategies should be written and issued detailing how specific tasks and activities that require more thought than other tests will be completed. For example, how will the systems be powered up with power being distributed around the project to areas needed, or how will an existing systems be integrated into new systems.

🟧 L0-59 Agree Sequence of Operation Schedule

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should issue a list of Control Logic/Sequence of Operations to allow the commissioning team to understand what will be produced, when they will be produced, and to track progress.

🟧 L0-60 Issue Sequence of Operations

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

Once the logic schedule has been issued, the works should commence on creating the documents for review and approval by the Owners Team.

Each logic should clearly show how each system functions and responds to various conditions ensuring they meet the design expectations.

🟧 L0-61 Issue BMS Graphic Document

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

The BMS Graphic Document should provide all information needed for the project team to understand how the graphics will look and what information will be displayed on the BMS screens around the building to allow the operators to monitor, control, and manage the systems.

🟧 L0-62 Issue BMS Points List

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

A ‘BMS Points List’ should be issued by the General Contractor for approval, showing all monitoring and control points so that they are agreed upon and clear on what data will be monitored and controlled for each individual system and component.

The points will also integrate with the BMS Graphic Document above.

🟧 L0-63 Issue Fire Cause & Effect Matrix

Owner: Informed | Building Operator: Informed | Commissioning Provider: Informed | Designer: Approve | General Contractor: Responsible | Vendor: Support

The ‘fire cause and effect matrix’ will be a systematic document that outlines the relationships between potential fire-related events (causes) and the corresponding responses or actions (effects), that are triggered in response to those events.

Using a matrix will help ensure that fire safety systems operate correctly, efficiently, and in a coordinated manner during emergency situations.

🟧 L0-64 Provide Closeout Report

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should issue a comprehensive ‘close-out report’ as a final summary of the level 0 commissioning process, capturing the results, findings, and outcomes of the various steps.

This report should be provided to the Owners Commissioning Provider for review and acceptance.

🟧 L0-65 Sign-Off Level

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

Once the ‘Closeout Report’ has been received, reviewed, and approved by the Owner CxP, the Level 0 works will be deemed complete and a Certificate Issued.

🟩 Level 1 Tasks and Activities

Click on the above for Level 1 – Factory Witness Testing Tasks and Activities

⬜ Level 0 to Level 6 Data Center Commissioning Checklist Template [Open / PDF]

To help us expand the site and create more resources, we created the documentation below in [Microsoft Word] & [Microsoft Excel] for download.

Click the ‘Buy It Now‘ button to purchase the fully editable copy of the document below, which can be used immediately.

You will direct to our shop page.

⬛ Related Articles

INSTALLATION vs. COMMISSIONING | A Quick Explanation…

BUILDING SYSTEMS MANUAL | How to Write One with Roles

HOW TO WRITE | A Method Statement with download

RFP / RFQ TENDERING PROCESS | How to Complete in 20 Steps

4 DIFFERENT TYPES | of Building Commissioning

ASHRAE | Guideline 0 – Is it worth $100…

![Data Center Commissioning Checklist [MS Word] & [MS Excel]](https://constructandcommission.com/wp-content/uploads/2023/07/066-Data-Center-Commissioning-Checklist-Shop.webp)