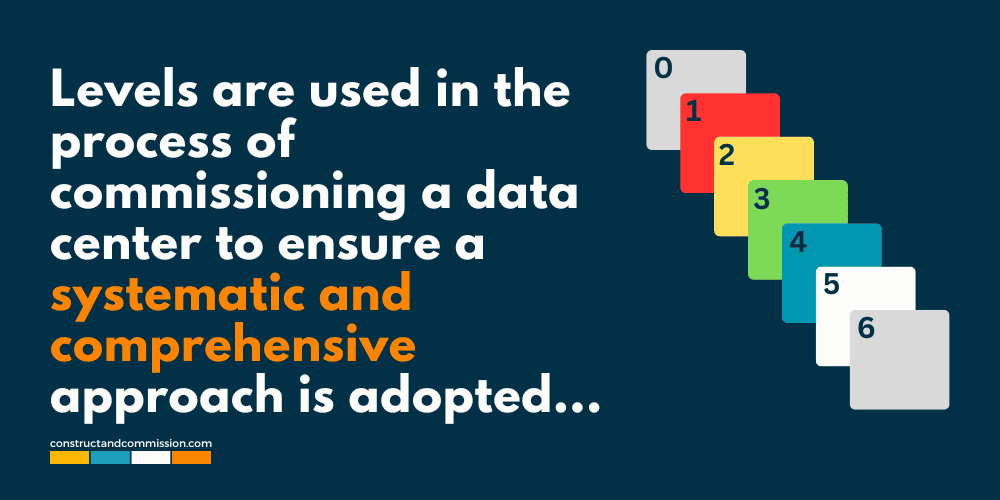

Levels of commissioning are used in the process of commissioning a data center to ensure a systematic and comprehensive approach to testing, verification, and documentation, with each level serving a specific purpose:

- ⬛ LEVEL 0 | Design and Planning,

- 🟥 LEVEL 1 | Factory Testing,

- 🟨 LEVEL 2 | Component Delivery, Installation & Pre-Start-up,

- 🟩 LEVEL 3 | System Start-up,

- 🟦 LEVEL 4 | Functional Testing,

- ⬜ LEVEL 5 | Integrated System Testing,

- ⬛ LEVEL 6 | Closeout / Turnover / Handover

By following these data center levels, the commissioning manager, owner, and facility engineers can ensure that all systems are thoroughly tested, meet required OPR/standards, are fully documented, and are ready for efficient and reliable operation.

🔗 Please note this article is not about Uptime Data Center Tiers, for that please refer to 'DATA CENTER TIERS | Uptime – 1, 2, 3 & 4 Explained'

🟩 Why use Commissioning Levels?

Utilizing the levels allows the project to focus on the commissioning and control the outcome, maintaining the quality assurance that the client usually requires.

Using the levels as a base, a complete process and structure can be developed via flow diagrams, responsibility matrices, and programs, each stage as a ‘gate’ that needs to be completed before moving on to the next stage.

🟩 Can a Data Centre be Commissioned not using the Levels?

Yes, using the levels will not guarantee that the project will be commissioned correctly; a data center can achieve the same outcome of commissioning if a ‘general’ commissioning process is implemented that would be used on an Office-type building.

The levels do not guarantee a quality-orientated process; they provide the base to work from and lay down the expectations for the project to start from.

If we think about it, when we commission a Chiller control system in an office vs. a data center, we would usually complete similar testing [maybe minus the part-load testing in the office due to site constraints].

🟩 Are the 5 Levels the same as the ASHRAE Cx Process?

Although the process is similar, they are also different. Generally, the ASHRAE process [Guideline 0] focuses on documentation having a self-explanatory process and goals, ensuring that the commissioning process is conducted and ongoing commissioning throughout the building life cycle is maintained.

The Data Center Levels 1 to 5 or 0 to 6 are more focused on a ‘commissioning sequence’ focused on the systems and equipment; across multiple data center providers there, we have yet to see an Owners Project Requirements Document, Basis of Design or Systems Manual, for example. Documentation can sometimes feel a second thought.

The best solution is to merge the 2 to get a global delivery taking the best bits of both, which we have done in our checklists and steps as detailed below and in our other articles.

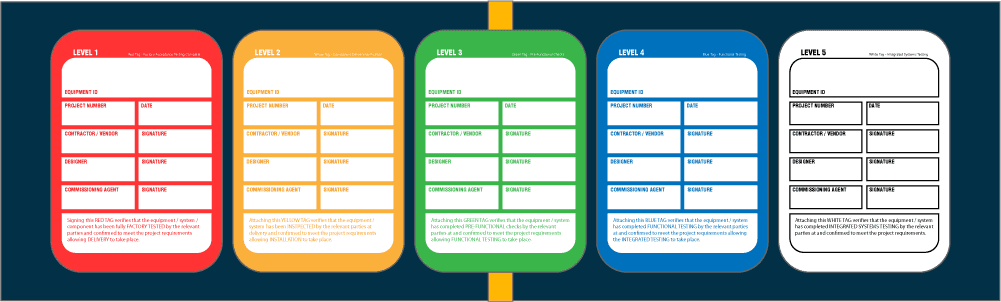

🟩 Commissioning Tags and Colours

Colored tags are installed to visually indicate components and a system’s commissioned status during a project’s construction and commissioning phases. They will be installed after each ‘Level’ has been completed and verified by the Owners Commissioning Manager.

No Tag [Level 0]

There are no tags used for the Level 0 works.

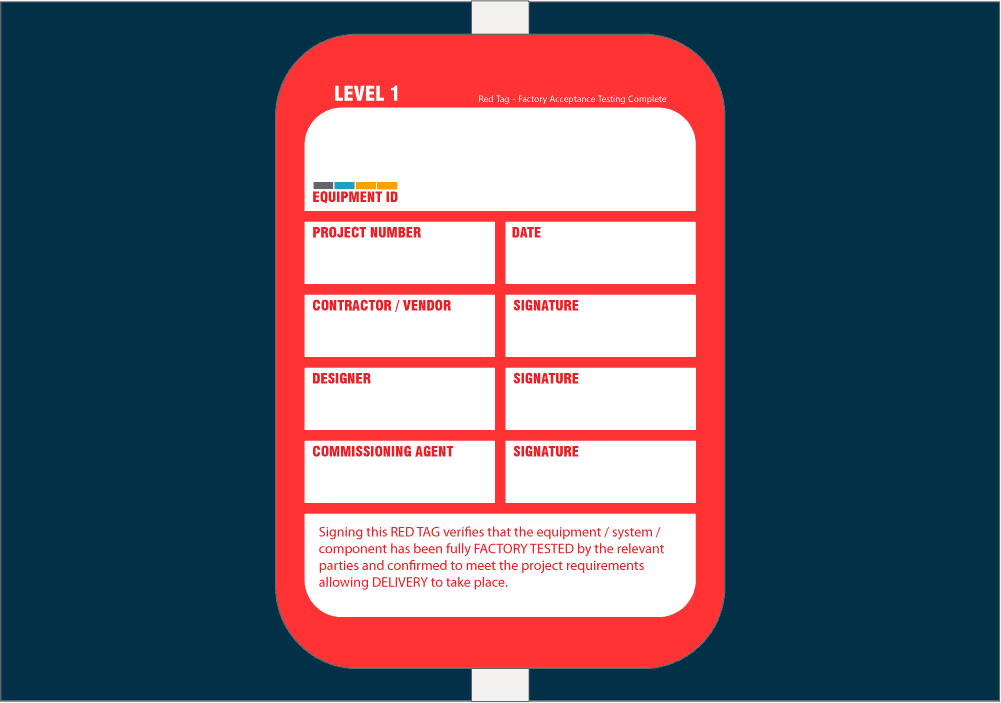

Red Tag 🟥 [Level 1]

The red tag is placed on each piece of equipment completed and passed level 1 factory testing and QA QC checks.

This indicates that the equipment meets the required standards and has been approved for installation and integration into the data center’s infrastructure.

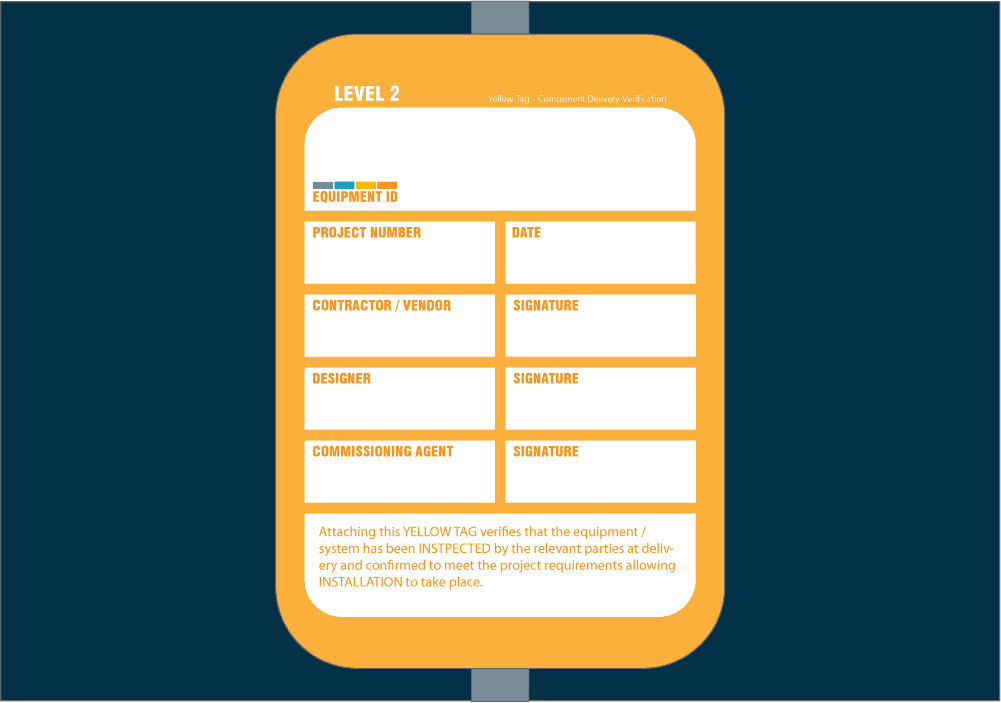

Yellow Tag 🟨 [Level 2]

At level 2, the yellow tag is used to signify the completion of component delivery, installation, and pre-startup activities.

Once all Level 2 works are completed with the tag in place, Level 3 works can commence.

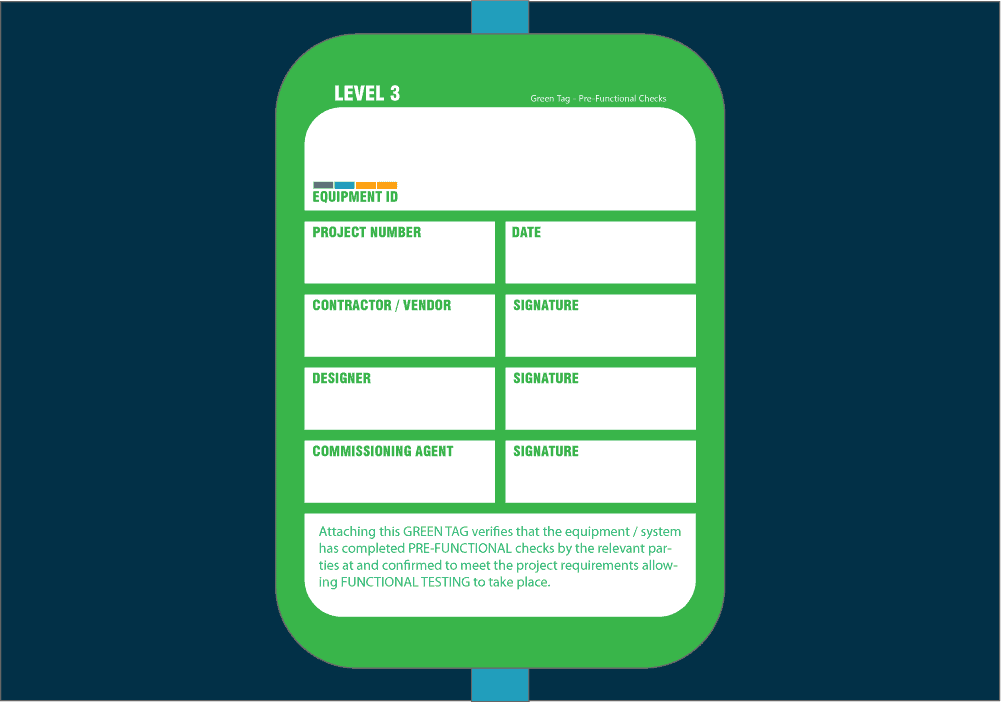

Green Tag 🟩 [Level 3]

The green tag represents level 3 commissioning. The data center enters the pre-commissioning and pre-functional energization and systems startup phase at this stage.

The green tag signifies that all the components and systems are successfully checked, energized, and started up, ready for further testing and validation at Level 4.

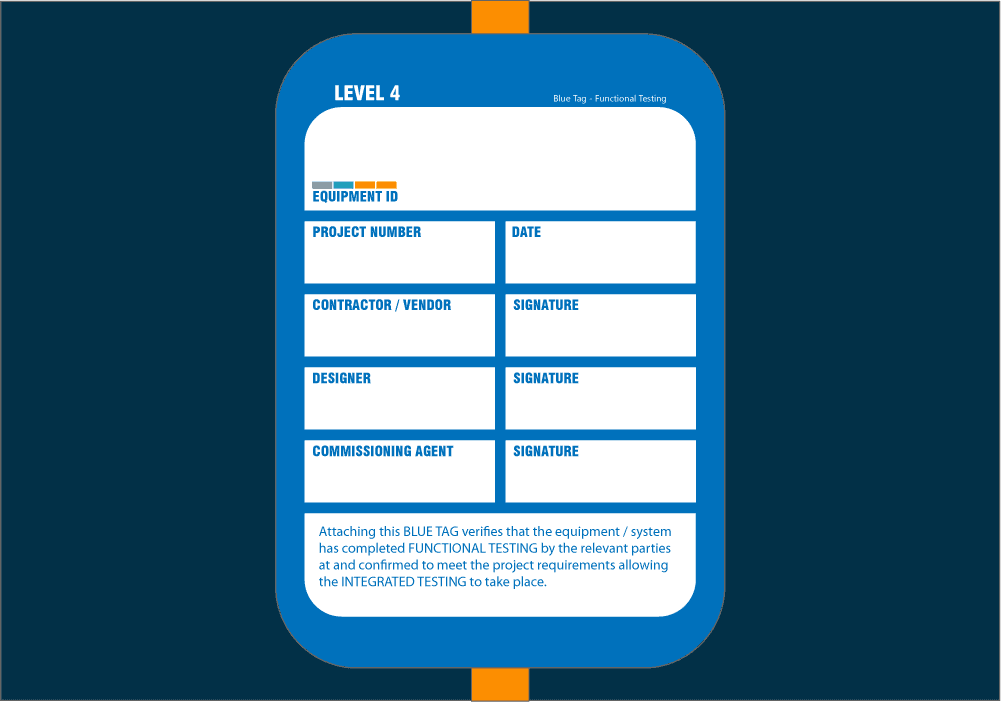

Blue Tag 🟦 [Level 4]

The blue tag is attached after the Level 4 functional testing works have been completed on the equipment and associated systems.

During this phase, various systems and equipment are subjected to rigorous testing scenarios to assess their performance, functionality, and compatibility within the data center environment before the Level 5 works commence.

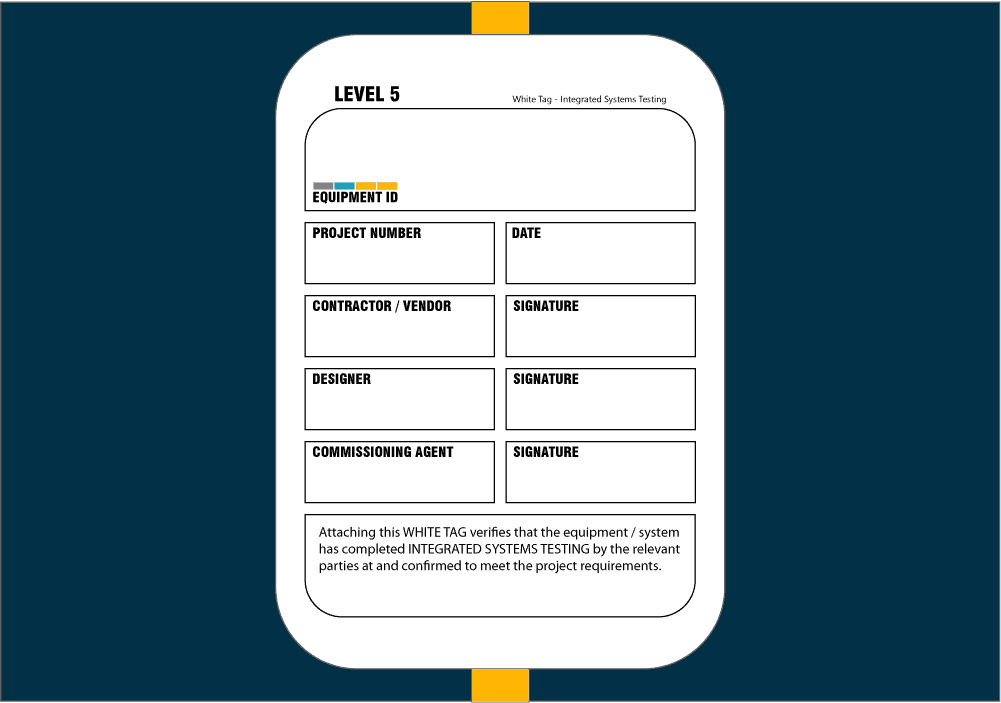

White Tag ⬜ [Level 5]

After completing the Integrated Systems Testing, a white tag will be installed on the equipment. This is the final functional testing stage integrating all systems as one, before moving to the handover/turnover stage of the process.

No Tag [Level 6]

There are no tags used for the Level 6 works.

🟧 Information to be displayed on the Tags

The information that would usually be contained on each tag would be:

- Appropriate color

- Level number

- Level reference

- Equipment ID

- Project number

- Date

- Contractor/vendor signature box

- Designer signature box

- Commissioning Agent signature box

- High-level description of the tag and next step

🔗 If want to see a typical checklist for commissioning a data center checkout our article DATA CENTER | Commissioning Checklist

⬜ Data Center Commissioning Guideline Template

🚀 The ‘Data Center Commissioning Guideline’ includes the checklists as a bonus, but if only want those then please see the end of this article where can be downloaded].

To help us expand the site and create more resources, we made the document below in [Microsoft Word] & [Microsoft Excel] for download.

Click the ‘Buy Here‘ button to purchase the fully editable copy, which can be used immediately.

🔗 To read more on what a Commissioning Guideline is and how to write one, see our article | DATA CENTER | Commissioning Guideline Template

You will be directed to our shop page.

⬛ Level 0 – Design and Planning Activities

At Level 0 of the commissioning process, managed by the General Contractor and Owners Commissioning Consultant, the focus is on laying the foundation for a successful commissioning process to be deployed.

The level involves evaluating, planning, and documenting necessary information and tasks, with key requirements at this level including:

🔗 To read our detailed GUIDE for delivering Level 0 including all tasks and activities see our article | LEVEL 0 – DATA CENTER COMMISSIONING | Design & Planning

⬛ Formation of a Competent and Dedicated Commissioning Team

Assembling a skilled team with defined roles and responsibilities to ensure effective coordination and accountability.

⬛ Development of a Comprehensive 100% Design

Ensuring the project’s design encompasses all requirements and specifications, accounting for necessary systems and components for successful commissioning.

⬛ Performing Design Reviews

Conducting thorough design reviews to verify that systems and equipment facilitate pre-commissioning and functional testing, meeting the overall project requirements, industry standards, and regulations.

⬛ Conducting Single Point of Failure Reviews

Identifying vulnerabilities in redundant systems and implementing measures to enhance system resilience if anything is discovered.

⬛ Establishment of a Clear Commissioning Process

Defining a transparent commissioning process with activities, milestones, and deliverables for each project stage and gaining stakeholder agreement.

⬛ Conducting Productive Meetings and Workshops

Engaging relevant stakeholders in productive sessions to address design considerations, technical challenges, and integration issues.

⬛ Discussion and Agreement on Commissioning Document Expectations

Reaching agreement on commissioning document expectations and establishing templates and guidelines for documenting the commissioning activities, factory testing, and onsite testing.

⬛ Defining and Agreeing Upon Requirements for Factory Testing

Clearly defining and agreeing upon specific requirements for factory testing of equipment.

⬛ Create, Issue, and Approval of Commissioning Documentation

Creating comprehensive commissioning documentation covering all project levels and ensuring accuracy and completeness before issuing it for approval.

⬛ Tag Installation

There will be NO TAGS provided on completion of this stage.

🟥 Level 1 – Factory Testing Activities

Overseen by the General Contractor, the factory testing involves testing the selected plant and equipment at the vendor’s factory and completing any QA/QC checks on equipment that is not tested.

Key responsibilities and activities at this stage include:

🔗 To read our detailed GUIDE for delivering Level 1, see our article | LEVEL 1 - DATA CENTER COMMISSIONING | Factory Testing

🟥 Conducting Equipment Factory Testing

Executing approved testing procedures on the selected equipment to validate functionality, performance, and adherence to project requirements. Detailed documentation of the testing process is essential.

🟥 Performing Equipment Quality Assurance/Quality Control Checks

Implementing rigorous checks to ensure the equipment meets design and operational requirements on equipment not factory tested via visual inspections to identify defects or damages.

🟥 Generating Reports and Gathering Data

Compiling detailed reports with test results and findings for each piece of equipment tested.

🟥 Coordinating Equipment Shipping

Overseeing the logistics of shipping the equipment, ensuring proper packaging and handling.

🟥 Tag Installation

Upon equipment arrival at the site, attach the Level 1 🟥 [Red] Tag following established equipment management and traceability protocols.

🔗 We have written more detail regarding Factory Acceptance Testing in our Article | A Complete Guide To Factory Acceptance Testing

🟨 Level 2 – Component Delivery, Installation & Pre-Startup/Pre-Commissioning Activities

In Level 2 of the data center commissioning process, managed by the General Contractor, the main goal is to ensure successful delivery, installation, and pre-start-up/pre-commissioning checks of all equipment, plant, and components to ensure they meet the project requirements and can be energized in the next level.

🔗 To read our detailed GUIDE for delivering Level 2, see our article | LEVEL 2 – DATA CENTER COMMISSIONING | Component Delivery

The primary focuses during the Level 2 works are:

🟨 Component, Equipment, and Material Compliance

Verify that all delivered components align with project requirements, are undamaged, and meet specified standards. Cross-referencing with the project documentation to confirm accuracy and suitability.

🟨 Installation Conformance and Quality

Validate that installations adhere to construction drawings, complying with project specifications and requirements. This is completed via quality checks to ensure workmanship and accuracy.

🟨 Pre-Start-up Checks and Readiness

Perform comprehensive pre-startup checks to ensure systems are ready for the Level 3 works to commence. Verify that connections, settings, and configurations align with the design requirements of the various systems, equipment, and subsystems.

🟨 Completion of Static/Pre-Commissioning Works and Testing

Ensure works, such as pressure testing, pipework cleaning, rotational checks, dead testing, and earthing testing, are completed.

🟨 Tag Installation

Once each piece of equipment has been delivered and installed correctly with the pre-commissioning checks complete, the Level 2 🟨 [Yellow] tag can be attached, following established protocols for equipment management and traceability.

🔗 We have written more on delivery checks in our article 3 Types of Commissioning Checklists, in the section for the construction checks, we cover the delivery requirements for various systems and equipment.

🟩 Level 3 – Systems Start-up Activities

Managed by the General Contractor, Level 3 focuses on starting up/energizing individual plant, equipment, systems, and components, ensuring they operate in line with design intent and approved procedures.

This stage is crucial before Level 4 and Level 5 work to ensure that the systems are operating as expected. A high-level overview of Level 3 being:

🔗 To read our detailed GUIDE for delivering Level 3, see our article | LEVEL 3 – DATA CENTER COMMISSIONING | Pre-Functional/Start-Up

🟩 Energization & Start-up of Equipment

Methodically energize and start up designated equipment following specified procedures and safety protocols, ensuring correct power-up and necessary adjustments based on design requirements.

🟩 Inputting and Validating Specific Settings

Input and validate specific settings for equipment and systems, verifying accuracy and functionality through testing and monitoring.

🟩 General Site Testing

Perform comprehensive site testing to verify overall functionality, integration, and performance of systems and equipment, including power supply, cooling, and controls.

🟩 Documenting All Level 3 Tasks and Activities

Maintain accurate documentation of all Level 3 tasks, including start-up procedures, test results, configuration changes, and adjustments.

🟩 Closure of Issues and Observations

Address and close out any issues or observations identified during Level 3 and those from previous levels.

🟩 Readying Systems for Level 4 Functional Testing

Prepare systems for Level 4 functional testing, ensuring they meet readiness criteria, stability, configuration accuracy, and operational reliability.

🟩 Tag Installation

Once each piece of equipment has been started up correctly with all checks completed, the Level 3 🟩 [Green] tag can be attached, following established equipment management and traceability protocols.

🟦 Level 4 – Component / System Functional Performance Testing Activities

Managed and delivered by the Owners Commissioning Consultant, with support from the General Contractor, Level 4 focuses on integrating systems and conducting rigorous tests to them ensuring alignment with project requirements:

🔗 To read our detailed GUIDE for delivering Level 4, see our article | LEVEL 4 – DATA CENTER COMMISSIONING | Functional Testing

🟦 Operating Modes of Equipment Performing as Expected

Validate that equipment operates as intended and meets specified performance criteria under various scenarios, including failure scenarios, load testing chillers, and electrical infrastructure.

🟦 Interlocks of Equipment and Systems Performing as Expected

Verify that interlocks within equipment and systems function correctly, ensuring safety mechanisms and control logic operate as designed.

🟦 Sequence of Operations of Equipment and Systems Performing as Expected

Conduct tests to evaluate the sequence of operations of the plant, equipment, and systems, ensuring they follow predetermined designs and control documentation.

🟦 Documenting All Level 4 Tasks and Activities

Maintain accurate documentation of Level 4 tasks, including test results, configurations, and adjustments.

🟦 Closure of Issues and Observations

Address and resolve any identified issues from Level 4 and previous levels.

🟦 Readying Systems for Level 5 Integrated Testing

Prepare systems for Level 5 integrated testing, ensuring proper configuration and optimization for comprehensive testing.

🟦 Conducting Training

Comprehensive training sessions are conducted for the facilities teams, equipping them with the knowledge and skills to operate and maintain the data center effectively.

🟦 Tag Installation

Once the works have been completed, the Level 4 🟦 [Blue] tag can be attached, following established equipment management and traceability protocols.

- Use Straight Away

- Insert in Tender Documents

- Industry Wide Process from Level 0 to Level 6

- Detailed Responsibility and Roles

- Includes Commissioning Checklist

Aimed at anyone who needs a detailed delivery plan and checklist for deploying Commissioning within a Data Center Project, this document is formatted in Microsoft Word/Excel and written so that it can be deployed quickly and easily with minimal updating to suit your specific needs.

[Once through to the shop there is a sample of the document to view]

- Easy

- Quick

- High Level

- Tracker

Here is our open copy [MS Word] & [MS Excel] of the Data Center Commissioning Checklist, for making life a little easier...

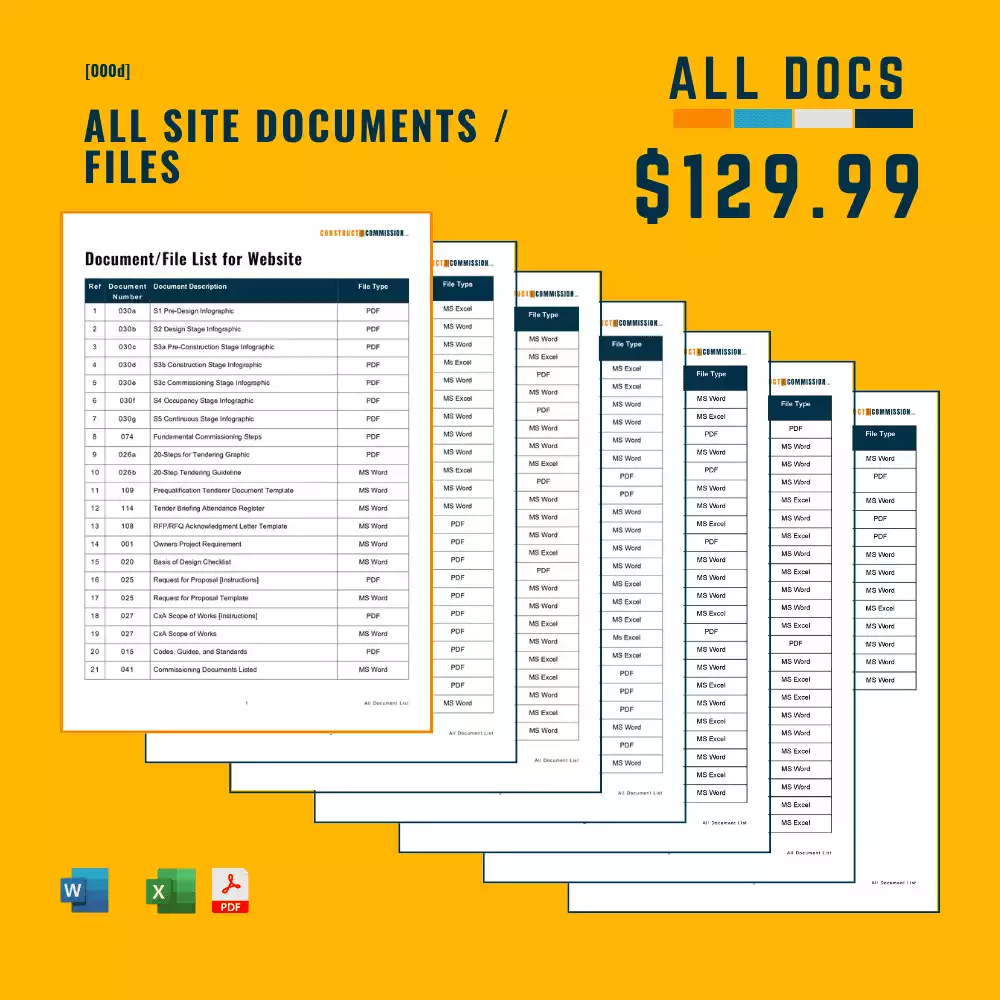

- 126No. Documents

- Use Straight Away

- Amazing Value

We have been asked several times to create a complete document package covering everything we have uploaded to the site.

So it's taken some time, but here it is....126No. Documents for you to download in Microsoft Word, Microsoft Excel & PDF Formats.

CLICK THE BUY HERE TO SEE/DOWNLOAD A FULL LIST OF DOCUMENTS INCLUDED...

⬜ Level 5 – Integrated System Testing Activities

Managed by the Owners Commissioning Consultant with support from the General/Main Contractor, Level 5 is the final step in validating the performance of installed systems.

It focuses on integrating all systems and conducting rigorous tests to evaluate functionality, interoperation, and response to failure scenarios and aims to demonstrate seamless operation in line with the owner’s project requirements [OPR], Basis of Design [BOD], and contractual documentation.

🔗 To read our detailed 16 STEP GUIDE for delivering Level 5, see our article | LEVEL 5 – DATA CENTER COMMISSIONING | Integrated Testing

Key aspects of Level 5 are:

⬜ Integrated Testing Scripts

Develop and issue testing scripts outlining specific procedures and scenarios for testing phase execution.

⬜ Meetings, Workshops, and Reporting

Conduct productive meetings involving relevant stakeholders to review progress, address concerns, and report on testing activities.

⬜ Organization of Permits

Obtain necessary permits and approvals for integrated systems testing.

⬜ Load Bank Plans and Temporary Instruments/Equipment

Ensure load bank plans and temporary instruments align with testing objectives and replicate anticipated load demands.

⬜ Resource Schedules

Establish comprehensive schedules for personnel, equipment, and materials required for testing.

⬜ Integrated Systems Testing

Execute rigorous testing procedures to evaluate system performance, functionality, and interoperation.

Heat load testing is completed to prove that the thermal response of the data hall under different heating load conditions and failure scenarios is within the tolerances stipulated by design.

Electrical Integrated Testing is completed to prove that upon failures across the electrical systems and incoming utility supplies, the use of the data center will not be affected and will maintain its operating status with no downtime.

⬜ Document Filing

Maintain documentation throughout Level 5, including test plans, results, data trends, and adjustments.

⬜ Final Level 5 Integrated Testing Report and Closeout Meeting

Prepare a comprehensive report consolidating findings, observations, and results. Conduct a closeout meeting to address outstanding issues and gain consensus among stakeholders.

⬜ Completing Training

Conclude training sessions for facilities teams, ensuring they have the necessary data center operation and maintenance knowledge and skills.

⬜ Tag Installation

Once the works have been completed, the Level 5 ⬜ [White] tag can be attached, following established equipment management and traceability protocols.

⬛ Level 6 – Closeout / Turnover / Handover Activities

Some clients will request this level to allow a controlled closeout of the project; it will usually involve creating a handover document and working through it.

Managed and executed by the Owners Commissioning Consultant, with support from the General Contractor, Level 6 is the final stage of the Data Center Commissioning Process. It involves transitioning the facility and its systems to the Owner and Facilities Team, ensuring complete preparation and optimized for operation.

🔗 To read our detailed 9 STEP GUIDE for delivering Level 6, see our article | LEVEL 6 – DATA CENTER COMMISSIONING | Closeout & Turnover

Key objectives and outcomes include:

⬛ Completing Final Handover Documentation

Compile and organize all required documentation for a smooth handover process, including manuals, drawings, warranties, and records.

⬛ Conducting Site Walk and Final Inspection

Thoroughly inspect all areas of the data center to ensure compliance with standards. Address and rectify any outstanding issues.

⬛ Closing out Issues and Observations

Address and resolve any remaining issues from previous commissioning levels to ensure all tasks are completed.

⬛ Deep Cleaning of Data Hall

If not done earlier, conduct a comprehensive deep cleaning of the data hall to provide an optimal environment for critical equipment.

⬛ Verification of Plant and Equipment Settings

Verify settings and configurations of plant and equipment align with design intent and operational requirements.

⬛ Lessons Learned

Conduct a session to evaluate the commissioning process, documenting insights and recommendations for future improvement.

⬛ Conducting Closeout Meeting

Meet with stakeholders to review the commissioning process, discuss results, and obtain necessary approvals.

⬛ Issuing Final Commissioning Report

Prepare a comprehensive report documenting the commissioning journey, including activities, results, and recommendations.

⬜ Level 0 to Level 6 Data Center Commissioning Checklist

To help us expand the site and create more resources, we created the documentation below in [Microsoft Word] & [Microsoft Excel] for download.

Click the ‘Buy It Now‘ button to purchase the fully editable copy of the document below, which can be used immediately.

You will direct to our shop page.

⬛ Related Articles

CRAH UNIT | Pre-Functional CheckList

DATA CENTER TIERS | 1, 2, 3 & 4 Explained with Downloads

CRAH UNIT | Functional Testing Example + Template

CRAH UNITS | What are they?

LEVEL 6 – DATA CENTER Cx | Turnover & Handover

DATA CENTER | Commissioning Guideline & Template

![Data Center Commissioning Checklist [MS Word] & [MS Excel]](https://constructandcommission.com/wp-content/uploads/2023/07/066-Data-Center-Commissioning-Checklist-Shop.webp)