To ensure that any major/critical equipment on a project meets its intended operational requirements, a factory test will typically be conducted before delivery to the site. The test will evaluate the equipment’s operation against its approved manufactured and operational data, which can normally be found within its technical/material submission or the equipment datasheets.

Once the factory acceptance testing has been completed successfully, the associated equipment will be approved to be shipped and delivered to the site for installation.

🟩 What is the reason for completing a Factory Acceptance Test?

Factory Acceptance Testing is used to ensure that, before dispatch to the site/project, there is no manufacturing, build quality, or performance issues with the equipment based upon the approved documentation, such as:

- Manufacturers drawings

- Data Sheets

- Specifications

- Material/Technical Submissions

- Testing Method Statement

If the testing is not completed, and there are noted issues when delivered to the project, these could cause huge implications related to:

- Programme

- Owners Project Requirements

- Design

- Operation

🟩 What is the difference between Factory Acceptance Testing and Site Acceptance Testing?

The main difference between the two is how the testing is completed.

During a factory test for HVAC equipment especially, the testing is usually completed under stringent conditions within a chamber that is equipped with instrumentation to allow remote monitoring and reporting of data.

| Factory Testing | Site Testing | |

|---|---|---|

| Location: | At Factory [another country] | On-Site |

| Programme Time Required: | Short | Usually Longer |

| The Extent of Testing: | Detailed specific to the equipment | Detailed to the equipment but also can include integration with other systems |

| Testing Environment: | Mainly completed by installing HVAC components/equipment into a purpose-built chamber so that ambient conditions can be controlled and simulation conducted. | Equipment installed onsite, infield testing, limited ability to change ambient conditions if needed. |

| Reporting: | Usually, due to how the equipment and systems are set up and connected to instrumentation, reports, documentation, and data can be very detailed. | Generally find less information can be provided at site testing. If combined with the Factory information, then it provides a good understanding of the equipment. |

🟩 When is Factory Acceptance Testing required?

Not all Plant and Equipment on a project will need to be factory tested. It will depend on the requirements set out in the Owners Project Requirements [OPR] and Commissioning Plan/Specification.

Generally, the testing would be needed if it is a complex piece of equipment or something that would severely impact the completion of the facility’s project or operation if not manufactured or working correctly upon installation, commissioning, and handover/completion.

To save any cutting and pasting, we have made available our Factory Testing Report, which can be downloaded in [MS WORD] for easy editing.

🟩 Factory Acceptance Test Duration

Testing duration will depend upon what type of plant and equipment is being reviewed. They can usually range from 1 day to 3 days.

🟩 Factory Acceptance Test Costs

As with the testing duration, costs will fully depend upon the following:

- Type of equipment [more complex the equipment = more $]

- Quantity of each type of equipment [more of each type = more $]

- Location of testing, some can be long distances/other countries [further away = more $]

- Quantity of people to attend at the factory [more people = more accommodation = more travel = more $]

- How many days will the testing take to complete [more days = more $]

🟩 Responsibilities for the FAT

There will be various team members involved with the testing at the different stages, below provides a general example of tasks and responsibilities:

| Description | Responsible | Document |

|---|---|---|

| Select Equipment to be tested | Client Commissioning Consultant MEP Designer | Owners Project Requirements [OPR] Commissioning Spec Commissioning Plan |

| Specify Testing that should be completed as a minimum | Commissioning Consultant MEP Designer | Commissioning Spec Commissioning Plan |

| Specify who should be in attendance for the testing | Commissioning Consultant | Commissioning Spec Commissioning Plan |

| Costing schedule for testing [testing, instruments, documents, transport, accommodation, meals, local travel, etc] | Main Contractor General Contractor | Commissioning Spec Commissioning Plan |

| Format of documents [factory testing method statement, Reports] | Commissioning Consultant | Commissioning Spec Commissioning Plan Standard document format |

| Agreeing if FAT witnessing is to be conducted remotely or at the factory | Commissioning Consultant Main Contractor General Contractor | n/a |

| Ensure Factory has the resource and ability to conduct the required testing with all equipment and data reporting tools | Main Contractor General Contractor | n/a |

| Managing and Writing Testing Method Statement/Script | Main Contractor General Contractor | FAT Method Statement |

| Review and Approve Testing Method Statement/Script | Commissioning Consultant MEP Designer | Comment report |

| Coordinate relevant parties on the Dates, Location, Travel Arrangements, Accommodation, etc | Main Contractor General Contractor | Itinerary Document |

| 7 days prior to FAT, confirm factory is ready and all equipment/instruments are available | Main Contractor General Contractor | |

| At Factory, manage and coordinate all testing between parties, obtain all Calibration Certificates | Main Contractor General Contractor | FAT Method Statement |

| Conduct all testing and monitoring/recording information | Main Contractor General Contractor Factory | Data Sheets |

| Write/update and manage the observation/defect list | Commissioning Consultant Main Contractor General Contractor | Issue Register |

| Once testing completed, agree and provide a certificate that the equipment has successfully passed the testing [subject to observations] and can be shipped | Commissioning Consultant | Able to ship certificate |

| Write FAT report in line with project requirements, including all data and certification etc. | Commissioning Consultant Main Contractor General Contractor | FAT Report |

| Review and approve Factory Test Report | Commissioning Consultant MEP Designer | Comment Report |

| Manage and closeout observations/defects | Commissioning Consultant MEP Designer Main Contractor General Contractor | Issue Register |

🟩 How do you write a Factory Acceptance Test Method Statement?

Managed by the Main/General Contractor and generally written by the Manufacturer, the Factory Acceptance Method Statement should be created after the material/technical submission for the particular equipment and plant has been approved, by the design consultant.

As a commissioning engineer/manager the most efficient way to write and review documents is if they are all created in the same format.

The below details a format that can be used and specified in the commissioning plan/specification to ensure the whole project provides the required format.

| Section | Details |

|---|---|

| Front Cover | Front Cover detailing project Information |

| Contents | Page of Contents |

| Revision | Revision History Page |

| 1 | Introduction for the testing |

| 2 | Reference information used to create the document [guides, codes, standards, regulations, drawings, etc.] |

| 3 | Dates, times, and location of the testing |

| 4 | List of equipment/instrumentation to be used during the test with Calibration details |

| 5 | Pre-Requisites |

| 6 | System testing information [pressures, times, tolerances, etc] |

| 7 | Drawings/images/plans/documentation of factory testing set up and instruments |

| 8 | Details of remote testing set up [computers, screens, cameras] including setup plan |

| 9 | Programme/sequence of Testing |

| 10 | Method of testing & any tables and information to be completed during testing reports from instruments |

| 11 | Calibration certificates of all equipment and instruments attached |

🟩 Factory Acceptance Test Checklist

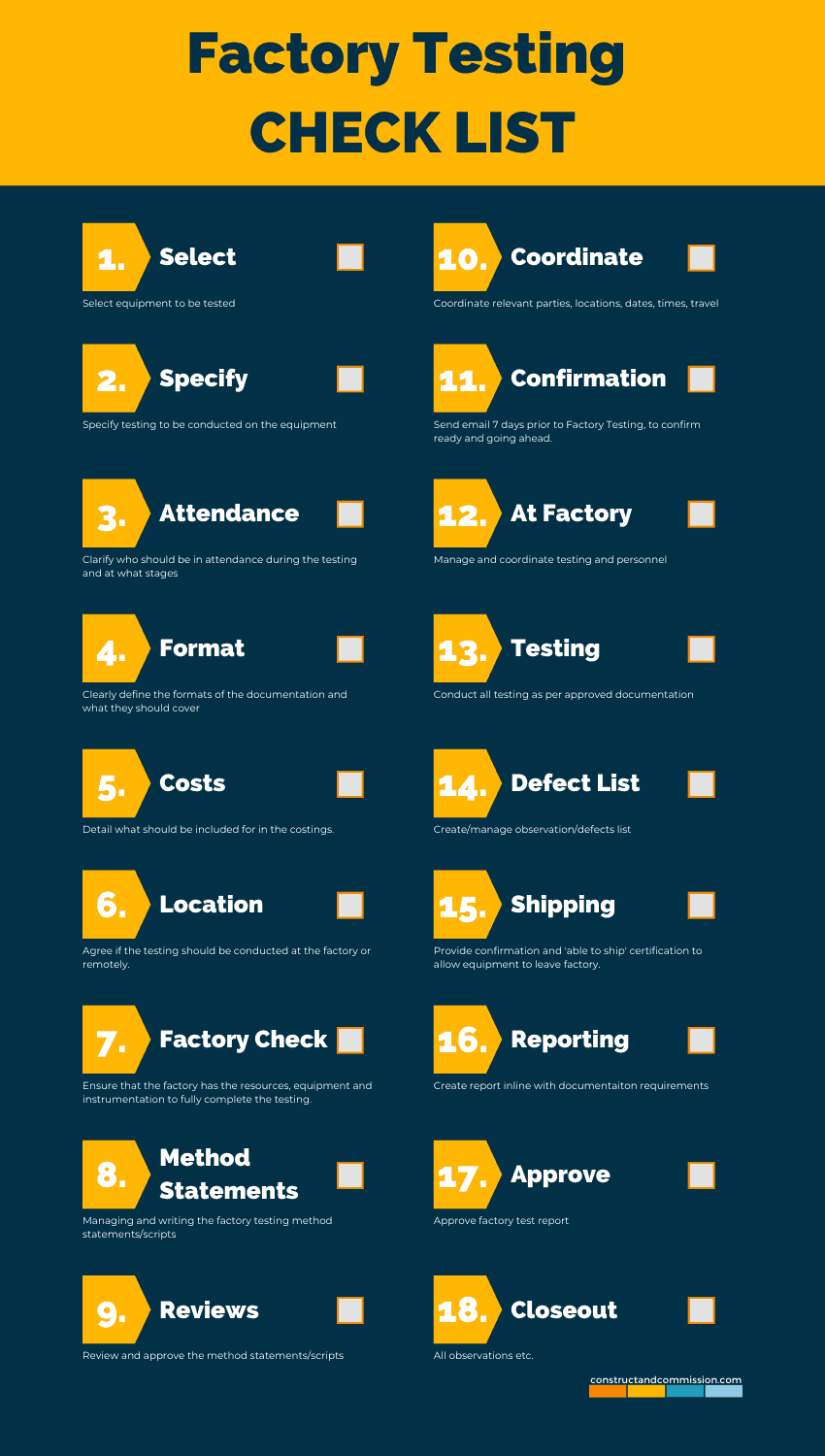

Checklists are always helpful, and the below checklist can be used to help plan and execute your test:

| Ref | Description | Responsible |

|---|---|---|

| 1 | Select Equipment to be tested in Owners Project Requirements [OPR], Commissioning Spec, Commissioning Plan | Client / Commissioning Consultant |

| 2 | Specify Testing that should be completed as a minimum in the Commissioning Spec, and Commissioning Plan for tender documents and pricing. | Commissioning Consultant MEP Designer |

| 3 | Specify who should be in attendance for the testing in the Commissioning Spec, and Commissioning Plan for tender documents and pricing. | Commissioning Consultant |

| 4 | Specify Format of documents [factory testing method statement, Reports] in the Commissioning Spec/Commissioning Plan for tender documents and pricing | Commissioning Consultant |

| 5 | Costing schedule for testing [testing, instruments, documents, transport, accommodation, meals, local travel, etc], in the Commissioning Spec/Commissioning Plan for tender documents and pricing. | Main Contractor General Contractor |

| 6 | Agreeing if FAT witnessing is to be conducted remotely or at the factory | Commissioning Consultant Main Contractor General Contractor |

| 7 | Ensure Factory has the resource and ability to conduct the required testing with all equipment and data reporting tools | Main Contractor General Contractor |

| 8 | Managing and Writing Testing Method Statement/Script | Main Contractor General Contractor |

| 9 | Review and Approve Testing Method Statement/Script | Commissioning Consultant MEP Designer |

| 10 | Coordinate relevant parties on the Dates, Location, Travel Arrangements, Accommodation, etc and issue itinerary document | Main Contractor General Contractor |

| 11 | Send email 7 days prior to FAT, confirm factory is ready, all equipment/instruments are available and details of travel and accommodation to client and consultant team | Main Contractor General Contractor |

| 12 | At Factory, manage and coordinate all testing between parties, obtain all Calibration Certificates | Main Contractor General Contractor |

| 13 | Conduct all testing and monitoring/recording information | Main Contractor General Contractor Factory |

| 14 | Write/update and manage the observation/defect list | Commissioning Consultant |

| 15 | Provide 'able to ship' certificate confirming that testing was completed successfully, and can be shipped | Commissioning Consultant |

| 16 | Write FAT report in line with project requirements, including all data and certification, etc. | Commissioning Consultant Main Contractor General Contractor |

| 17 | Review and approve Factory Test Report | Commissioning Consultant MEP Designer |

| 18 | Manage and closeout observations/defects on issue register | Commissioning Consultant MEP Designer Main Contractor General Contractor |

Including fully editable versions of our Commissioning Daily, Weekly, Monthly, Final, and Factory Reports

🟩 Factory Acceptance Test Agenda and Set-Up

To be organized means to be efficient so the agenda below can be used to help run the testing day:

| Ref | Description |

|---|---|

| 1 | Pick up from accommodation |

| 2 | Transport to factory |

| 3 | Sign in and security checks at the factory |

| 4 | Camera/Wifi/internet connection checks [if conducting remotely] |

| 5 | Briefing on testing for the day |

| 6 | Calibration certificate checks of all equipment and instruments |

| 7 | Pre-Requisite checks |

| 8 | Start morning testing |

| 9 | Lunch |

| 10 | Start afternoon testing |

| 11 | Finish testing for the day |

| 12 | Debrief and run through observations |

| 13 | Transport back to the accommodation |

| 14 | Dinner |

🟩 Factory Acceptance Test Report Template

Like with the testing procedure, the reports should be written in a standard format to allow efficient reviews and ensure that the relevant information is contained.

The requirement of the format and information should be detailed within the following documents, to ensure a clear direction is provided to the contractors/manufacturers during the tender process:

- Commissioning Plan

- Commissioning Specification

Obviously, there is scope to be flexible, but the ultimate aim as noted is to be efficient and ensure that the project understands the correct information to be included.

To save any cutting and pasting, we have made available our Factory Testing Report, which can be downloaded in [MS WORD] for easy editing.

Below is a format that can be used/modified to suit your requirements; it contains responsibilities from different parties to ultimately write and approve the document.

- Written and managed by Main/General Contractor

- Added to by Commissioning Consultant

- Approved by Commissioning Consultant & MEP Designer

| Section | Description | Responsible |

|---|---|---|

| 1 | Executive Summary | Commissioning Consultant |

| 2 | Introduction | Main/General Contractor |

| 3 | List of Attendees | Main/General Contractor |

| 4 | Table of observations/outcomes | Main/General Contractor Commissioning Consultant MEP Designer |

| 5 | Main Report | Main/General Contractor Factory |

| 6 | Conclusion | Main/General Contractor Factory |

| App 1 | Sign Off Certificate | Commissioning Consultant |

| App 2 | Design Intent/Performace Specification/Approved Method Statement | Main/General Contractor Factory |

| App 3 | Test Results/Data Tables | Main/General Contractor Factory |

| App 4 | Calculations | Main/General Contractor Factory |

| App 5 | Computer Printouts | Main/General Contractor Factory |

| App 6 | Calibration Certificates | Main/General Contractor Factory |

| App 7 | Drawings | Main/General Contractor Factory |

| App 8 | Record Photographs | Main/General Contractor Factory |

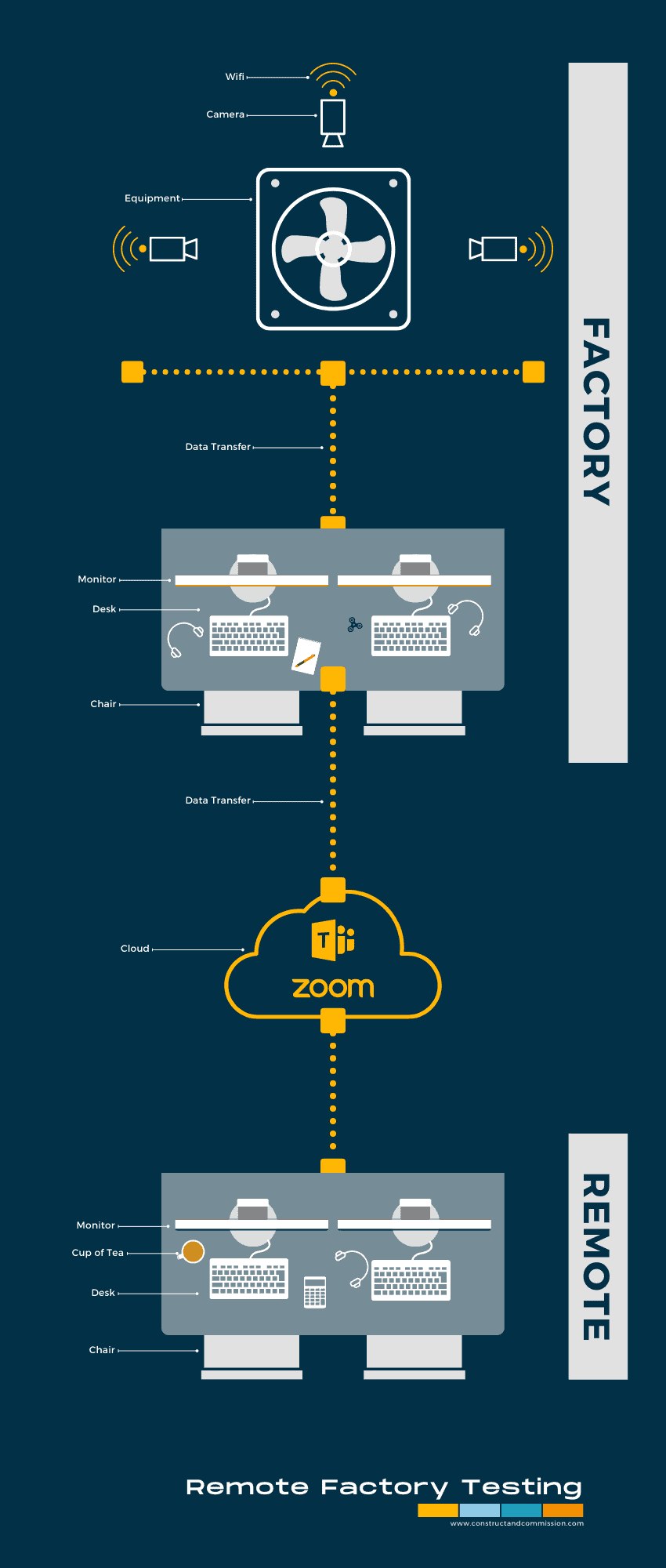

🟩 Remote Factory Testing Infographic

-END-

⬜ Factory Acceptance Testing Report Template [MS Word]

To help us expand the site and create more resources, we have created the below documentation in [Microsoft Word] for download.

Click the ‘Buy Here‘ button to purchase the fully editable copy of the document below, which can be used straight away.

You will direct to our shop page.

⬛ Related Articles

FAN COIL UNIT | Week, Month, 6 months, Year & 4 Year Inspections Listed

FLUSHING & CLEANING | Monitoring after Flushing

CRAH UNIT | Functional Testing Example + Template

GROUP CONTROL | CRAH & CRAC Units

FIRE DAMPERS | Detailed Guide to Testing

FAN COIL UNIT | Onsite Functional Testing Procedure with Template

![Factory Testing Report Template [MS Word]](https://constructandcommission.com/wp-content/uploads/2022/12/024-PH-Factory-Test-Report-Sell.webp)

![Commissioning Report Bundle [Various]](https://constructandcommission.com/wp-content/uploads/2022/12/000b-PH-Report-Bundle-Sell.webp)