During Level 1 – Factory Testing, the General Contractor works with the Owners Commissioning Provider to ensure that the designated plant and equipment undergo thorough factory testing and QA/QC checks, ensuring that, before leaving the factory, the equipment is functioning correctly and meets the design expectations.

Although this stage is relatively short and uncomplicated, it necessitates the dedicated efforts of individuals with specialized skills and expertise.

The following provides an overview of the key responsibilities and activities undertaken during Level 1 tasks and activities:

- Conducting Equipment Factory Testing

- Performing Equipment Quality Assurance/Quality Control Checks

- Generating Reports and Gathering Data

- Coordinating Equipment Shipping

- Attaching the Appropriate Level 1 Tag

⬛ Additional Resources

To help navigate around the site and provide additional resources, we’ve added plenty of helpful links throughout this article to help you complete your data center commissioning, also below is a list of other articles that we have written that you may find helpful:

- Data Center Commissioning | What is it? including Guideline

- Data Center | 0, 1, 2, 3, 4, 5, 6 Levels of Commissioning [high-level]

- Data Center Redundancy | N, N+1, N+2, 2N & 2N+1 Explained

- Data Center Tiers | 1, 2, 3 & 4 Explained with Downloads

- Level 0 – Data Center Commissioning | Design & Planning

- Level 2 – Data Center Commissioning | Component Delivery, Installation & Pre-Start Up

- Level 3 – Data Center Commissioning | Systems Start-Up

- Level 4 – Data Center Commissioning | Functional Testing

- Level 5 – Data Center Commissioning | Integrated Testing

- Level 6 – Data Center Commissioning | Closeout & Turnover

🟩 Sampling Rate

The Owners Commissioning Team often employs a “Sampling rate” approach during Factory Testing procedures to optimize resource utilization and minimize costs. This is especially applicable in cases where a project procures multiple units of the same equipment model. Where this happens, we usually only factory test one of each type.

The “Sampling Rate” needs to be determined in the Level 0 – Design & Planning stage by the Owner and their Commissioning Provider. After reaching an agreement, these expectations should be added to the commissioning guideline, specification, and commissioning plan to inform the General Contractor and Vendors of the necessary requirements.

🚀 The following statement can be included in your requirements if needed: ‘The anticipated sampling rate for Level 1 Factory Testing is projected to involve testing each model of equipment and being witnessed by two representatives from the Owners Team [Owners Commissioning Consultant and Designer]’.

🟩 Resouces, Travel, and Accommodation

When planning the Factory Testing, consideration should be given to the Resources, Travel, and Accommodation and what needs to be included within any scope documents for the General Contractor and Vendors. This ensures that all the Owner’s expectations are met, and there are no ambiguities about how people are expected to travel, where they stay, and the resource levels to be allowed for.

Below is an example of each that can be used on most projects.

🟧 Resources

All resources should be knowledgeable and experienced in the testing that is being completed, with the following being allowed for, as a minimum, by the General Contractor, ensuring the Owner is represented at the testing:

| General Contractor | 1No. | Minimum |

| Owner Commissioning Provider | 1No. | Minimum |

| Owner or General Contractor Designer | 1No. | Minimum |

| Vendor/Manufacturer | As required | To facilite testing |

🟧 Travel

Considerations should be made for the travel arrangements of the whole commissioning team attending the testing. Distances and locations of engineers can add significant costs to the travel allowance. Items to think about would be:

- Travel Logistics

- How many engineers need to travel,

- What are the departure and return dates,

- Are there any specific travel windows or blackout dates to avoid.

- Flight Booking

- Which airports are most convenient for departure and arrival for each person,

- What airlines offer suitable routes and schedules,

- Does the Owner have any expectations or guidelines regarding travel time, are there any specific thresholds for economy, premium, and business class,

- Are direct flights available, or will layovers be necessary,

- Are there considerations for comfort, such as seat preferences or dietary restrictions,

- Are there health-related considerations, like allergies, mobility issues, or medical needs.

- Travel Documentation

- Do engineers have valid passports and necessary visas for the destination country,

- Is there a need for additional documentation like work permits, visas, or special clearances,

- Travel Itinerary

- What are the departure and arrival times for flights?

- Are there suitable options for connecting transportation (e.g., airport transfers)?

- What’s the estimated total travel time, including layovers and transit?

- Baggage Allowance

- What’s the baggage allowance for the chosen flight class,

- Are there any restrictions on carry-on or checked baggage,

- Is anyone carrying additional luggage for the testing.

- Travel Insurance

- Is travel insurance necessary to cover unexpected events, cancellations, or medical emergencies?

- Emergency Contingencies

- What’s the plan if flights are delayed, canceled, or other travel disruptions,

- Is there a designated point of contact for handling such situations.

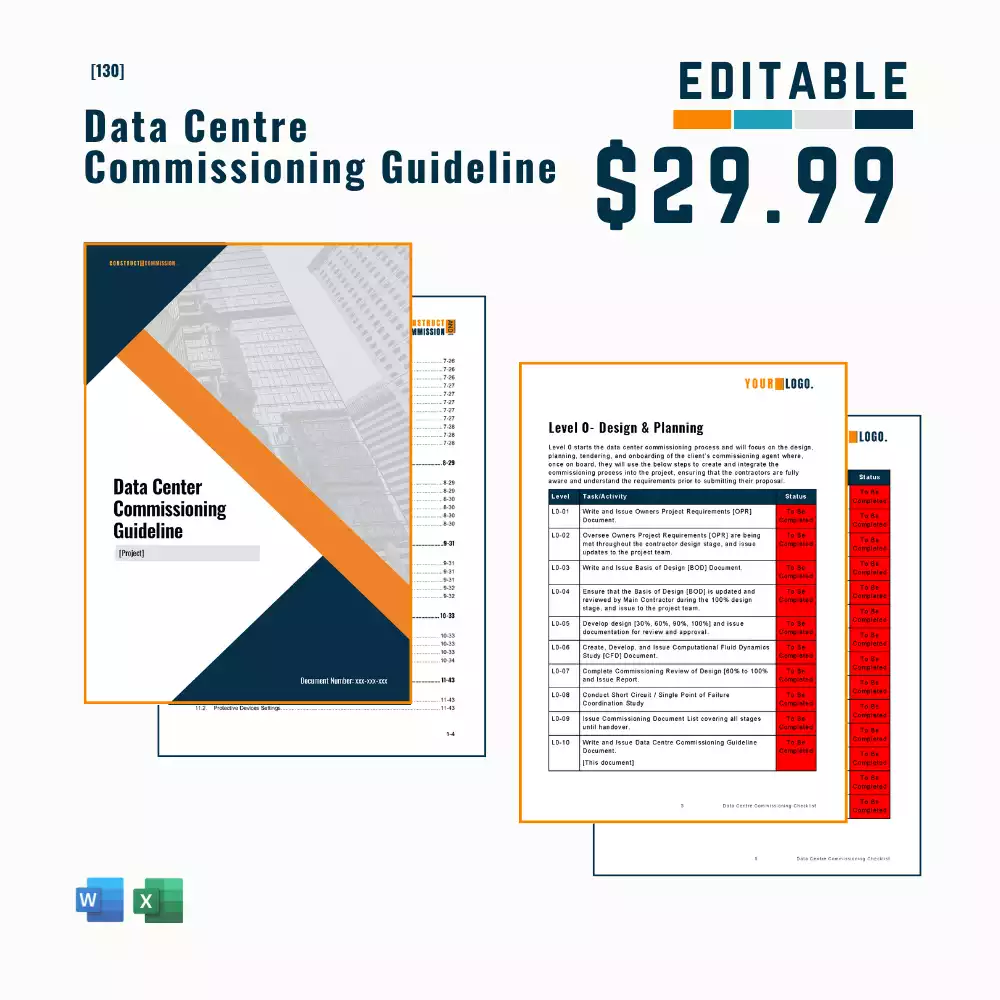

- Use Straight Away

- Insert in Tender Documents

- Industry Wide Process from Level 0 to Level 6

- Detailed Responsibility and Roles

- Includes Commissioning Checklist

Aimed at anyone who needs a detailed delivery plan and checklist for deploying Commissioning within a Data Center Project, this document is formatted in Microsoft Word/Excel and written so that it can be deployed quickly and easily with minimal updating to suit your specific needs.

[Once through to the shop there is a sample of the document to view]

- Easy

- Quick

- High Level

- Tracker

Here is our open copy [MS Word] & [MS Excel] of the Data Center Commissioning Checklist, for making life a little easier...

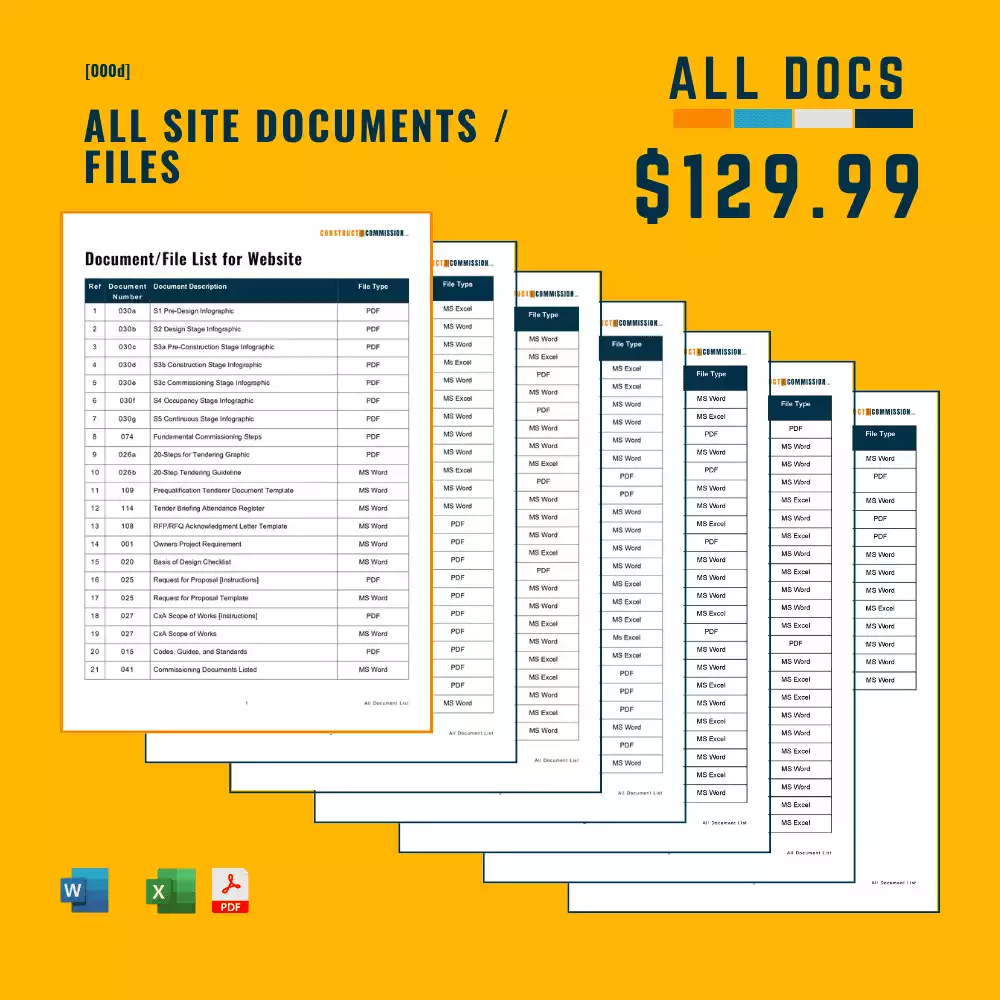

- 126No. Documents

- Use Straight Away

- Amazing Value

We have been asked several times to create a complete document package covering everything we have uploaded to the site.

So it's taken some time, but here it is....126No. Documents for you to download in Microsoft Word, Microsoft Excel & PDF Formats.

CLICK THE BUY HERE TO SEE/DOWNLOAD A FULL LIST OF DOCUMENTS INCLUDED...

🟧 Accommodation

Same for the accommodation, the following should be considered when planning and budgeting for it:

- Accommodation Logistics

- How many engineers require accommodation,

- What are the check-in and check-out dates.

- Accommodation Type

- Are hotels, serviced apartments, or other types of lodging preferred,

- What level of comfort and amenities are necessary.

- Proximity to Factory

- How far is the accommodation from the factory where testing will occur,

- Is transportation between the accommodation and factory readily available.

- Booking Channels

- How will the accommodations be booked (e.g., through a travel agency, online platform, or direct booking).

- Budget and Cost Management

- What’s the allocated budget for accommodation expenses,

- Are there cost-saving options like corporate rates or discounts for extended stays.

- Amenities and Facilities

- What amenities are essential, such as Wi-Fi, workspace, gym, or dining options,

- Are there any specific facilities needed for relaxation or recreation.

- Cultural and Local Considerations

- Are there any cultural norms or practices to respect in the destination country’s lodging,

- Are there safety or security considerations for the chosen area.

- Reservation Flexibility:

- Are there cancellation policies or reservation modifications to be aware of,

- Is there a need for a flexible booking in case of extended testing.

- Meals and Dietary Requirements:

- Is breakfast included, or are there meal options on-site or nearby,

- What is the plan for dinner,

- Are there dietary restrictions or preferences to accommodate.

🟩 Equipment to be Factory Tested

During the Level 0 – Design & Planning tasks and activities, the Owner will discuss and agree with their Commissioning Provider on the equipment to be factory tested during the Level 1 works.

This information should then be added to the commissioning guideline, specification, and commissioning plan to inform the General Contractor and Vendors of the expected requirements.

Some examples of equipment that are usually tested would be:

- Electrical equipment: High Voltage Switch Board | Electrical Transformer | Low Voltage Switch Board | Diesel Generators | Fuel Tank | Generator Switch Board | Uninterruptable Power System [UPS] | Ring Main Unit | Static Transfer Switch [STS] | etc.

- Mechanical Equipment: Cooling Tower | Chiller | Pumps | CRAC/CRAH Unit | Fan Wall Unit | Air Handling Unit | Heat Exchanger, etc.

- Controls/BMS: Chiller Control Logic | Sequence of Operations | etc.

🟩 Using the RASCI Matrix

For the roles and responsibilities, we will utilize the RASCI format, which helps with defining and communicating the required roles and responsibilities within the process and will dictate, via a structured framework, who is Responsible, Accountable, Supportive, Consulted, and Informed for each task, activity, or decision.

Using the matrix will enhance management and teamwork, promoting clarity, reducing confusion, and fostering effective communication.

| Responsible | [R] | This is the person that is responsible for doing the work ensuring the activities are completed by the relevant team members, they can also provide comments as well. |

| Approve | [A] | This person comments, approves and signs off and owns the activity. |

| Supportive | [S] | Persons who will provide support to the Responsible party, aiding in completion of the task. |

| Consulted | [C] | Opinion sought, where required. |

| Informed | [I] | This person is informed when a decision is made, or an activity is performed. They may be required to act because of the outcome. |

🟩 Roles of Team Members

The following participants will be involved in the delivery of the Level 1 – Commissioning Tasks and Activities:

| Owner | [O] | The owner is the person who will own/occupy or run the facility once it is complete; they have the final say in the overall expectations of the project and finance it. |

| Building Operator | [BO] | The company and people responsible for operating the facility once handed over. |

| Project Manager | [PM] | The project manager, employed to represent the owner, running and managing the overall project and programme. [where owner is not fully involved in the day to day running of the project]. |

| Commissioning Provider | [CxP] | The consultant employed by the Owner to ensure that the project is verified to meet their expectations, |

| Designer | [DES] | Responsible for taking the Owner's expectations/requirements and creating a design that works in line with them, |

| General Contractor | [GC] | The company employed to construct, build and commission the project, |

| Sub-Contractor | [SC] | Works for the General Contractor delivering specialist services |

| Vendor/Supplier | [VEN] | Supplies goods, materials and equipment for the project. |

🟩 Level 1 – Tasks, Activities, Roles, and Responsibilities

🟧 Level 1 – 14 Step Matrix

The below table has been written to allow the planning of Level 1 tasks and activities, and we have included a purchasable resource that can be downloaded at the end of this article.

| Level | Task/Activity | O / PM | BO | CxP | DES | GC | VEN |

|---|---|---|---|---|---|---|---|

| L1-01 | Fix and confirm dates of Factory Testing. | I | I | A | I | R | S |

| L1-02 | Create, Develop, and Issue Factory Testing Scripts. | I | I | A | I | R | S |

| L1-03 | Conduct Commissioning Focused Meetings and Workshops, where required. | I | I | A | S | R | S |

| L1-04 | Organize Transportation and Accommodation for Factory Testing. | I | I | A | I | R | S |

| L1-05 | Conduct Factory Acceptance Testing with owner team at factory or remotely. | I | I | A | I | R | S |

| L1-06 | Add any issues to Observation Register and managing to close. | A | I | R | I | S | S |

| L1-07 | Create, Develop, and Issue Factory Testing Reports for all equipment. | I | I | A | I | R | S |

| L1-08 | Obtain and Issue Factory QA/QC documents for record and filing. | I | I | A | I | R | S |

| L1-09 | File and manage Factory Testing information and records within the Project electronic filing system. | I | I | A | I | R | S |

| L1-10 | Install all Red Tags where applicable. | A | I | R | I | S | I |

| L1-11 | Issue Confirmation to Ship Certificate. | I | I | A | I | R | S |

| L1-12 | Ship equipment to site. | I | I | I | I | A | R |

| L1-13 | Provide to Owner, Level Close Out Reports. | I | I | A | I | R | S |

| L1-14 | Sign off Level. | A | I | R | S | S | S |

🚀 Below is an overview of each step noted in the above table.

🟧 L1-01 Fix and Confirm Dates

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should work closely with the commissioning team and vendors to ensure that all factory testing dates and locations are planned and scheduled well ahead of time and in line with the overall project programme.

🟧 L1-02 Issue Factory Testing Scripts

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Factory Testing Scripts, based upon the formats and expected information agreed in Level 0 – Design & Planning Stage, for each piece of equipment being tested, should be issued to the Owners Commissioning Provider for review and approval.

🟧 L1-03 Conduct Commissioning Meetings & Workshops

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Commissioning meetings and workshops should be conducted when planned and required to ensure alignment and coordination among the commissioning team for this stage of work.

The meetings and workshops should aid and facilitate in any discussions relating to not only the factory testing but the overall delivery of the commissioning process across the project.

🟧 L1-04 Arrange Transport and Accommodation/Itinerary

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should ensure that all transport and accommodation are arranged as per the Owners expectations; before booking, an itinerary should be issued to the commissioning team for review and approval.

🚀 Items to consider would be Transport to and from any airport, Transport whilst attending the testing, Flights, Ferry, Taxi, Food, Entertainment, and Food/Beverages etc.

🟧 L1-05 Conduct Factory Testing Activities

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Once all prior tasks and activities have been completed with the commissioning team at the manufacturer’s factory, the testing should commence under the direction of the General Contractor and be monitored by the Owners Commissioning Provider.

🟧 L1-06 Manage Punchlist Register adding Observations

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Support

Any observations or issues noted during the testing should be inputted individually by the General Contractor into the Punch List in the format agreed upon during the Level 0 – Design & Planning Stage. The General Contractor is then responsible for closing them out with the Vendors before the Owners CxP approves.

Any observations that can only be closed out in the factory should be completed before shipping to the site.

🟧 L1-07 Issue Factory Testing Reports

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Factory Testing Reports, based upon the formats and expected information agreed in Level 0 – Design & Planning Stage, for each piece of equipment being tested, should be issued to the Owners Commissioning Provider for review and approval.

🟧 L1-08 Obtain Factory QA/QC Documentation

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Any items of equipment that are not being factory tested under the project requirements should have a full factory QA/QC check conducted before being shipped from the factory.

The QA/QC checklists should then accompany the equipment to site where it will then be filed in the commissioning filing platform/system.

🟧 L1-09 File and Manage Information

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Once all documentation has been completed and approved by the Owner CxP, the General Contractor should ensure it is filed and stored in the location as agreed during the Level 0 – Design & Planning tasks and activities.

🟧 L1-10 Attach Red Tag

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Informed

Once the Owners’ Commissioning Provider has verified that all factory testing, reports, documentation, QA/QC checks have been completed with all punch list items closed, meeting the Level 1 expectations; the General Contractor should place a project ‘Red Tag’ on each component before shipping to site.

![Data Center Level 1-5 [Level 1] Red Tag](https://constructandcommission.com/wp-content/uploads/2021/10/Asset-11L1-Tag-1000w.png)

🟧 L1-11 Issue Confirmation to Ship Certificate

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Where required, the Commissioning Provider shall write and issue a ‘Confirmation to Ship Certificate’ for each component an/or equipment which a ‘Red Tag’ has been attached to.

The General Contractor and Vendors should not ship anything until this is received.

⚠️ Sometimes this step is not required as the ‘Red Tag’ can be sufficient, instead of a Certificate as Proof.

🟧 L1-12 Ship Equipment to Site

Owner: Informed | Building Operator: Informed | Commissioning Provider: Informed | Designer: Informed | General Contractor: Approve | Vendor: Support

Once all the certification is in place, ‘Red Tag/Certificate to Ship’, the General Contractor should instruct the Vendors to ship their Equipment to the site, where the Level 2 – Component Delivery, Installation & Pre-Start-up tasks and activities will commence.

🟧 L1-13 Provide Closeout Report

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should issue a comprehensive ‘close-out report’ as a final summary of the level 1 commissioning process, capturing the results, findings, and outcomes of the various steps.

This report should be provided to the Owners Commissioning Provider for review and acceptance.

🟧 L1-14 Sign-Off Level

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

Once the ‘Closeout Report’ has been received, reviewed, and approved by the Owner CxP, the Level 1 works will be deemed complete and a Certificate Issued.

🟩 Level 2 Tasks and Activities

Click on the above for Level 2 – Component Delivery, Installation & Pre-Start-up Tasks and Activities

⬜ Level 0 to Level 6 Data Center Commissioning Checklist Template [Open / PDF]

To help us expand the site and create more resources, we created the documentation below in [Microsoft Word & Excel] for download.

Click the ‘Buy It Now‘ button to purchase the fully editable copy of the document below, which can be used immediately.

You will direct to our shop page.

Related Articles

STATUS A, B, C & D | What do they mean…

[RFP] CxA REQUEST FOR PROPOSAL | How to Write and Format with Downloads

COMMISSIONING MEETINGS | Explanation and downloadable agenda

LEED Fundamental vs Enhanced Commissioning

BUILDING SYSTEMS MANUAL | How to Write One with Roles

[SOW] CxA SCOPE OF WORKS | How to write and format with downloads

![Data Center Commissioning Checklist [MS Word] & [MS Excel]](https://constructandcommission.com/wp-content/uploads/2023/07/066-Data-Center-Commissioning-Checklist-Shop.webp)