Level 3, managed by the General Contractor, encompasses tasks and activities to ensure that the individual plant, equipment, systems, and components are successfully started up, energized, tested, and operating per the design intent and approved testing scripts/procedures. This stage is crucial to ensure everything is ready for the full Level 4 Functional Testing activities. The primary focus of tasks and activities during Level 3 include:

- Energization & Start-up of Equipment,

- Inputting and Validating Specific Settings,

- General Site Testing,

- Documenting All Level 3 Tasks and Activities,

- Closure of Issues and Observations,

- Readying Systems for Level 4 Functional Testing,

- Attaching the Appropriate Level 3 Tag.

⬛ Additional Resources

To help navigate around the site and provide additional resources, we’ve added plenty of helpful links throughout this article to help you complete your data center commissioning, also below is a list of other articles that we have written that you may find helpful:

- Data Center Commissioning | What is it? including Guideline

- Data Center | 0, 1, 2, 3, 4, 5, 6 Levels of Commissioning [high-level]

- Data Center Redundancy | N, N+1, N+2, 2N & 2N+1 Explained

- Data Center Tiers | 1, 2, 3 & 4 Explained with Downloads

- Level 0 – Data Center Commissioning | Design & Planning

- Level 1 – Data Center Commissioning | Factory Witness Testing

- Level 2 – Data Center Commissioning | Delivery, Installation & Pre-Start Up

- Level 4 – Data Center Commissioning | Functional Testing

- Level 5 – Data Center Commissioning | Integrated Testing

- Level 6 – Data Center Commissioning | Closeout & Turnover

🟩 Sampling Rate

When it comes to witnessing and validation onsite, many Owners will utilize a ‘Sampling Rate‘ to make the process of evaluating the facilities systems, components, and equipment more efficient and manageable, as it’s often impractical or unnecessary to examine every single data point or component across a project.

By witnessing and validating ‘Samples’, the Owners Commissioning Provider can confidently conclude and advise them on their entire facility and its systems.

During the ‘Level 3’ tasks and activities, we refer to this sampling as ‘First Of Kind [FOK]’ Inspections or Testing. This means the CxP will randomly select 1No. Piece of equipment, component, or system from a batch for witnessing and verification.

If the witnessing activities ‘Pass’, all units and parts of the batch will also be determined to ‘Pass’.

🚀 The General Contractor should ensure that no matter the verification requirements of the Owners Commissioning Consultant, they complete 100% testing of all plant, equipment, components, and systems.

🟧 Sampling Rate to Use

For the Level 3 works, the following would be pretty common to see on a standard Data Center Project:

🟨 Documentation Sampling

⚠️ Note: the documentation sampling rates are not to be confused with items like ‘Single Point of Failure’ or ‘Discrimination Study Reviews‘, where 100% would be expected.

| Type | Sampling Rate |

|---|---|

| Design Documents | 25% |

| Construction Documents | 25% |

| Handover Documents | 100% |

🟨 Onsite Sampling

| Sampling Rate | Notes |

|---|---|

| Critical Systems & Components [FIRST OF KIND] | Inspect, witness and Validate 1No. of each model of Equipment, Components and Systems. Covers: Anything that affects the operations of the data halls and critical spaces, either via plant, equipment, components, and systems directly installed within the halls, or plant, equipment, components, and systems housed outside of the data halls and critical spaces but serves them. |

| Non-Critical Systems & Components [20%] | Inspect, witness and Validate 20% of Equipment, Components and Systems. Covers: Non-Critical Systems and Components would include plant, equipment, components, and systems individually serving toilets, cupboards, external corridors, office, meeting rooms etc. |

🟩 Using the RASCI Matrix

For the roles and responsibilities, we will utilize the RASCI format, which helps with defining and communicating the required roles and responsibilities within the process and will dictate, via a structured framework, who is Responsible, Accountable, Supportive, Consulted, and Informed for each task, activity, or decision.

Using the matrix will enhance management and teamwork, promoting clarity, reducing confusion, and fostering effective communication.

| Responsible | [R] | This is the person that is responsible for doing the work ensuring the activities are completed by the relevant team members, they can also provide comments as well. |

| Approve | [A] | This person comments, approves and signs off and owns the activity. |

| Supportive | [S] | Persons who will provide support to the Responsible party, aiding in completion of the task. |

| Consulted | [C] | Opinion sought, where required. |

| Informed | [I] | This person is informed when a decision is made, or an activity is performed. They may be required to act because of the outcome. |

🟩 Roles of Team Members

The following participants will be involved in the delivery of the Level 3 – Commissioning Tasks and Activities:

| Owner | [O] | The owner is the person who will own/occupy or run the facility once it is complete; they have the final say in the overall expectations of the project and finance it. |

| Building Operator | [BO] | The company and people responsible for operating the facility once handed over. |

| Project Manager | [PM] | The project manager, employed to represent the owner, running and managing the overall project and programme. [where owner is not fully involved in the day to day running of the project]. |

| Commissioning Provider | [CxP] | The consultant employed by the Owner to ensure that the project is verified to meet their expectations, |

| Designer | [DES] | Responsible for taking the Owner's expectations/requirements and creating a design that works in line with them, |

| General Contractor | [GC] | The company employed to construct, build and commission the project, |

| Sub-Contractor | [SC] | Works for the General Contractor delivering specialist services |

| Vendor/Supplier | [VEN] | Supplies goods, materials and equipment for the project. |

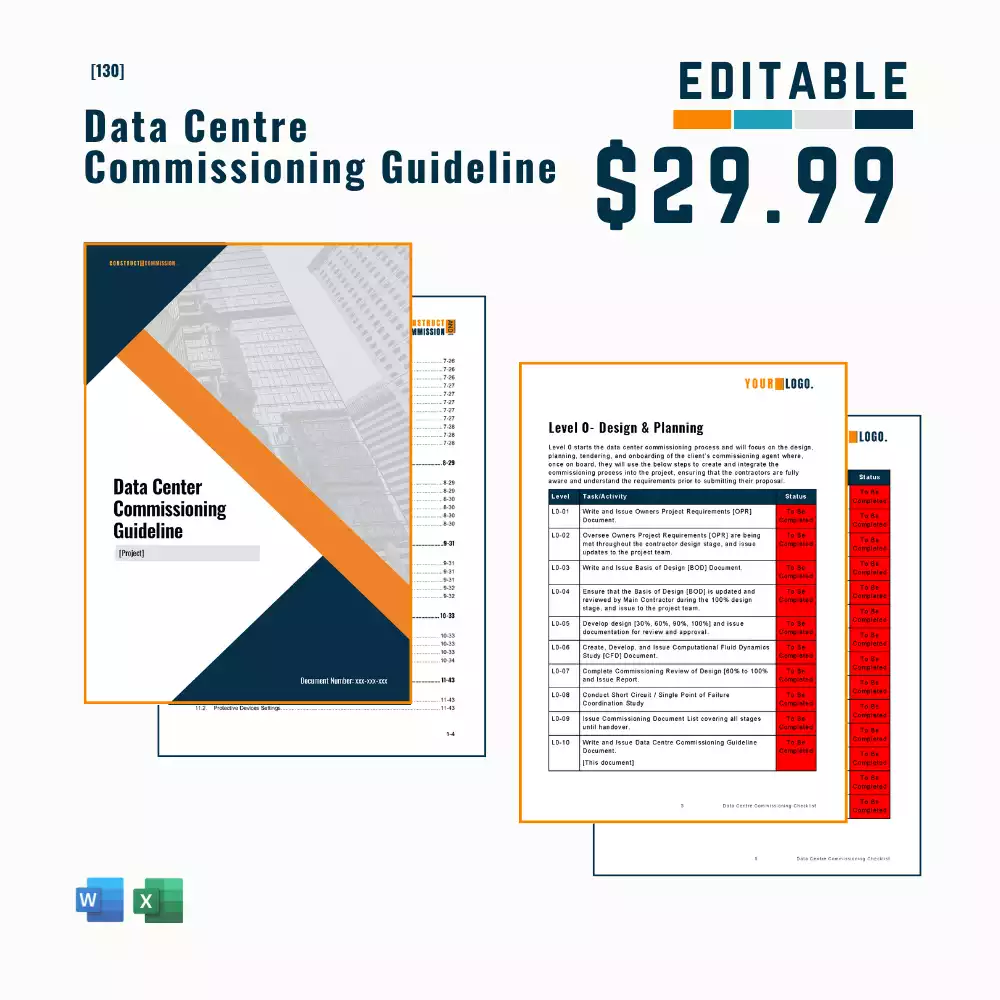

- Use Straight Away

- Insert in Tender Documents

- Industry Wide Process from Level 0 to Level 6

- Detailed Responsibility and Roles

- Includes Commissioning Checklist

Aimed at anyone who needs a detailed delivery plan and checklist for deploying Commissioning within a Data Center Project, this document is formatted in Microsoft Word/Excel and written so that it can be deployed quickly and easily with minimal updating to suit your specific needs.

[Once through to the shop there is a sample of the document to view]

- Easy

- Quick

- High Level

- Tracker

Here is our open copy [MS Word] & [MS Excel] of the Data Center Commissioning Checklist, for making life a little easier...

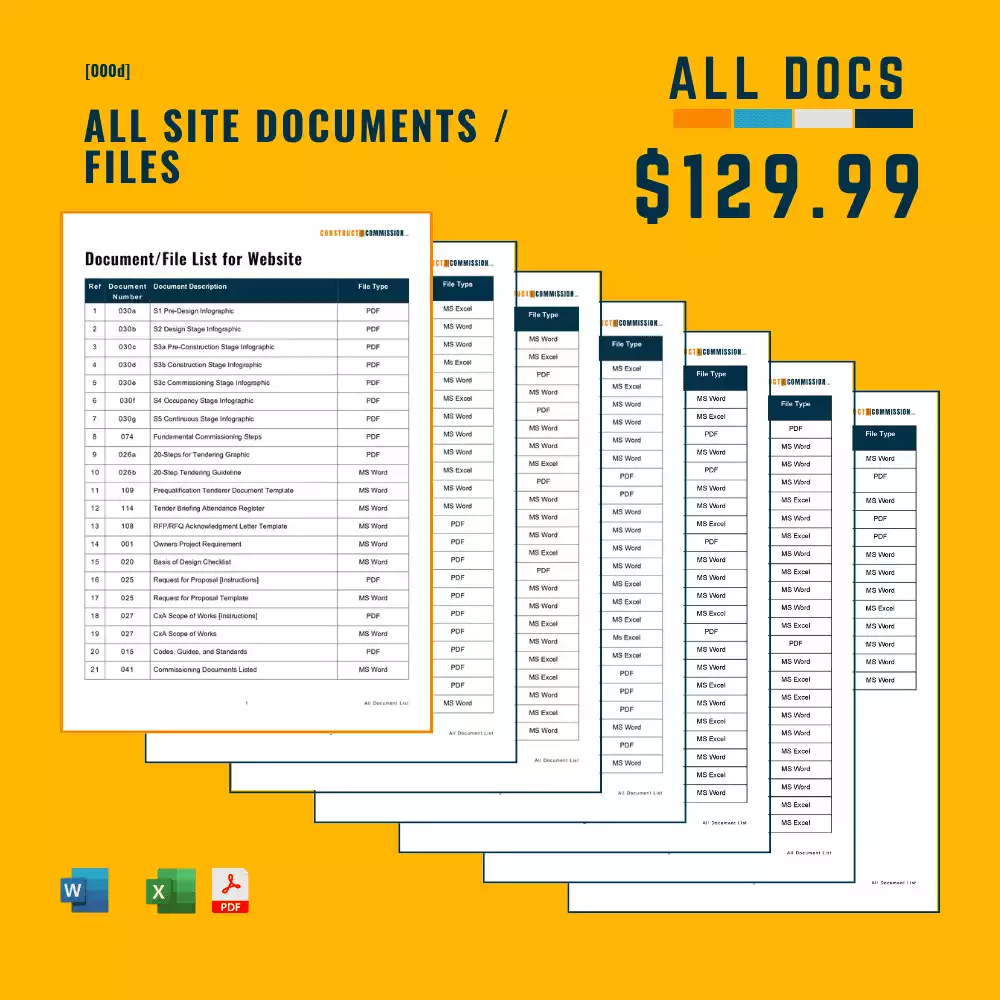

- 126No. Documents

- Use Straight Away

- Amazing Value

We have been asked several times to create a complete document package covering everything we have uploaded to the site.

So it's taken some time, but here it is....126No. Documents for you to download in Microsoft Word, Microsoft Excel & PDF Formats.

CLICK THE BUY HERE TO SEE/DOWNLOAD A FULL LIST OF DOCUMENTS INCLUDED...

🟩 Level 3 – Tasks, Activities, Roles, and Responsibilities

🟧 Level 3 – 21 Step Matrix

The below table has been written to allow the planning of Level 3 tasks and activities, and we have included a purchasable resource that can be downloaded at the end of this article.

🚀 Many tasks and activities will be similar to the Level 2 works, just continuing from those tasks and activities.

| Level | Task/Activity | O / PM | BO | CXP | DES | GC | VEN |

|---|---|---|---|---|---|---|---|

| L3-01 | Write and Issue Scripts/Start-up Plans that will be used to facilitate the start-up and testing works. | I | I | A | I | R | S |

| L3-02 | Write and Issue Work Permits as noted in Level 0 that will be used to facilitate the start-up and functional testing works. | A | C | I | I | R | S |

| L3-03 | Install Temporary Equipment and Instruments to facilitate the testing and Level 4 Works in line with the Load Bank & Equipment Plan. | I | I | A | S | R | S |

| L3-04 | Ensure BMS and Control Logics are ready and available. [Point to Graphic / Sequence of Operation] | I | I | A | S | R | S |

| L3-05 | Ensure Control Room and equipment is ready and available, for testing to commence. | I | I | A | I | R | S |

| L3-06 | Plan and Manage Energization, Site Testing and Acceptance of plant, equipment, and materials in line with approved procedures, scripts, and programme. | I | S | A | S | R | S |

| L3-07 | Conduct any First of Kind [FOK] Testing if noted in the project process with the Owner’s Commissioning Consultant. | I | S | A | I | R | S |

| L3-08 | Update Commissioning Tracking to reflect actual status and progress. [Manually or as per Commissioning Electronic Platform] | I | I | A | I | R | S |

| L3-09 | Manage the Overall Programme for the Commissioning Tasks and Activities. | I | I | A | I | R | S |

| L3-10 | Add any issues to Observation Register and managing to close. | I | I | A | I | R | S |

| L3-11 | File and manage documentation and records within the Project electronic filing system. | I | I | A | I | R | S |

| L3-12 | Issue regular 2 Week Look Ahead Schedules for Commissioning Team Resource Planning. | I | I | A | I | R | S |

| L3-13 | Conduct Daily Morning Coordination Workshop. | I | I | A | I | R | S |

| L3-14 | Provide Daily Commissioning Updates. | I | I | A | I | R | S |

| L3-15 | Conduct Commissioning Focused Weekly Meetings and Workshops. | I | S | A | I | R | S |

| L3-16 | Provide to CxP, Commissioning Focused Reports. [Monthly / Weekly] | I | I | A | I | R | S |

| L3-17 | Provide to Owner, Commissioning Focused Reports. [Monthly / Weekly] | A | I | R | I | S | S |

| L3-18 | Issue Operation and Maintenance Manuals. | C | C | A | C | R | S |

| L3-19 | Complete Clean of Data Halls and critical areas. | A | C | S | I | R | S |

| L3-20 | Install all Green Tags where applicable. | I | I | A | I | R | S |

| L3-21 | Provide to Owner, Level Close Out Reports. | I | I | A | I | R | S |

| L3-22 | Sign off Level. | A | I | R | S | S | S |

🚀 Below is an overview of each step noted in the above table.

🟧 L3-01 Write and Issue Scripts/Start-up Plans

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The Level 3 Scripts and Start-up Plans, based upon the formats and expected information agreed in Level 0 – Design & Planning Stage, for each piece of equipment, component, and system being energized and started up, should be issued to the Owners Commissioning Provider for review and approval.

🟧 L3-02 Write and Issue Work Permits

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Informed | Designer: Informed | General Contractor: Responsible | Vendor: Support

‘Work Permits’ should be written and issued by the General Contractor to the project team where authorization is required to conduct and complete any specific tasks and activities. They will generally cover multiple types of works, for example:

- General Power On [Lock Out/Tag Out],

- Energization of Equipment,

- Integration of New Chilled Water Systems with Existing,

- Integration of New Equipment with Existing Systems.

The format of these permits should have already been discussed and agreed upon during the Level 0 – Design & Planning Stage.

🟧 L3-03 Install Temporary Equipment and Instruments for Level 4

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

The General Contractor should ensure that all temporary equipment, instruments, and components required for the Level 4 works are installed during the Level 3 works in line with the Owner CxP provided ‘Load Bank and Equipment Plan’.

This ensures that any issues are resolved, and everything is ready as soon as the overall Level 3 works are completed.

🟧 L3-04 Ensure BMS and Control Logics are Ready

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

One of the most common challenges affecting the overall commissioning program is the Building Management Systems [BMS] readiness, their associated Points, and System Control Logics [sequence of operations].

The BMS and Control Systems are central to ensuring that the Level 3 works can be completed successfully, so during this stage, there should be a focus on ensuring that they are ready.

🟧 L3-05 Confirm Control Room Ready

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

To ensure that all data and information are captured from the system’s start-up and testing, the ‘Control Room’ must be ready with a head end, screens, tables, etc.

🟧 L3-06 Plan & Manage Energization and Testing

Owner: Informed | Building Operator: Support | Commissioning Provider: Approve | Designer: Support | General Contractor: Responsible | Vendor: Support

The General Contractor oversees the Level 3 works, focusing on the planning, energization, and testing activities, with all works aligning with the approved Level 3 Scripts and Start-up Plans.

🟧 L3-07 Conduct First Of Kind [FOK] Inspections

Owner: Informed | Building Operator: Support | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Once the General Contractor has completed their own testing and verifications, they shall invite the CxP to complete a ‘First of Kind Inspection.’

🚀 see the Sampling Section at the beginning of this article for more information on FOK.

When invited, the CxP will randomly select a piece of equipment, component, and or system from each type that has been installed and conduct the same inspections to ensure it meets the requirements.

🟧 L3-08 Maintain Commissioning Progress Tracking

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Throughout the Level 3 tasks and activities, the General Contractor should consistently update the Commissioning Progress Tracking Schedules.

🟧 L3-09 Manage and Update Cx Programme

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Throughout the Level 3 tasks and activities, the General Contractor should ensure the Commissioning Programme is consistently updated.

🟧 L3-10 Manage Punch Lists and Closure of Issues

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Any observations or issues noted during the works should be inputted individually by the General Contractor into the Punch List in the format agreed upon during the Level 0 – Design & Planning Stage. The General Contractor is responsible for closing them out with the Vendors before the Owners CxP approves.

All observations should be closed before the Level 4 tasks and activities commence.

🟧 L3-11 File and Manage Information

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Once all documentation for the Level 3 works has been completed and approved by the Owner CxP, the General Contractor should ensure it is filed and stored in the location as agreed during the Level 0 – Design & Planning tasks and activities.

🟧 L3-12 Maintain 2-Week Look-Ahead Schedules

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Based on the format agreed upon during the Level 0 – Design & Planning Stage, the General Contractor should issue [weekly] a 2-week look ahead schedule that fully represents the progress of the commissioning works and future activities.

🟧 L3-13 Conduct Daily Morning Coordination Workshops

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Morning Coordination Workshops should be held daily, led by the General Contractor, to provide a forum where the commissioning team [Owner, Building Operator, CxP, Designer, General Contractor, Vendors, and Subcontractors] can be aligned, helping to keep commissioning efforts moving forward proactively.

These workshops should be used to review the status of commissioning activities, with the key objectives being to coordinate that day’s tests and tasks, address any issues or roadblocks, update commissioning checklists and documentation, review action items, and discuss and prepare for the next day’s activities.

🟧 L3-14 Issue Daily Commissioning Updates

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

As the Owners Commissioning Provider is not usually overseeing all commissioning activities, the General Contractor should provide a simple update each day on the progress made and any problems or issues encountered. The format of this report should be based upon the agreement during the Level 0 – Design & Planning Stage.

This ‘Daily Report‘ should be issued to the CxP for information.

🟧 L3-15 Conduct Commissioning Meetings & Workshops

Owner: Informed | Building Operator: Support | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Commissioning meetings and workshops will be conducted throughout the Level 3 stage to ensure alignment and coordination among the members of the project commissioning team [Owner, Building Operator, CxP, Designer, General Contractor, and Vendors/Subcontractors].

These meetings & workshops should help facilitate discussions around the commissioning processes, documentation, schedules, observations, Level 3 works, and the future tasks and activities that need to be addressed and planned, such as integrated systems testing, training, manuals, and handover procedures.

🟧 L3-16 Issue CxP Commissioning Reports

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should issue weekly/monthly reports to the Owners Commissioning Provider based upon the formats and expected information agreed upon in the Level 0 – Design & Planning Stage.

🟧 L3-17 Issue Owner Commissioning Reports

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Informed | General Contractor: Support | Vendor: Support

Once received from the General Contractor in the previous step, the Commissioning Provider should issue the Owner a consolidation of the General Contractor’s report and theirs.

🟧 L3-18 Issue Draft Operating & Maintenance Manuals

Owner: Consulted | Building Operator: Consulted | Commissioning Provider: Approve | Designer: Consulted | General Contractor: Responsible | Vendor: Support

Ensure that the facility Operating and Maintenance Manuals [O&M] are issued as ‘Draft’ for the comment of the Owners Team.

The manuals should be in the format agreed upon during the Level 0 – Design & Planning Stage.

⚠️ Note: these would only be for the Building Services Systems.

🟧 L3-19 Deep Clean Data Halls & Critical Spaces

Owner: Approve | Building Operator: Consulted | Commissioning Provider: Support | Designer: Informed | General Contractor: Responsible | Vendor: Support

Deep cleaning of the critical spaces will usually be part of the project requirements to ensure no dust, debris, or metal filings/swarf could impact the operation of the live computer equipment. The work will usually be completed by a specialist cleaning contractor and managed by the General Contractor.

This ensures it is completed before moving to the Levels 4 & 5 activities, where the Owners Commissioning Provider will take over and command the data center commissioning process.

At the end of the works, a certificate will be provided that should be included within the commissioning documentation to prove that the cleanliness meets the specification.

⚠️ Note: Depending on the agreement, this work could be completed during the Level 6 Handover Works.

🟧 L3-20 Attach Green Tag

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

Once the Owners’ Commissioning Provider has verified that all Level 3 tasks and activities have been completed with all punch list items closed for each piece of equipment, component, or system, meeting the Level 3 expectations, the General Contractor should attach the required project ‘Green Tag.’

![Data Center Level 1-5 [Level 3] Tag](https://constructandcommission.com/wp-content/uploads/2021/10/L3-Tag-1000w.png)

🟧 L3-02 Provide Closeout Report

Owner: Informed | Building Operator: Informed | Commissioning Provider: Approve | Designer: Informed | General Contractor: Responsible | Vendor: Support

The General Contractor should issue a comprehensive ‘close-out report’ as a final summary of the Level 3 commissioning process, capturing the results, findings, and outcomes of the various steps.

This report should be provided to the Owners Commissioning Provider for review and acceptance.

🟧 L3-22 Sign-Off Level

Owner: Approve | Building Operator: Informed | Commissioning Provider: Responsible | Designer: Support | General Contractor: Support | Vendor: Support

Once the ‘Closeout Report’ has been received, reviewed, and approved by the Owner CxP, the Level 3 works will be deemed complete and a Certificate Issued.

🟩 Level 4 Tasks and Activities

Click on the above for Level 4 – Functional Testing Tasks and Activities.

⬜ Level 0 to Level 6 Data Center Commissioning Checklist Template [Open / PDF / Excel]

To help us expand the site and create more resources, we created the documentation below in [Microsoft Word & Excel] for download.

Click the ‘Buy It Here‘ button to purchase the fully editable copy of the document below, which can be used immediately.

You will direct to our shop page.

⬛ Related Articles

ASHRAE | Guideline 1.1 – Is it worth $87…

COMMISSIONING CHECKLISTS | The 3 Types Explained and Templates Listed

TENDER BRIEFING SESSION | How to Conduct with downloads

ASHRAE | Commissioning Stakeholders Guide – Brilliant, Love it…

COMMISSIONING PLAN | What, Why, When, How with Template

COMMISSIONING MEETINGS | Explanation and downloadable agenda

![Data Center Commissioning Checklist [MS Word] & [MS Excel]](https://constructandcommission.com/wp-content/uploads/2023/07/066-Data-Center-Commissioning-Checklist-Shop.webp)