A CRAH unit is a critical piece of close control cooling equipment, consisting of filters, fans, coils, that is connected to chilled water/cooling water pipework to precisely manage and control the temperature and humidity of a space within specified design tolerances. They can usually be found within a mission-critical space, data center, data hall, IT, or UPS Room.

What does ‘CRAH Unit’ stand for?

The full form of CRAH Unit is – Computer Room Air Handling Unit.

![[079] CRAH Units Location and Rooms](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Units-Location-and-Rooms.png)

Locations and Rooms where CRAH Units are found

Similar to CRAC Units, CRAH’s can be found in multiple locations, commonly:

- Data Centers / Mission Critical Spaces

- Data Halls

- CRAH Corridors

- IT Rooms

- Electrical Switch Rooms

- UPS [uninteruptable power supply] Rooms

![[079] CRAH Unit Design Configurations](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Unit-Design-Configurations.png)

Different CRAH Unit Design and Installation Configurations

Depending upon the layout and configuration of the room where the CRAH Units are installed/located, a couple of configurations will be seen. We have listed and detailed some of these below:

- Down Flow Supply

- Up Flow Supply

- Frontal Flow Supply

- Under Floor Supply

CRAH Down flow configuration

A ‘Down flow’ unit draws air from the space that is to be cooled, through the top of the CRAH Unit. After entering the unit, it is drawn downwards through the cooling coil where it is conditioned prior to being blown back into the space via the lower frontal part of the unit.

[This configuration is quite common in Data Halls for CRAH Units where a ‘fan wall is used’]

![[079] CRAH Unit Down Flow Diagram](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Unit-Down-Flow-Diagram.png)

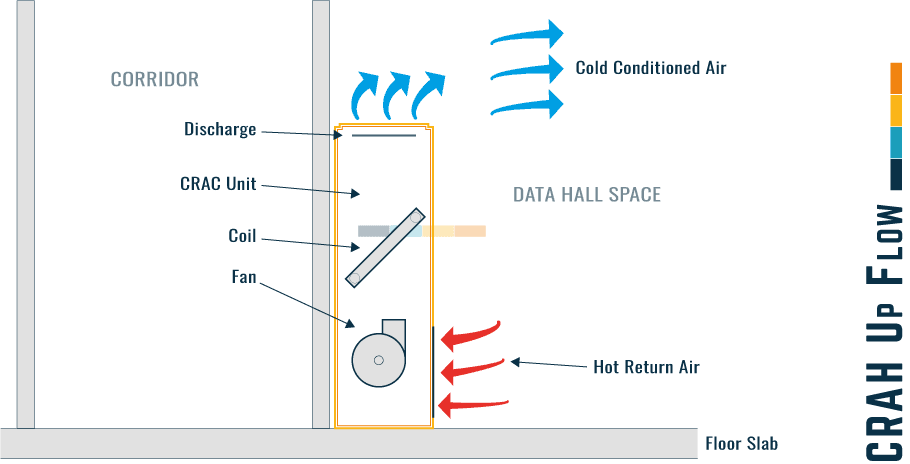

CRAH Up flow configuration

A ‘Up flow’ unit draws air from the space that is to be cooled, through the lower frontal section of the CRAH Unit. After entering the unit, it is drawn upwards through the cooling coil where it is conditioned prior to being blown back into the space via the upper frontal part of the unit.

[This configuration is quite common in Electrical Rooms, IT Rooms, and UPS Rooms.]

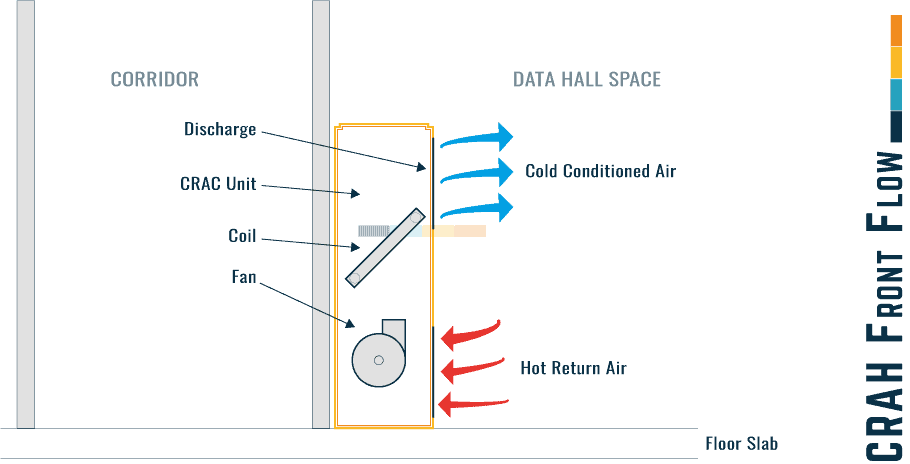

CRAH Frontal flow configuration

A ‘Frontal Flow’ unit draws the hot air from the space, through the lower frontal section of the CRAH Unit. After entering the unit, it is drawn upwards through the cooling coil where it is conditioned prior to being blown back into the space via the upper frontal part of the unit.

This is common in Electrical Switch / UPS / IT Rooms, like with the CRAC Units, ducting may be connected to direct the air better as usually there is other equipment that can hinder the airflow.

[this can be reversed for a frontal flow from the lower section of the unit, as per a downflow configuration].

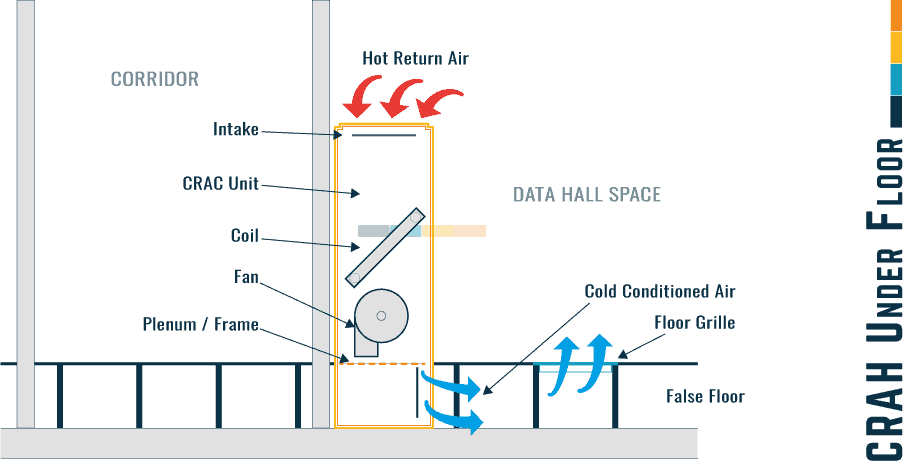

CRAH Unit Under floor supply

The configuration is very similar to the ‘downflow’ unit, with the hot air being drawn into the unit through the top and then through the cooling coil.

The difference is that the CRAH unit will be mounted on a frame, that can also be used as a plenum, installed within the floor to allow conditioned air to pass through to be discharged into the void.

The conditioned air in the floor will pass into the space to be conditioned by using floor grilles, positioned in the locations needed, usually near/in front of the racks.

![[079] CRAH Unit Cooling Medium Type](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Unit-Cooling-Medium-Type.png)

Cooling medium used

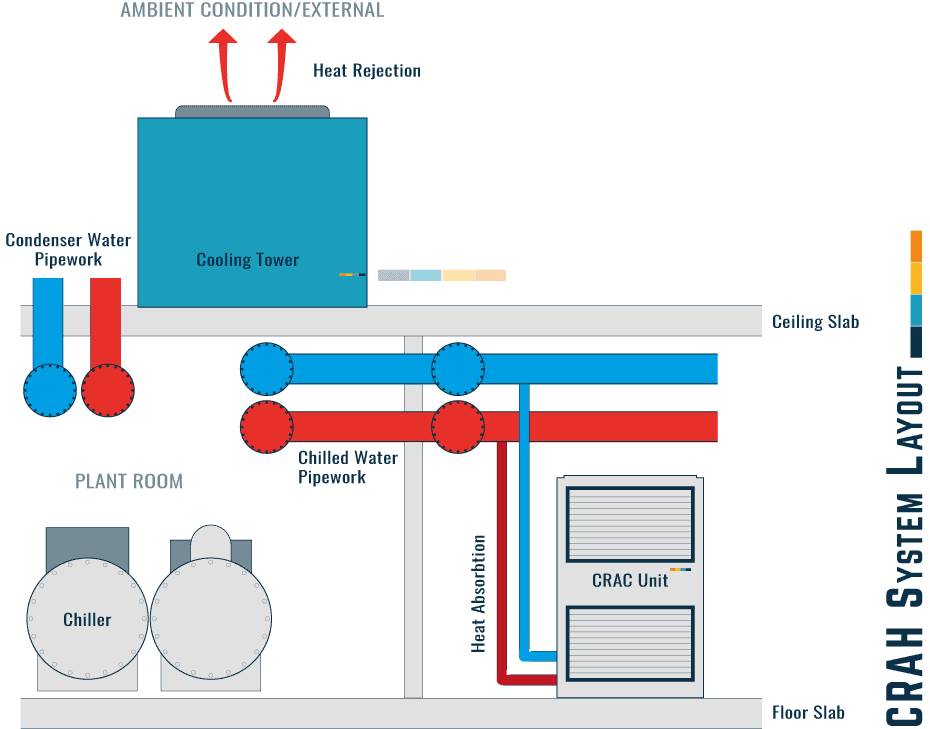

A CRAH Unit, computer room air handling unit generally will use chilled water to manage the cooling process.

The pipework from the CRAH unit will usually be connected to a ‘ring main’ where the common pipework for the space if using multiple CRAH Units, will route through to a plant room area where an Air Cooled or Water Cooled Chiller with Cooling Tower will remove and reject the heat creating the cooling process.

[A CRAC unit (computer room air conditioning unit), uses a Refrigerant [usually R410A] and an external condenser unit.]

See our article 'CRAC UNITS | What are they' for more detailed information on that type of equipment.

![[079] CRAH Unit Main Components](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Unit-Main-Components.png)

What are the main components of a CRAH Unit?

The main component of a CRAH unit/system consists of:

- Unit Frame

- Panels [sides, bottom and top]

- Sound attenuation [sound attenuation/absorbing foam/fiber glass insulation sandwiched between the panel skin]

- Access doors to various compartments

- Inspection windows

- Base frame

- Supply air plenum

- Return air plenum

- Filters

- Fan section

- Motorized dampers [inlet/outlet]

- Energy efficient fans

- Fan guards

- Variable speed drive

- Motors

- Vibration isolators

- Cooling coil [chilled water]

- Condensate drip pan

- Condensate pipework

- Condensate pump [if required]

- Reheat coil [if required]

- Humidifier [if required]

- Control valves

- Isolation Valves

- Strainer

- Pressure Gauges

- Temperature Gauges

- Commissioning Stations/Automatic Balancing Valves

- Chilled Water Pipework

- Control panel

- Control wiring

- Network switch [if using multiple units]

CRAH vs AHU: If we took a CRAH Unit and laid it horizontally a lot of the layout and components would have a similarity to an Air Handling Unit or even the more basic Fan Coil Unit, similar to the CRAC Unit.

If you are wondering what the difference is between a CRAC Unit and CRAH Unit see our article 'CRAC Unit vs CRAH Unit | What's the difference'

![[079] CRAH Unit How do They Work](https://constructandcommission.com/wp-content/uploads/2021/12/079-CRAH-Unit-How-do-They-Work.png)

How does a CRAH Unit Work?

A computer room air handler [CRAH] Unit works by recirculating air from a space needing to be conditioned by using its fans to draw the hot air in and then passing it over a cooling coil where it is cooled before being blown back into the space fully conditioned and cooled.

The cooling process of the coil uses chilled water, which is delivered by the central plant [chiller, pumps, cooling towers] to produce the cooling capacity necessary.

The conditioned chilled water absorbs and transfers the heat from the hot air passing over the cooling coil and removes it to the chillers for reconditioning.

[Below is a simple CRAH Unit Piping Diagram – with Cooling Tower]

The heat is then taken via the refrigerant pipework and refrigerant as a gas through the compressor where it will be compressed before passing through the external condenser unit which will use fans to pass ambient air across the coil removing the heat from the refrigerant prior to passing through the expansion valve and the cooling coil.

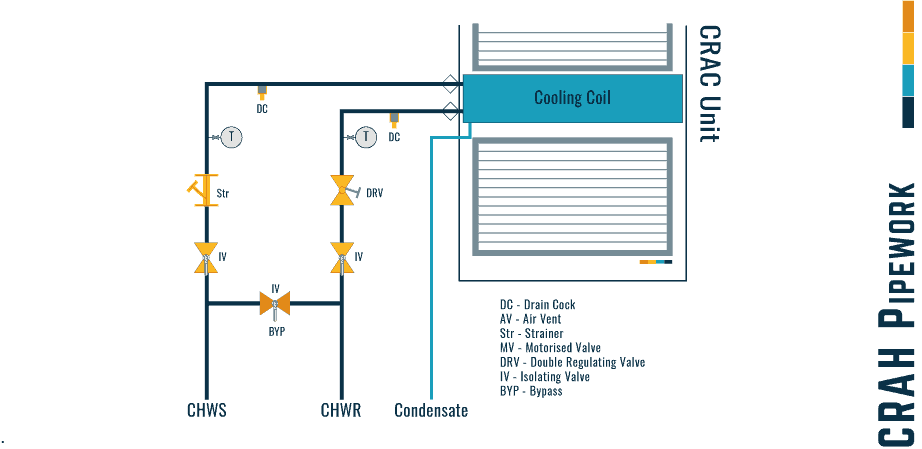

CRAH Unit Pipework Diagram

Below shows a ‘typical’ diagram for a CRAH Pipework and condensate.

CRAH Unit Manufacturers

There are lots and lots of manufacturers of CRAH Units worldwide, the main ones that we have come across are similar to the CRAC Units:

- Airedale

- Stulz

- Trane

- Vertiv / Liebert [Emerson]

- York

CRAH Unit Pre-Functional Checklist

To cover what is needed on site for the Pre-Functional Checks prior to commissioning see our article 'CRAH UNIT | Pre-Functional Checklist'

⬛ Related Articles

LEVEL 2 – DATA CENTER Cx | Delivery, Installation & Pre-Start Up

LEVEL 3 – DATA CENTER Cx | Systems Start-Up

LEVEL 1 – DATA CENTER Cx | Factory Witness Testing

LEVEL 4 – DATA CENTER Cx | Functional Testing

CRAH UNIT | Pre-Functional CheckList

LEVEL 5 – DATA CENTER Cx | Integrated Testing [IST]