The types of Cooling Towers and Ponds come in many forms, sizes, and prices, but all have the same purpose, to act as a heat rejecting device to transfer, remove and eject heat from an industrial process or a building air conditioning process before recirculating the cooler water back into the system.

They are generally called ‘evaporative coolers,’ and below, we provide a high-level description of the following:

- Ponds

- Crossflow

- Counter flow

- Induced Draft

- Forced Drat

- Natural Draft

- Hyperbolic

Types of Ponds

Ponds are generally covered by the simple lake type ‘cooling pond’ or a ‘spray’ type pond.

What are Cooling Ponds?

Cooling ponds are usually big bodies of water that would appear more like a lake or large pond. They traditionally are used to process and cool the warm water created by an industrial process such as:

- Power plant operations [nuclear plants, coal-fired plant]

- Refineries

- Mills [paper, steel etc] &

- Chemical plants

- Food processing plants

The cooling process is achieved via warm/hot water from the process being pumped into the pond, which then will be allowed to flow naturally to allow cooling via radiation, evaporation, and conduction before being recirculated back into the cooling system via the system pumps.

For an example, refer to Lake Anna, where Dominion Energy operates the North Anna Nuclear Generating Station, providing power for 450,000 homes.

Due to the heat transfer inefficiencies by using this method, a large water surface is required.

Advantages of Cooling Ponds

Oleson and Boyle note the following advantages:

- Construction costs are quite low, where land and soil conditions allow

- They can serve as a settling pond for any suspended solids produced by the water being cooled

- Limited cooling water make-up required, can be replenished by rain

Disadvantages of Cooling Ponds

They also note the following disadvantages:

- Large area of land needed

- Low soil permeability

- Issues if there is ice

- Can cause fog

How do Spray Ponds Work?

Using no mechanical fans, spray ponds are an alternative design that utilizes nozzles mounted a few feet [1.5m to 2.0m] from the water surface of the pond/basin that atomizes the warm water received from a process to increase its surface area and contact time with the surrounding air.

This boosts the efficiency and available cooling performance of the equipment.

The warm water enters via the nozzles and is recirculated back to the system by pipework connected at a low level to the pond basin.

Like with the cooling pond, they are commonly used to process and cool the warm water created by an industrial process such as:

- Power plant operations [nuclear plants, coal-fired plant]

- Refineries

- Mills [paper, steel etc] &

- Chemical plant

Advantages of Spray Ponds

The following advantages can be gained by using the Spray type tower.:

- Less land area required vs a cooling pond

- Can be used for commercial applications and not just industrial

- Lower water consumption [due to the reduced surface area]

Disadvantages of Spray Ponds

Alternatively, the disadvantages are:

- Drift of water and droplets

- Limited other uses such as with the cooling pond [fishing, swimming, canoeing etc]

- Additional maintenance, especially with the nozzles and potential blockages

- Unreliable performance from fouling of nozzles

Types of Cooling Towers

Cooling towers can be broken down into 2 main types of designs and 2 sub designs:

| Mechanical Draft Tower | Fans used | Induced Draft | Counter Flow | Cross Flow |

| Fans Used | Forced Flow | Counter Flow | ||

| Natural Draft Tower | No fans used | Natural Draft | Counter Flow | Cross Flow |

Cooling Tower Components:

If you would like to learn more on the different components of the cooling towers below see our article ‘37 Cooling Tower Components‘

Mechanical Draught Towers:

Mechanical draft towers will incorporate a mechanical fan to create the airflow needed to ensure evaporative cooling takes place, removing the unwanted heat, in turn, lowering the temperature of the water before being pumped back into the system.

Designers of building services systems will generally use 1 of 3 types within their designs:

- Cross flow – Induced draft

- Counter flow – Induced draft

- Counter flow – Forced draft

Counter flow vs Cross flow Cooling Towers

The differences are straightforward between cross flow and counter flow cooling towers and can be summarized as follows:

- Cross flow – The cooling tower fill pack is installed vertically at a slight angle near the outside walls, allowing the airflow to travel horizontally across/through it, whilst the water, to be cooled, drops downwards [cross flow]. See diagram below.

- Counter flow – The cooling tower fill pack is installed horizontally half way up the tower, allowing the airflow to travel vertically through it whilst the water, to be cooled, drops downwards [counter flow]. See diagram below.

What are the advantages of a Cross flow cooling tower vs Counter flow?

- A Counter flow tower, upto about 3.5MW requires less footprint than a similar Crossflow type.

- Crossflow has better access for maintenance that the Counter flow

- Cross flow is easier to maintain than Counter flow

- In a Crossflow tower, due to using a hot water basin at the top of the tower to feed the warm water into the ‘fill’, the pressure requirements are usually less than for a similar installation using a cross flow tower that has pressurized nozzles.

- Crossflow tower has better efficiency and control of cooling at lower loads.

What is an Induced Draft Cooling Tower?

An induced draft tower is constructed with a tall stainless steel casing [square or round], with axial fans located at the top, pulling air into the tower that enters via the side.

The external casing of the tower, where the entering air is drawn through, will be packed with a material [wood slats or plastic], usually referred to as ‘Fill,’ specifically designed to allow the warm water to flow down and the air through. This is referred to as ‘Cross Flow.’

The reason for the material is to increase the ‘wetted’ area of the tower allowing for more evaporative cooling to occur.

The fill can also be installed horizontally, providing a ‘Counter Flow’ type design as described above.

Once the air has passed through the material, the warmer air will then be pulled up through the fan, mounted at the top, and released into the atmosphere, with the rejected air being warmer and more humid, which is what can be seen as a ‘plume’ sometimes during cooler months from the top of the tower.

The water will be introduced at the top of the tower via pipework from the condenser system and allowed to flow freely through the fill material under gravity, allowing an even water distribution.

There will be a catchment basin at the bottom of the tower to collect the water, ready for pumping back into the condenser system.

Advantages of an Induced Cooling Tower:

- Cost effective to purchase and efficient to run

- Simple to manufacture and transport

- Site installation is not complex and can be installed in various locations

- Simple to commission and setup

- Air flow has even distribution.

- Leakage in the tower will only introduce ambient air, due to the suction of the fan arrangement.

- Humid air and ‘spray’ is ejected from the tower vertically at velocity, reducing short cycling of air.

- Reduction in the impact wind pressure will have on the equipment operation

- Relatively low noise

- Low maintenance cost

- Easy to maintain as not many moving parts, especially if the options are purchased and installed such as the lifting equipment to remove the fans.

- Easy to remove and replace as are usually a modular construction

Disadvantages of an Induced Cooling Tower:

There are a lot more advantages than disadvantages…

- The moving parts are directly in a humid air stream, this will possibly accelerate the corrosion of those parts if not purchased with the correct protection and maintained inline with the manufacturers instructions.

- Vibration can be an issue if the fans are not set up properly, resulting in accelerated failure of parts and materials

- During the design stage, if the maintenance requirements for gaining access to and maintaining/replacing the high level parts [fans, motors] have not been considered or addressed then will cause potential issues.

What is an Forced Draft Cooling Tower?

A forced draft cooling tower operates using centrifugal fans to push ‘force’ ambient air through the tower at a low level, helping to remove the heat generated within a production/system process.

The warm air then flows up through the tower, picking up heat from the water flowing in the opposite direction through the ‘fill’ before being ejected through the top of the tower.

Force draft towers generally will only use the counterflow design, as can be seen below.

What is the advantage of forced draft cooling tower?

- Easy to replace and swap like for like

- Able to overcome static pressure on ducting if used to route the rejected heat from the tower

- Moving parts are not within the hot humid air stream, helping prolong the life of the equipment

- Maintenance of the fans are generally easier for removing as are installed at low level within the tower.

- Lower noise level [for centrifugal fans, axial fans usually higher]

What are the disadvantages of a forced draft cooling tower?

- A forced draft cooling tower consumes more power/energy than an Induced type tower.

- Can cause issues with recirculation of hot air back into the tower as the expelled air ‘drifts’ away and not pushed, like with an induced tower.

- Only can have counter flow meaning maintenance of the internal parts of the tower is more restricted.

Natural Draft Cooling Towers

These cover anything that does not incorporate a mechanical fan to create the airflow needed to ensure evaporative cooling takes place and removes the unwanted heat from the water.

A great example of a natural draft cooling tower is the Hyperbolic type.

Hyperbolic [Hyperboloid] Cooling Towers

After the shape Hyperboloid, a hyperbolic cooling tower is probably the most recognizable shape and type of tower that we see near power stations, but are also used in similar industries to the cooling ponds/spray pond type cooling systems above.

Why is a Cooling Tower Hyperbolic?

The cooling tower is designed and constructed as a hyperboloid shape for a few reasons:

- Ease of design / construction due to limited types of materials used

- To manage costs with a ‘lighter design’ – less materials

- To aid the convection of air and the cooling as it travels up through the tower

- Low maintenance and operational costs

- Resist weathering and winds ensuring a long life cycle

- Large cooling capacity

- Minimal fogging

Definition of Hyperboloid

According to Merriam Webster, a Hyperboloid shape is defined as:

a quadric surface whose sections by planes parallel to one coordinate plane are ellipses while those sections by planes parallel to the other two are hyperbolas if proper orientation of the axes is assumed – Merriam Webster

Yup… I know… to put simply, if you look at a cooling tower, that’s the shape…

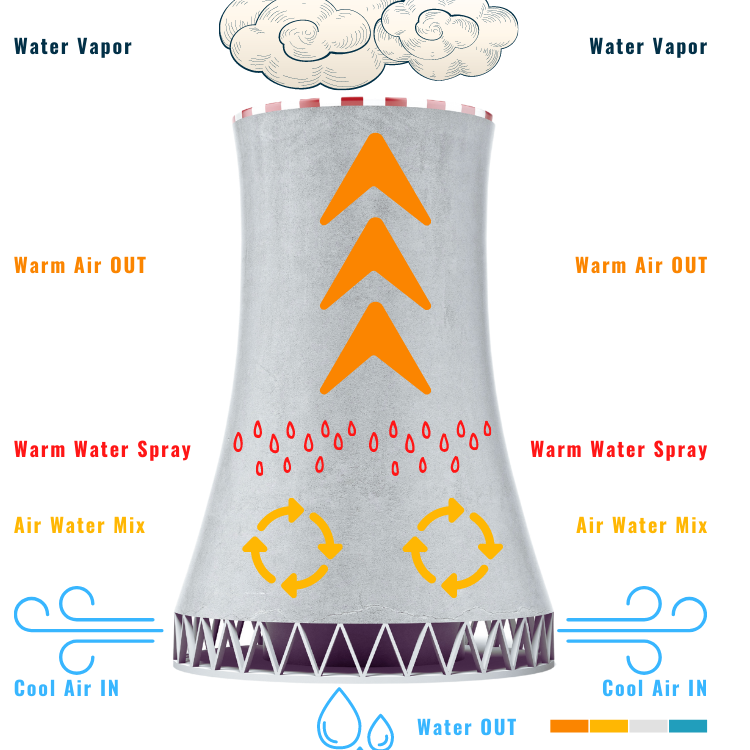

How does a Hyperbolic Natural Draft Cooling Tower work?.

Natural draft towers operate with no mechanical fans; much like the spray pond above, it uses spray nozzles within the tower that introduce the warm water that is to be cooled at a set height to the surrounding air.

After the water has been atomized, creating tiny water droplets will interact with the air transferring its heat via evaporation.

The air will increase moisture and temperature, become less dense, and rise through the tower, using ‘the chimney/stack effect.’

As the air rises, it will draw in cooler air through holes/vents constructed into the bottom of the tower. The cooler air will maintain the process of warming up as it comes into contact with the water, transferring heat, and flowing up through the tower.

The cycle is continuous, as long as there is load and water flow.

Once the hot air has reached the top of the structure, it will move into the natural atmosphere.

The water, once cooled, will drop to the base of the cooling tower, where it will be collected in a basin and pumped back into the cooling system to be recycled.

Operational benefits of the Natural Draft Cooling Tower

- Minimal electrical power required as no mechanical fans

- Low maintenance as limited no moving parts, maybe some blockages at the nozzles

- Low corrosion due to the use of materials such as stainless steel and concreate/cement

- Reduced requirement of space to construct compared to ponds

Frequently Asked Questions

References:

The following documents and websites were referenced for this article.

- Cooling Ponds – A survey of state of the art [Hanford Engineering Development Laboratory]

- SPX Cooling Website

⬛ Related Articles

COOLING TOWER | What is a Sweeper System?

MAKEUP / BLOW DOWN | Cycles of Concentration

COOLING TOWER | Inspecting & Cleaning Overview

COOLING TOWER | Pre-Commissioning Checklist and download

COOLING TOWER | Preventative Maintenance Inspections

COOLING TOWERS | All 38 components explained