To help manage and reduce the risk to life and property from fire damage, buildings should be fitted with automatic fire sprinkler systems. The NFPA notes that there are 4 types of Fire Sprinkler Systems as determined by document “NFPA 13, Standard for the Installation of Sprinkler Systems”, these systems are:

- Wet Pipe Systems

- Dry Pipe Systems

- Pre-Action System and,

- Deluge Systems

All other types of systems, for example, water mist systems and gas/clean agents are classed as ‘other type’, and managed under different documentation such as NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems, and NFPA 750, Standard on Water Mist Fire Protection Systems.

What is a sprinkler system?

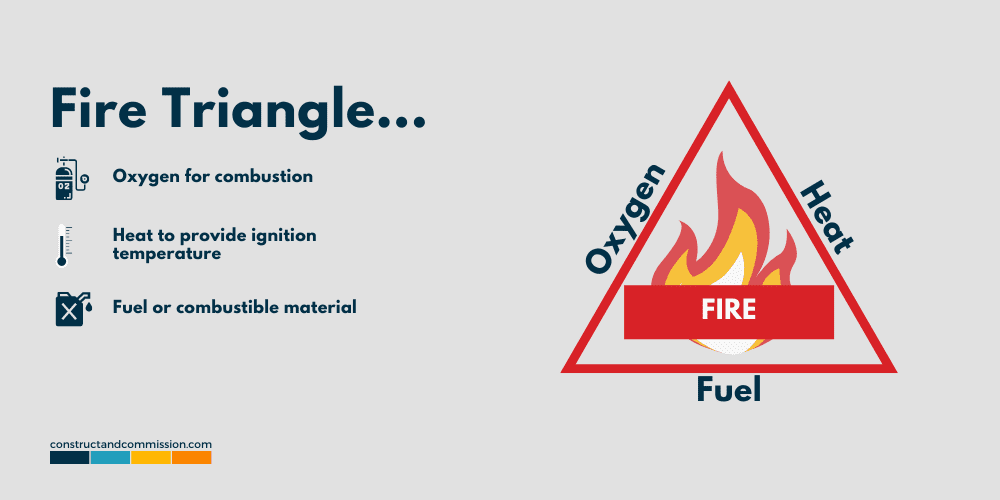

Sprinkler systems are designed to activate upon the detection of heat/fire in the space, then spraying water into the area it is occurring, this removes the heat from the source, suppressing and controlling the fire within a structure/building, as per fire triangle.

A simple systems components consist of:

- Individual sprinkler head / multiple sprinkler heads

- Pipework

- Automatic control valve

- Alarm system

- Permanent water supply

- Water tank

- Sprinkler pumps

Automatic sprinkler systems are used to detect the fire, to operate and provide water to suppress and control, and in some cases extinguish the fire.

Why install a sprinkler system?

Automatic sprinkler systems will form part of the overall strategy to meet the local, national, and insurance needs of the building, space, and client.

Some common reasons to install them are:

- To meet building regulations

- To meet code requirements

- To meet insurance requirements

- Reduce insurance premiums

- To protect against loss of life

- To protect assets/property damage

- Business continuation

- Consideration of environmental impacts if a fire occurs

They will usually be integrated into the overall building life safety strategy

Where are sprinkler systems installed?

Sprinklers are installed in various types of buildings to provide protection based upon the type of structure, space usage, and hazard being managed, they can be split onto ‘Commercial, Industrial & Residential’:

- Commercial buildings

- Offices

- High rise buildings

- Shops

- Hotels

- Data centers

- Parking garages

- Public Buildings

- Hospitals

- Libraries

- Sports halls

- Schools

- Museums

- Historic buildings

- Industrial

- Factories

- Laboratories

- Warehouses

- Storage facilities

- Aircraft Hangar [uses foam water]

- Residential Sprinklers

- Houses

- Flats

- Apartments

- Care Homes

Which type of sprinkler is best?

There is not really an answer to this question, as any fire system should be designed and installed in line with the relevant selection criteria and hazard classification.

Each different type will have its own advantages and disadvantages, usually based on the application it is intended for, and any regulation/code/insurance requirements of the building.

What is the most common fire sprinkler system?

The most common type of system is the Wet Pipe Sprinkler System.

What liquid is used in fire sprinklers?

Water is the liquid that will be used and discharged onto the fire. It is usually supplied from a water storage tank that is connected to the utility supply.

Sprinkler System Types

The below section describes the four types of systems that are noted above.

Wet pipe sprinkler system overview

A wet pipe sprinkler system is uncomplicated and reliable making it the most common type of system we see.

The pipework/system is permanently filled and charged with water, with the water discharge from the system occurring when heat congregates at a high level from the fire, eventually breaking a glass bulb within a ‘sprinkler head’ allowing water then to flow from the sprinkler pipe into the space.

Depending upon the size of the fire will depend on how many sprinkler heads are activated, if the fire is small then only one head will be needed

The water pressure and discharge velocity at the head is maintained with a set of sprinkler system pumps [jockey/main] that will automatically switch on when signals an overall drop in system pressure.

A valve is usually installed on the branch, and this will monitor the system and will send an alarm to the fire control system if within the pipework is noticed.

Wet sprinkler system sequence of operation

Below provides a very high level of the sequence of operation:

- Pipework is fully wet

- Fire starts in space

- Ambient temperature builds up around sprinkler head

- Ambient temperature around sprinkler head in excess of sprinkler head bulb temperature

- Sprinkler head breaks

- Immediate water discharge locally to fire

- Pumps start when a drop in pressure is noticed by the system

Dry sprinkler system overview

Dry pipe systems are near identical to the wet pipework fire system, with the only difference being that the pipework is not charged with water.

They are predominantly used within unconditioned spaces, when there is a risk of freezing temperatures, which, if the pipework was charged and full of water and frozen, would cause issues if needed to activate.

To ensure the system only responds when there is a drop in pressure, by opening the control valve allowing water to flow, the empty pipework would be filled/charged with pressurized air or nitrogen.

Activation will occur in a similar way to the wet system, a sprinkler head will activate, allowing air to pass through to the space, reducing the pressure in the pipework activating the control valve and system pumps.

They should not be seen as a ‘pre-action’ system, as they operate on a single interlock [air pressure drop], a pre-action system works on a double interlock.

Dry sprinkler system sequence of operation

Below provides a very high level of the sequence of operation:

- Pipework is Dry [no water contained]

- Fire starts in space

- Ambient temperature builds up around sprinkler head

- Ambient temperature around sprinkler head in excess of sprinkler head bulb temperature

- Sprinkler head breaks

- Drop-in pressure noticed by the system

- Control valve opens

- Water fills pipework

- Pumps start when a drop in pressure is noticed by the system

- Water discharges through the head locally to fire

Pre-action sprinkler system overview

More complex but used commonly where an accidental water discharge into the space being protected would be catastrophic to business and its operations such as data centers or museums.

There are 3 sub-types that cover the pre-action type system, depending upon the control function of activation allowing water into the system:

- A non-interlock system, where activation of the pre-action system valve will occur upon operation of a detection device [heat detector/smoke head/infrared sensor] OR sprinkler head [pressure drop]. This type will not provide much protection from accidental activation.

- A single interlock system, whereupon activation of any detection device [heat detector/smoke head/infrared sensor] the pre-action valve will allow water flow into the pipework and system.

- A double interlock system, find this is the most common, will activate the pre-action valve upon operation of a detection device [heat detector/smoke head/infrared sensor] and sprinkler head [pressure drop].

| Type of Interlock | Detector Activated | Sprinkler Head Activated [Pressure Drop] | Status of Pre-Action Control Valve |

|---|---|---|---|

| Non Interlock | Yes | No | Open [flowing] |

| Non Interlock | No | Yes | Open [flowing] |

| Single Interlock | Yes | No | Open [flowing] |

| Single Interlock | No | Yes | Closed |

| Double Interlock | Yes | No | Closed |

| Double Interlock | No | Yes | Closed |

| Double Interlock | Yes | Yes | Open [flowing] |

For the single interlock and double interlock preaction system, the temperature rating of the heat detector would usually be lower than the sprinkler heads. This is to ensure that the system is activated and ready to discharge once the bulb in the head breaks, creating a pressure drop in the system.

Deluge sprinkler system overview

Deluge systems are similar to that of the Pre-Action System, in the way the system control allows discharging of the water by a single interlock, being the detector.

The deluge sprinkler heads are installed within spaces deemed ‘hazardous’ and they are ‘open’, meaning that once the deluge valve has been activated and there is water in the pipework they will immediately discharge it into the space being protected, not relying upon the bulb in the sprinkler head to break, providing a very fast reaction time.

They will discharge into the complete space, from every head and not local to the fire as per the preaction system, which uses sprinkler heads with bulbs.

Fire codes, guides & standards

There are a few codes guides and standards that may be referred to within your project specifications:

UNITED KINGDOM:

- BS EN 12845 Fixed firefighting systems. Automatic sprinkler systems. Design, installation, and maintenance

- LPC Rules for automatic sprinkler installations incorporating BS EN 12845.

- BS 9251 Fire sprinkler systems for domestic and residential occupancies. Code of practice

UNITED STATES:

- NFPA 13, Standard for the Installation of Sprinkler Systems

- NFPA 3, Standard for Commissioning of Fire Protection and Life Safety Systems

- NFPA 13D, Standard for the Installation of Sprinkler Systems in One and two-bedroom family dwellings and manufactured homes

- NFPA 13E, Recommended Practice for Fire Department Operations in Properties Protected by Sprinkler and Standpipe Systems

- NFPA 13R, Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies

⬛ Related Articles

NFPA 13 SPRINKLER | Hydrostatic Testing Method with Template

SPRINKLER PIPEWORK | Pre-Commissioning Checklist