Fire dampers are an integral part of a building’s fire protection system and are required as part of local and country codes. This article will cover what we need to know about them and lead to other articles to ensure they are installed and tested correctly*.

What is the purpose of a fire damper?

To maintain the required fire rating to walls, partitions, barriers, or floors when ducts or other air transfer openings penetrate them, building codes and regulations require that fire dampers are installed to provide separation, in the event of a fire, between compartments restricting it spreading. Protecting people and property.

When should fire dampers be installed and when are they required?

To understand if fire dampers are required to be installed within a building or project, the specifications, drawings, statutory requirements, codes, and regulations should be reviewed.

If we quickly look at a few of these types of documents…

Project Specifications

Usually, there will be a statement in the project design specifications noting something like:

‘Include the cost and works for all fire dampers to be manufactured, installed, and tested, complying with all statutory requirements even if not shown on the project drawings.

So basically, if there are no dampers shown on the drawings, they should still be installed if noted in the statutory requirements of the location we are working in.

Drawings

The above statement within the project specifications notes that we should not rely upon the drawings to understand if the dampers are required or not. So a full review should be conducted to understand if there are any areas within the building where they would be needed but are not shown.

Statutory Requirements/Codes/Regulations etc

In reality, it will be down to the statutory requirements, codes, and regulations to understand if fire dampers are required and which type.

The following documents can be reviewed to understand the expectations:

- BS 9999 Code of Practice for Fire Safety in the design, management and use of buildings.

- International Building Code [chapter 7]

- NFPA 80 – Standard for Fire Doors and Other Opening Devices

Manufacturing Requirements

Fire dampers can not be manufactured by anyone; they need to be designed and manufactured according to specific requirements dictated by the Underwriter Laboratories [UL] Standards.

Underwriters Laboratories is a company that provides global safety science and engineering. They enable companies and manufacturers to demonstrate safety, strengthen security, deliver quality products or services of any kind while complying with all the necessary regulatory standards in their respective countries.

Manufacturers should usually prove that they have manufactured their fire dampers under the following standards:

| Standard | Description |

| UL 555 | The standard for Fire Dampers |

What is the difference between a Fire Damper and a Smoke Damper?

While they can look similar on the surface, there are clear differences between a fire damper and a smoke damper.

Fire Damper

Fire dampers are designed in line with UL 555 and installed in ventilation systems, ducts, and air transfer openings. Their purpose is, once the heat from the fire or smoke activates it, it will close. Once the damper is closed, it will cut off and interrupt the airflow into adjacent spaces stopping flames from spreading, thus creating a fire barrier.

Smoke Damper

In line with UL555S, smoke dampers are designed to be a low leak damper that is usually motorized so it can be shut down and closed in the event of a fire and opened again if needed to control the ventilation systems and subsequent smoke from the spaces of the building.

How to select a fire damper

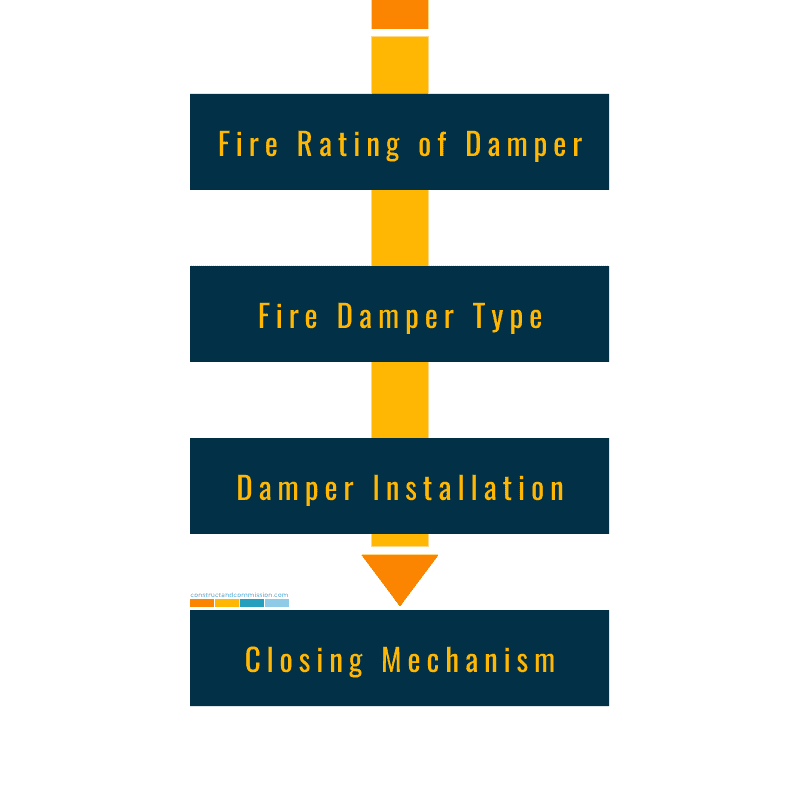

Selecting a fire damper for the correct use fortunately is quite straightforward, with the following being considered:

- What fire rating is required?

- What fire damper to use [Type]?.

- What type of installation is required?

- Type of closing mechanism should be used?

What Fire Rating is required?

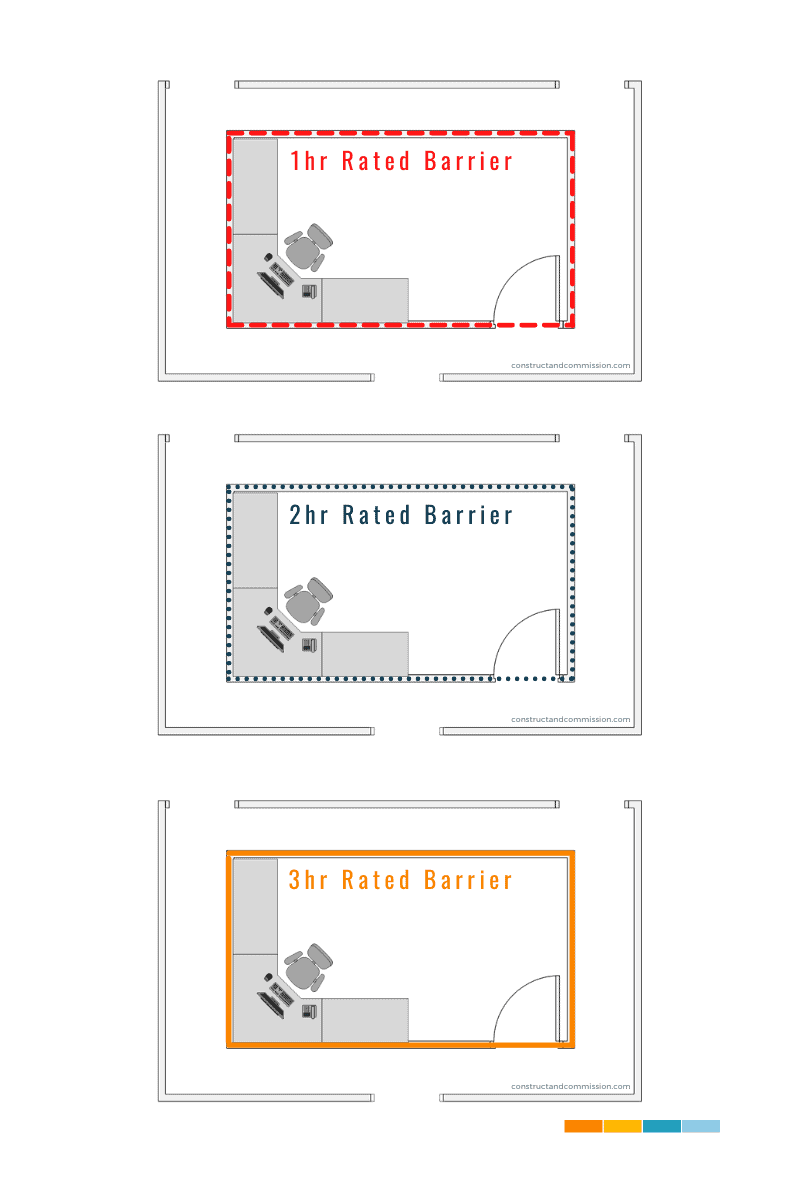

Commonly fire dampers will be rated and manufactured for a time period of 90 minutes or 180 minutes [1.5hrs or 3hrs], according to the International Building Code [717.3.2.1 Fire Damper Rating] the following is required:

| Type of Penetration | Minimum Damper Rating [hrs] |

| Less than 3-hour fire-resistance-rated assemblies | 1.5hrs [90 minutes] |

| 3-hour or greater fire-resistance-rated assemblies | 3hrs [180 minutes] |

Each individual project can be very different so to understand the rating required, the architectural/interior fit-out drawings should be reviewed and understood. Architectural drawings will detail the external and internal wall layouts that will be constructed.

There will be a drawing called ‘Fire Compartmentation Layout’ (or similar). These drawings will detail the expected fire rating of the different walls, ceilings, floors, etc., via a key representing different ratings.

The below graphic shows a common key used but make sure to read and understand your own drawings and keys to select your dampers.

What type of Fire Damper to use?

When trying to understand which type of fire damper to use, we need to ask various questions to get us there:

Type of system the damper is for, dynamic or static?

A dynamic fire damper is one where it has been designed to close with the fans still operating [under pressure]

A static fire damper has only been designed to close with the airflow off [usually a VAC trip type situation]

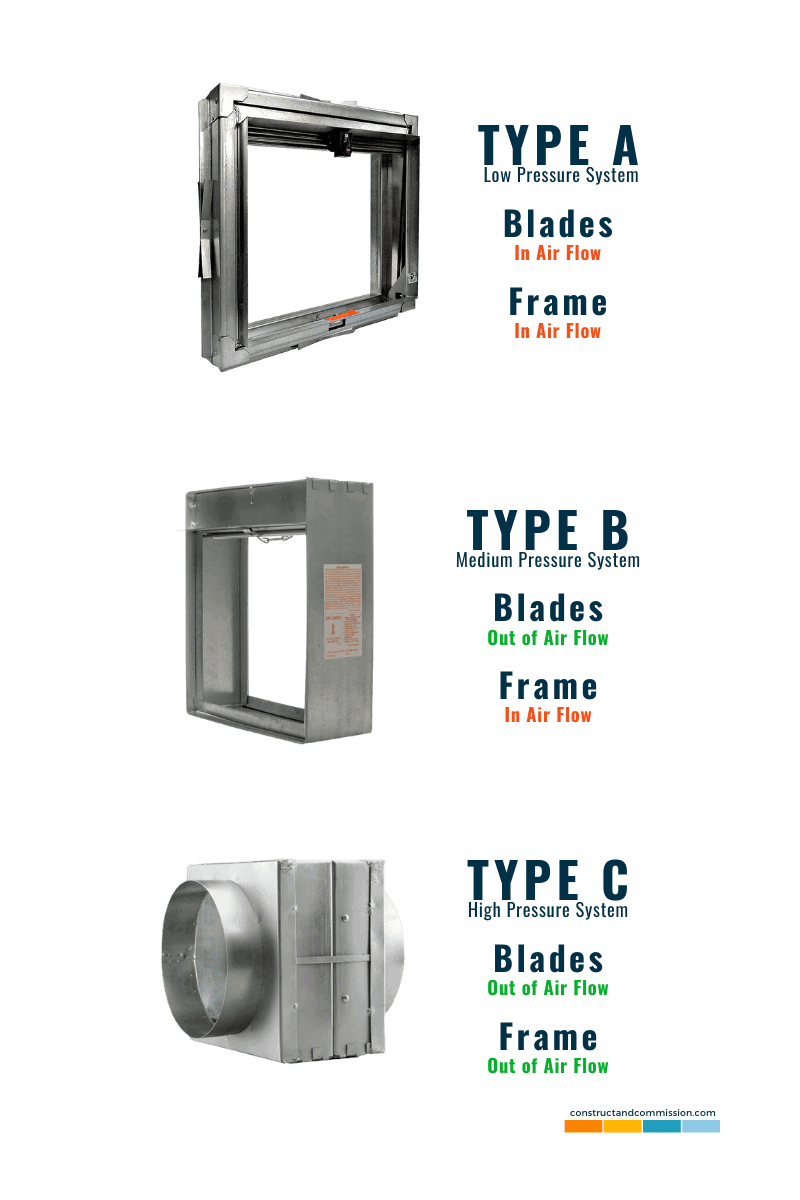

Type of system pressure?

The system pressure should be reviewed to understand what performance would be required from the fire damper.

| System Type | System Pressure | Frame in/outside of the airflow | Blades in/outside of the airflow |

| Type A Fire Damper | Low Pressure/Velocity | In | In |

| Type B Fire Damper | Medium Pressure/Velocity | In | Outside |

| Type C Fire Damper | High Pressure/Velocity | Outside | Outside |

Type of ducting that damper is being installed into?

Is the ducting rectangular or circular?

Size of ducting that the damper is to be installed into?

Depending on the size of the ducting a different type of damper may be required [curtain type or multi-blade type], covered in detail below.

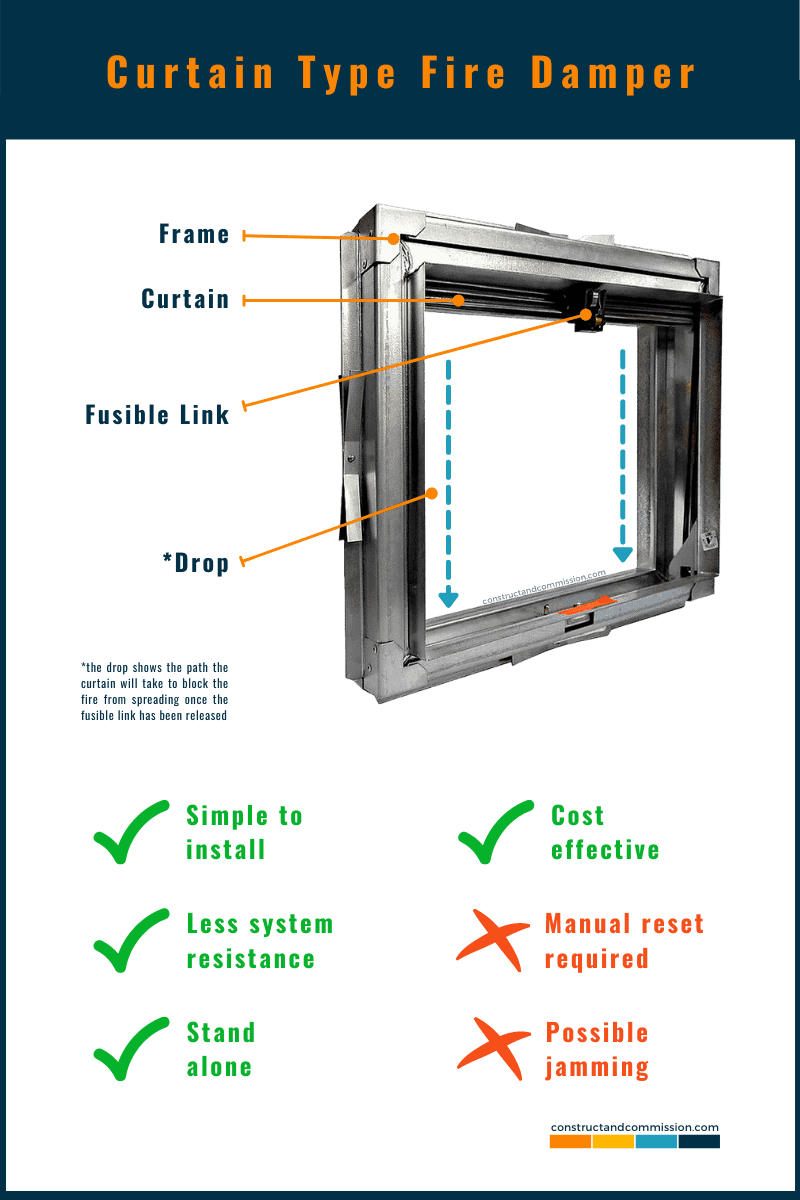

What is a curtain-type fire damper/fusible link fire damper?

A curtain-type fire damper or usually referred to as a fusible link fire damper is the most common of all fire dampers found on a project and operates via activation of a fusible link, releasing a curtain that drops under gravity aided by a spring to provide a barrier between different zones of a building.

They are the most common as they are the simplest to install, stand-alone [needing no interfaces], and most cost-effective.

Their downside is that they are manual reset, meaning an engineer will need to reset the damper physically, and they can sometimes become problematic by jamming.

| Positive [+] | Negative [-] |

| Simple to Install | Manual reset required |

| Less blades in airflow reducing resistance on the system | Can be known to jam, affecting the closing of the damper |

| Stand alone | Rated for closure under ‘static conditions’. All fans should be switched off. |

| Cost-effective | Used for smaller sizes of duct only |

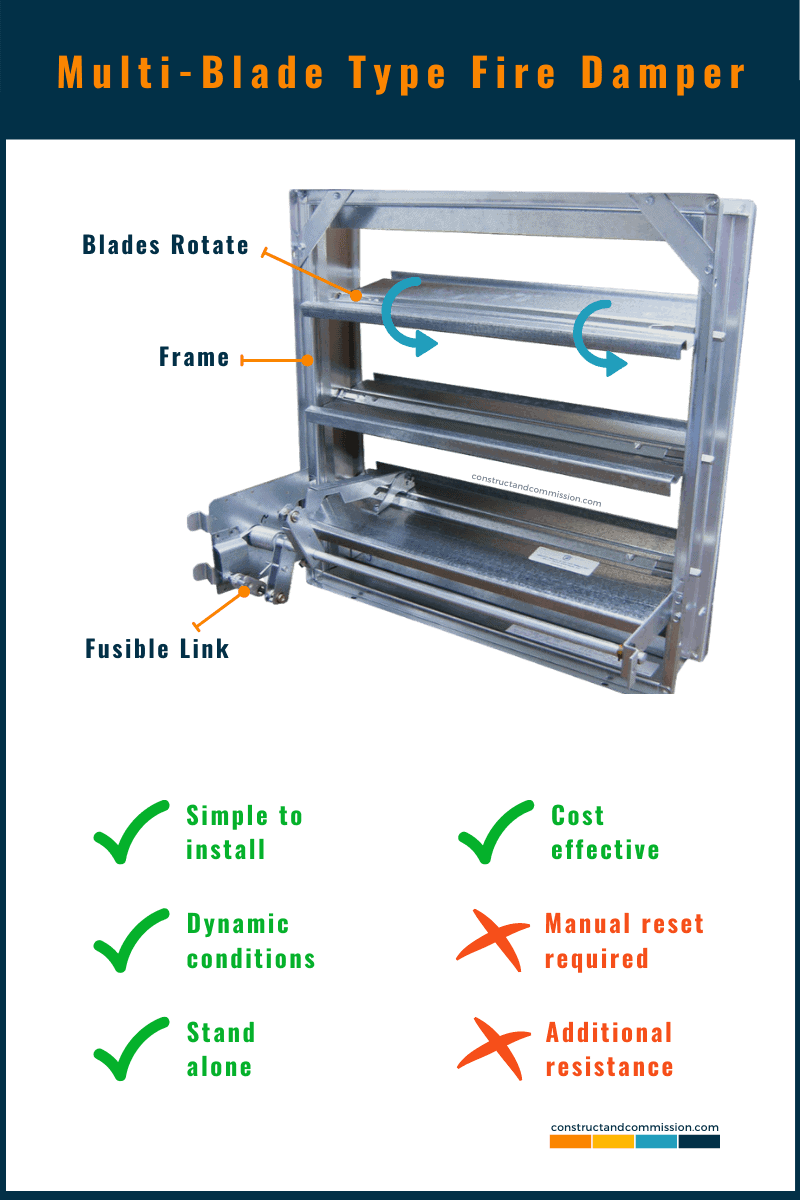

Multi-blade type fire damper

Multi-blade dampers operate in a similar way to the curtain type damper in that they utilize a fusible link to close the blades. They should be used when the size requirements mean that the drop-type curtain damper is not feasible due to the effort to reset them and operate.

The dampers are constructed similar to a multi-blade volume control damper, with blades in the airstream that can be opened and closed with a manual lever/handle via a spindle connected to the frame.

Like the curtain fire damper, they are simple to install, stand-alone [needing no interfaces], and cost-effective.

There are not many downsides that we have seen, apart from needing to manually reset them where, on larger dampers with multiple handles, it can be problematic if the correct access is not provided.

In a nutshell, the reason to use this type of damper over that of a curtain type is the size.

| Positive [+] | Negative [-] |

| Simple to Install | Manual reset required access could be an issue if not planned correctly |

| Stand alone | Blades in airflow creating additional resistance on the system. |

| Cost-effective | |

| Can be used for closure under ‘dynamic airflow conditions’ – fans on. | |

| Used on larger duct installations |

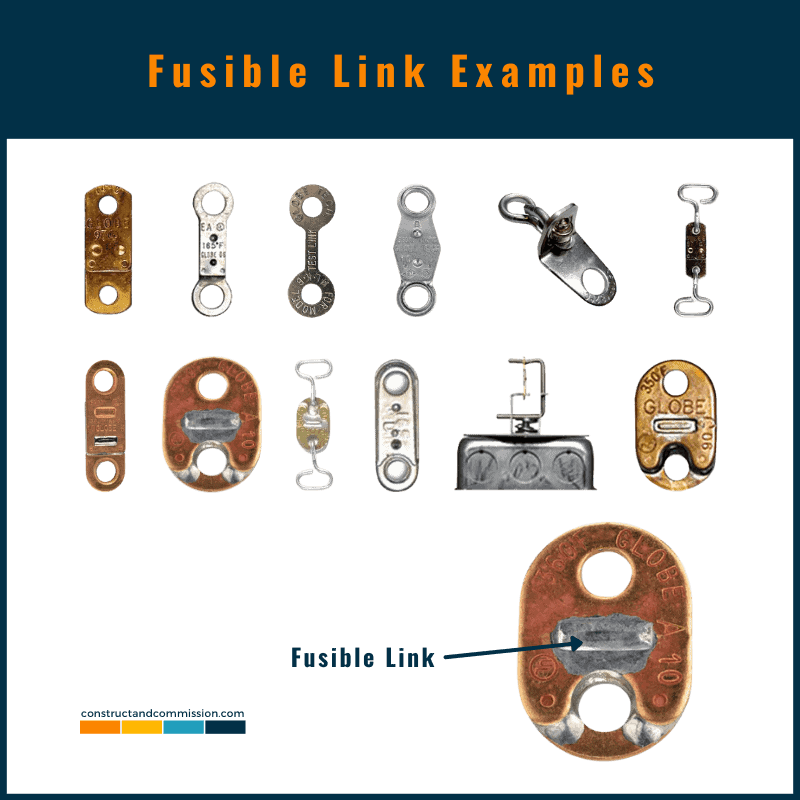

Fusible links/Fire damper link

For the fire dampers to operate and provide the required protection when needed, a thermal link is used to activate the damper.

What is a fusible link?

A fusible link is a UL-approved, 2 part fixed temperature heat detecting device soldered together and employed to restrain the operation of a fire damper until its designed temperature is reached. Upon that time, it will release, allowing the damper to close. They will usually require to be replaced if ever activated.

There are various types of links available, and the design will usually be specific to the type of damper/damper manufacturer being installed.

Underwriters Laboratories have the following standard for the manufacturing testing of thermal links. UL tests the links via oven tests, oil bath tests, corrosion & load tests for sustainability and reliability before certificating them.

| Standard | Description |

| UL 33 | The standard for heat-responsive links for Fire-Protection |

Fusible link temperature/load ratings:

As detailed above, fusible links are rated to fail/break at a certain temperature. Therefore, until their rated temperature has been met, they can hold the load [damper] open.

According to the International Building Code [717.3.3.1 Fire Damper Actuation Device], the fire damper actuation device shall meet one of the following requirements:

| Operating Temperature |

| approximately 50ºF (10ºC) above the normal temperature within the ducting system, but not less than 160ºF (71ºC) |

| the operating temperature shall be not more than 350ºF (177ºC) where located in a smoke control system |

Below notes the ratings that can be purchased from the manufacturers

| Temperature | Description |

| 165ºF (74ºC) | Generally deemed as standard |

| 212ºF (100ºC) | Optional |

| 285ºF (141ºC) | Optional |

What Type of Installation is Required for a Fire Damper?

A complete review of the drawings should be conducted to understand the orientation that the fire damper will need to be installed, and the type of compartments they are covering.

Horizontal Barrier – this will be anything that is installed in the horizontal plane, such as floors and ceilings.

Vertical Barrier – this will be anything that is installed in the vertical plane, such as walls.

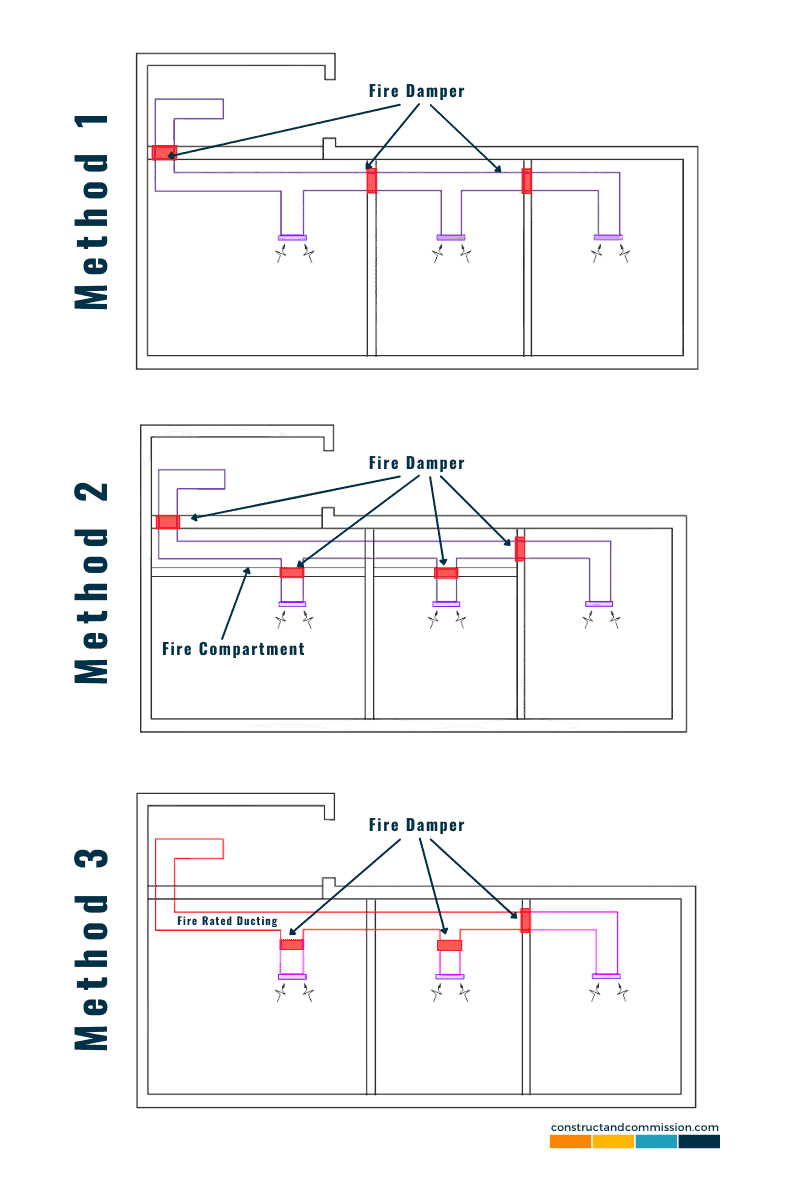

Within British Standard | BS:9999, it notes that there are generally 3 methods of installation that would incorporate the use of fire dampers.

- Method 1 – Protection using fire dampers

- Method 2 – Protection using fire-resisting enclosures

- Method 3 – Protection using fire-resisting ductwork

See below a summary of methods and graphic highlighting configurations.

Method 1 – Protection using fire dampers

This method focuses on using the fire damper as the primary fire barrier control when a duct is penetrating a compartment. The ductwork provides no protection.

The below graphic provides an example of how this can be interpreted.

Note: the BS standard states that a thermally operated damper should not be used to protect escape routes or used in smoke control systems, kitchen extract systems.

Method 2 – Protection using fire resisting enclosures

Fire dampers are used and installed between a fire enclosure and the common space.

Method 3 – Protection using fire-resisting ductwork

The fire dampers are used in conjunction with similar rated ducting. They create a barrier between the ducting, which facilities as a fire barrier, and the common space.

What type of closing is needed?

As noted, there are 2 types of fire damper, the fusible link curtain type and the fusible link multi-blade type. Usually, for closing, the multi-blade would be used for larger ductwork installations where it would be difficult to reset the curtain/drop type damper or fir dynamic airflow conditions [fans running].

Each installation should be assessed and the manufacturer’s advice sought.

Access to and Identification of fire dampers

In order for the dampers to be periodically tested and maintained, adequate access should be provided that is large enough to facilitate this.

We should ensure that the access should not interfere with the integrity and fire rating of the assemblies.

For identification, each access point should be permanently identified with a sign noting the fire damper, and clearly viewable externally.

Can a flexible duct be installed across a fire barrier:

No, according to the codes, flexible ducts should not be installed in such a way that they cross through fire barriers.

Fire damper maintenance requirements

Within the UK, under The Regulatory Reform (Fire Safety) Order 2005, section 17 – Maintenance, notes

“Where necessary to safeguard the safety of relevant persons the responsible person must ensure that the premises and any facilities, equipment and devices provided in respect of the premises under this Order or, subject to paragraph (6), under any other enactment, including any enactment repealed or revoked by this Order, are subject to a suitable system of maintenance and are maintained in an efficient state, in efficient working order, and good repair.”

This imposes employers’ responsibility to ensure that all fire systems are maintained and in good working order.

Under this guidance, and as fire dampers play a large role in stopping the spread of fire, they should be subject to a regular maintenance regime.

Who can test fire dampers?

The British Standard BS: 9999 states that a competent person must test fire dampers after installing and at regular intervals not exceeding two years.

There is currently no formal certification to our knowledge, so what does a ‘competent person mean?’

A competent person, in this instance, would mean anyone who is familiar with and understands the codes, guides, and standards relating to maintaining, testing, and documenting fire dampers and has experience in operating them.

Related Articles

FIRE DAMPERS | Detailed Guide to Testing

FAN COIL UNIT | Week, Month, 6 months, Year & 4 Year Inspections Listed

FAN COIL UNITS | What, Where & How

DUCTWORK | Pre-Commissioning Checklist

FAN COIL UNIT | Onsite Functional Testing Procedure with Template

FIRE DAMPER | Pre-Commissioning Checklist

⬛ Latest Articles

DATA CENTER | Commissioning Guideline & Template

DATA CENTER COMMISSIONING | What is it?

TIER V Platinum Data Center | What is it?

BUILDING SYSTEMS MANUAL | How to Write One with Roles

SPRINKLER PIPEWORK | Pre-Commissioning Checklist

⬛ Author

*Disclaimer:

Please understand that this information is provided as a high-level overview of fusible link fire dampers.

As there could be changes to codes, guides, and standards and could be different between different countries/locations/projects/types of installations, the reader should make themselves fully aware of those requirements.

Users should only use this information at their own risk.