Pneumatic Pressure Testing, in this instance, is a non-destructive test used to prove the integrity of a pipework system or vessel before conducting a hydraulic test to ensure no obvious leaks or open ends.

This non-destructive testing method uses a medium of air introduced to the system before being pressurized via a compressor to a predetermined and specified pressure, usually 0.5 bar / 7 psi.

🟩 Why conduct a low-pressure pneumatic test?

A Low-Pressure Pneumatic Leak Test is a low-impact / low-risk air test usually conducted before a Hydrostatic Pressure Test to ensure no obvious leaks, open ends, or risks of general water damage to the areas and furnishings where the pipework, system, or vessels are installed.

To see more on Hydrostatic Pressure Testing see our article 'HYDRAULIC PRESSURE TESTING | Explained with Templates'

🟩 What are the dangers of conducting an air test?

The are a few things that need to be considered and would be a risk when completing this type of work:

- Ensure that the pressure used will not stress the overall system integrity,

- Equipment is rated to the requirements of the test,

- Test pressure is not used that would introduce significant risk to the health, safety, and well-being of the operatives, engineers, and general staff involved or in the vicinity of the works.

🟩 Can the test cause damage to the system?

As noted above, YES, if the pressure is too high, it could impact and damage the overall system. Care should be taken to ensure that all systems, components, and equipment would not affected.

We would usually intentionally use low pressure when it comes to this.

🟩 Other phrases for pneumatic pressure testing

We have all encountered different phrases used when doing this type of test, depending on where we are.

Here are a few we have heard; drop us a line on Linkedin if you have any others that can be added:

- Air pressure test,

- Air tightness test,

- Pneumatic leak test,

- Pressure tightness test,

- Pneumatic integrity test,

- Airworthiness test,

- Compressed air test.

🟩 Pressure testing definitions

As with Hydrostatic Pressure Testing, there are a few definitions, as below, that we need to understand and will aid us in our understanding:

| WORDING | DEFINITION |

|---|---|

| Maximum Working Pressure | Maximum working pressure' is defined as the 'maximum pressure in the system during normal operation' and comprises of: 1. System Static Pressure [head or height of the system]. 2. System Pump pressure. The maximum working pressure is likely to be at the base of the system where the systems static pressure is greatest - very important if dealing with high-rise buildings, etc. |

| Testing Pressure | The test pressure is the pressure to be applied to the system during pressure testing under static conditions [pumps not running]. |

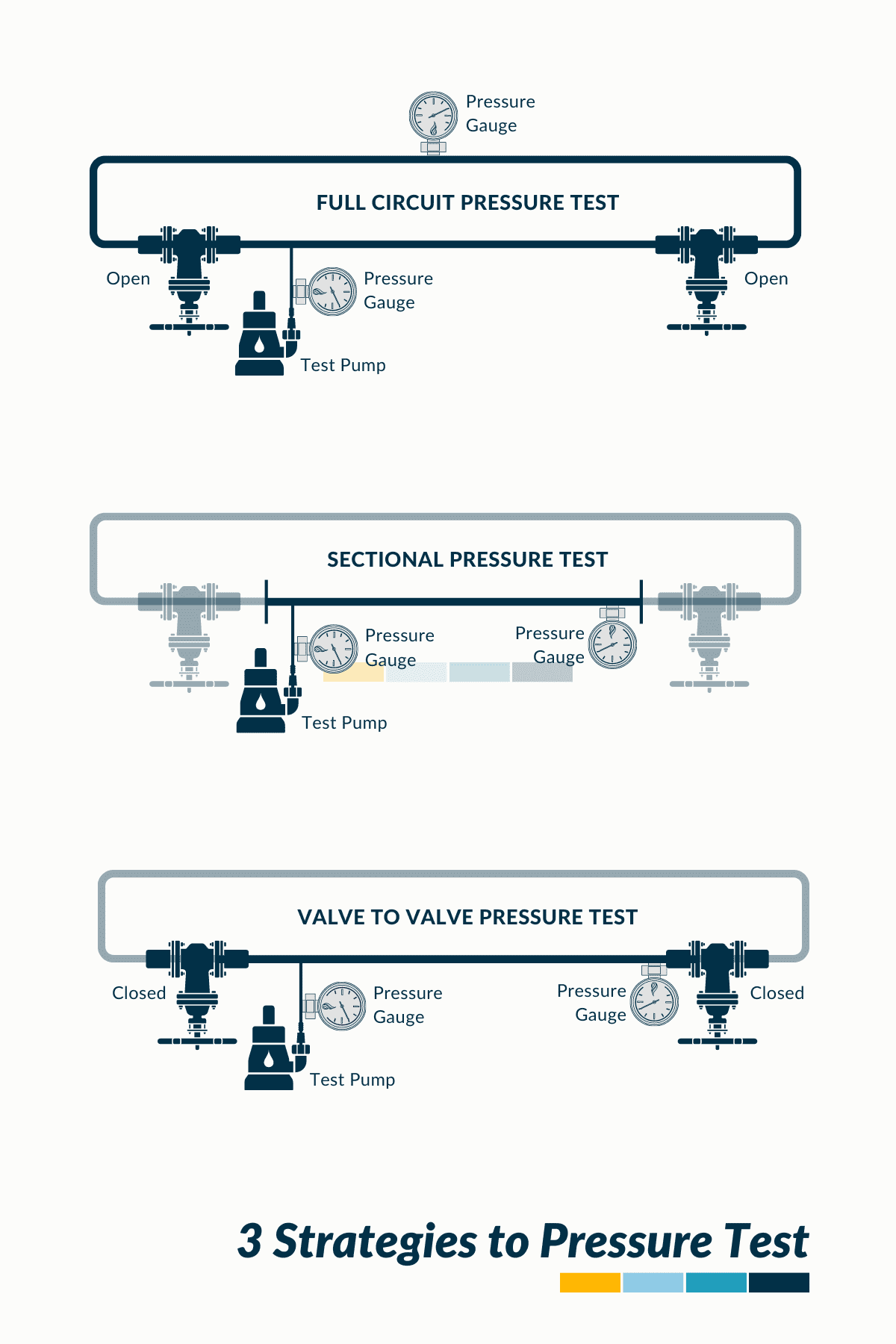

| Total System Pressure | Total System Pressure' will cover all pipework, joints, equipment, etc for a complete system. This is usually the best and quickest way to test, but subject to the system size and configuration. Commonly completed after the Pipework Flushing and Cleaning Stage of the Onsite Commisisoning Process. |

| Sectional Test | Sectional Pressure Testing' will involve splitting the complete pipework/equipment into various smaller sections by blanking off each section. This method is usually used on larger projects where testing the complete system at once is not feasible. Usually completed before water flushing etc. |

| Valve to Valve Test | Valve to Valve Testing' is used similar to a sectional test, but in this case, the valves are used as the blanks. Testing will go to the back of the valves or through the valves. As the valve to valve testing is completed the whole system will be covered |

🟩 Types of systems and materials testing covers

Within the construction industry, pressure testing can be used on the following types of systems and types of materials:

| System Type | Common Materials |

|---|---|

| Incoming mains water | HDPE |

| Domestic water supply | Copper |

| Hot water system | Copper |

| Grey water | PVC |

| Flush water | Copper |

| Irrigation systems | Galvanized |

| Condenser water | Galvanized |

| Chilled water | Steel / Copper |

| Heating system | Steel / Copper |

| Sprinkler system | Steel |

| Hose reel system | Steel |

🟩 How does pneumatic testing work?

Pneumatic testing involves filling the pipework system or component with a gas [usually nitrogen or air], then pressurizing it to a safe level to test its integrity.

The pressure is usually created using a compressor or pressurized bottle connected to the system; as the pressure inside the pipework/system increases, it starts to exert a ‘pneumatic force’ on the internal walls of the pipework and any joints or fittings that are connected and installed.

If there are any weak points in the system, such as a faulty joint, a crack in a pipe or open ends, the pneumatic pressure will cause the system to fail at that point, either by causing a leak or by causing the system to rupture – resulting in a failed test. If there are no weak points, the pressure will remain in line with the pressure that was created.

Once complete, the works can move on to the hydraulic pressure testing.

OPEN TEMPLATE of our PNEUMATIC & HYDRAULIC PRESSURE TESTING Method Statement including INSTRUCTIONS, that can be downloaded allowing editing and clean exporting for your project/company use.

All as per the format and layout are shown in the sample document, at the end of this article.

🟩 Why is pneumatic testing more dangerous than hydraulic?

Pneumatic testing can be more dangerous than hydraulic due to the nature of the test medium being used. In pneumatic testing, compressed air is used as the test medium, while in hydraulic testing, water or hydraulic fluid is used.

Compressed air contains more stored energy than water or hydraulic fluid. This means that if there is a failure in the system or component being tested, the release of compressed air/projectiles can pose a significant risk to persons in the local environment or fabric of the building, causing more damage or potential harm than a release of water or hydraulic fluid.

Proper safety procedures and pneumatic and hydraulic testing protocols are important to minimize risks and ensure a secure testing environment.

🟩 What testing pressure should be used?

Each project will potentially have different requirements, so best to discuss them with your internal safety team.

As a pure rule of thumb, 0.5 bar / 7psi seems to be a common pressure used.

This is enough to provide pressure on a system but not enough to cause too many problems if anything fails or there is an open end.

🟧 What is considered unsafe pressure?

The question is usually, ‘what is a safe Pneumatic Pressure Test’.

A safe pneumatic test pressure will depend on several factors, such as the type of equipment being tested, its design, its intended use, the experience of the team, and how the risks are managed/mitigated.

In any testing pneumatic testing, always involve your safety department and reference the latest local codes, guides, and standards.

We have added a Pressure Conversion Table to the site see 'PRESSURE CONVERSION TABLE | Bar, Pa, Kpa & Psi' if want to read more

🟩 How long should pressure testing take?

Usually, if the system is steady for 10 minutes after the pressure has been introduced, it can move to the next stage of Hydrostatic Testing.

🟩 Tolerances

[+/-0] Any pressure drop would deem the test a failure across the stipulated period.

🟩 Pneumatic testing guidelines, regulations & standards

When completing any pneumatic testing, the work should be conducted to the requirements of any codes, guides, and regulations.

Below is a high-level list of some we have come across:

🟧 Guidelines/Standards

Although pressure testing is seen as a quick basic test that anyone can complete with a hand pump and a calibrated gauge, there are currently four guidelines that can be referred to that would allow the testing to be specified properly.

- ASME Process Piping Code B31.3 [USA developed]

- OSHA Technical Manual Section IV: Chapter 3 Pressure Vessel Guidelines [USA Developed]

🟧 Regulations

If completing this type of testing, then the following Regulations should be kept in mind:

- Pressure Systems Safety Regulations (PSSR) [UK developed]

- Health and Safety at Work etc. Act 1974 [UK developed]

🟧 Codes

And these codes:

- Approved Code of Practice (ACOP) L122 [UK developed]

🟩 Testing equipment to be used [PDF]

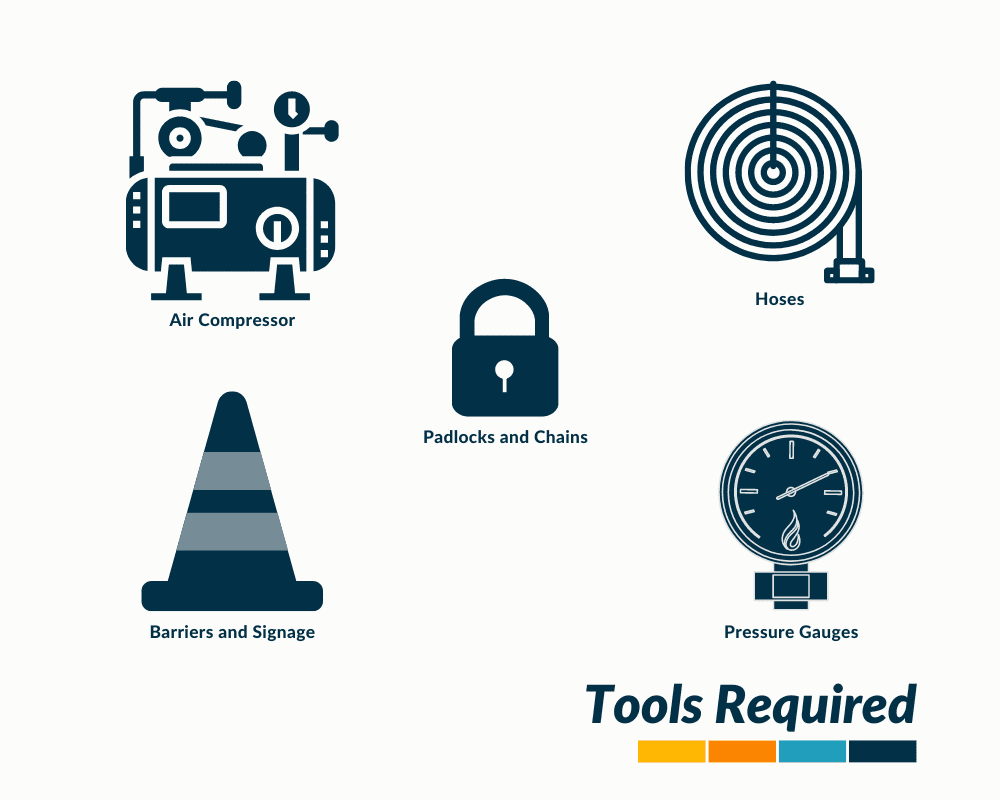

The following equipment will be utilized during the Pneumatic Testing works:

- Compressor/Gas Bottle: Generates the required pressure within the system.

- Hoses: these are flexible tubes/pipes, rated at the correct pressure, connected from the compressor/gas bottle to the system under test. They can also be used for looping and connecting other systems.

- Calibrated Pressure Gauges: used to measure and monitor the pressure within the system that is under test.

- Pad Locks and Chains: to lock off valves or other system components to ensure they cannot be inadvertently opened during the test.

[Add PDF download]

🟩 Pressure testing safety checklist

Before starting the work, a few requirements are needed to ensure the testing is completed safely.

🟧 Personal protective equipment [PPE]

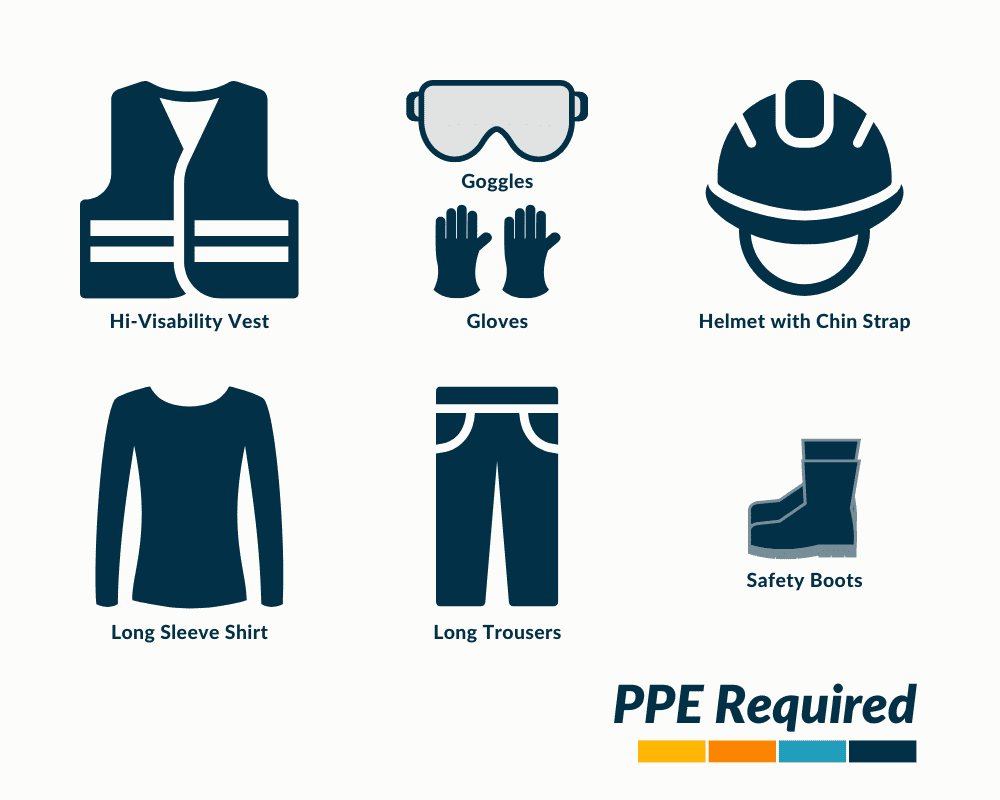

Personal Protective Equipment [PPE] refers to any equipment or clothing worn by anyone involved in the works to protect themselves from the hazards they will be exposed to.

Each project should be evaluated for its specific risks, but in general, the PPE that will be worn would be:

| Type | Protecting | Notes |

|---|---|---|

| Hi-Visability Vest | Designed to make the wearer more visible to others, typically in situations where visibility is low, such as in dimly lit areas. | |

| Goggles | Eyes | Provides protection for the eyes against impact, debris, chemicals, and other hazards that may be present during the works. |

| Gloves | Hands | Worn to protect the hands from potential hazards such as cuts, burns, and chemical exposure. |

| Helmet | Head | Protects the head from falling objects, bumps, and other potential hazards that may be present during the works. |

| Chin Strap | An adjustable strap that attaches to a helmet and is worn under the chin to keep the helmet securely in place and prevent it from falling off in the event of an impact. | |

| Long Sleeve Shirt | Arms | Worn to cover the arms and torso, providing protection against cuts, scrapes, and other potential hazards. |

| Long Trousers | Legs | Provides leg protection against cuts, scrapes, and other potential hazards. |

| Safety Boots | Toes/Feet | Designed to provide protection to the feet against potential hazards such as falling objects, sharp debris, and slippery surfaces. They should typically have reinforced toes and non-slip soles for added protection. |

🟧 Site safety equipment

Where PPE is worn to protect those completing or involved with the tasks, site safety equipment is used to allow them to carry out the work safely.

Items of equipment that could be used would be:

| Type | Notes |

|---|---|

| Safety Signage | Safety signage is used to warn people of potential hazards, provide information about safe practices, and direct individuals to safety equipment or exits. These signs are typically made of durable materials and display symbols or text that are universally recognized. |

| Barriers/Cones | Barriers and cones are used to cordon off areas where the works are being carried out or where there are potential hazards. They are used to prevent people from entering the areas and to ensure that individuals remain at a safe distance. |

| Spill Kits | Used to contain and clean up spills of liquids. These kits contain materials such as absorbent pads, booms, and gloves, and are designed to be easily accessible in case of an emergency. |

| Access Platforms | Provides a safe and stable platform for workers to carry out their tasks at height. Covering items such as scaffolding, mobile elevating work platforms [MEWPs], and ladders [where safe] |

| Fall Protection | Fall protection equipment is used to prevent workers from falling from height. This can include items such as safety harnesses, anchor points, and safety nets. Fall protection equipment is often required by law when working at height, and should be inspected regularly to ensure that it is in good condition. |

🟩 Pneumatic pressure testing method

Below are the steps necessary to deliver a successful pressure test.

🟧 Step 1 – Complete general pre-requisites checks

The checks, as detailed below, should be completed to ensure that everything is set up for the testing to commence:

| Ref | Details | Notes |

|---|---|---|

| 1 | All Technical / Material Submissions Status A | |

| 2 | All Drawings of System [Layouts & Schematics] Status A and fully marked-up showing clearly the testing areas and testing numbers, being proved via a visual inspection. | Where a different status is shown the following will be allowed: Status B - Testing can proceed as long as comments have been addressed and do not affect the testing. Status C & D - Testing will not proceed |

| 3 | Testing Method Statement reviewed and provided a Status A | Where a different status is shown the following will be allowed: Status B - Testing can proceed as long as comments have been addressed and do not affect the testing. Status C & D - Testing will not proceed |

| 4 | All Delivery Records Available for Inspection | |

| 5 | All Installation Inspection Records Available | For Inspection showing systems to be tested have been inspected by the Resident Engineering Team and, accepted as being installed in line with the project requirements. Where not available testing will not be allowed to commence. |

| 6 | All Permits are in place as noted in the 'Permit to Work' Section & system set up for testing, padlocks, protections, signage, etc. | Where not available testing will not be allowed to commence. |

| 7 | Items of equipment that may be affected by the higher pressures are isolated or removed and replaced with spool pieces. | Where not testing will not be allowed to commence. |

| 8 | All pipework fittings and equipment is rated for the pressure testing requirement. | Equipment, Hoses, Valves, Control Valves, Connections, Gaskets. This is can be an issue in high-rise buildings. |

| 9 | Calibration Certificates are available for all instruments and equipment and are within date. | |

| 10 | Pressure Gauge is installed at the lowest point and highest/furthest point of the system with a display/range applicable to the testing pressure. | If not they will need to be relocated or replaced. |

| 11 | Power is available if a compressor is being used | |

| 12 | All pipework joints are exposed, i.e not insulated to allow for observing of the system. | |

| 13 | System empty of water. | |

| 14 | System set up in line with any strategies, valves open/closed / blanks installed, etc. | |

| 15 | Hoses installed at low-level drain cocks and rated to required pressures. | |

| 16 | Operative and Engineers fully trained and where required hold a current relevant certificate to complete the works. |

🟧 Step 2 – Pipework installation checklist/inspection record

Before the testing and commissioning phase takes place, the following will be checked.

| Ref | Inspection/Task |

|---|---|

| 1 | Pipework is installed in line with the project drawings [size, location]. |

| 2 | Piping is free to expand and contract without noise or damage to hangers, joints, or the building. |

| 3 | Seismic restraints, where required, installed. |

| 4 | Pipework does not put undue stress on equipment, where connected and is bracketed to support itself. |

| 5 | All piping supports and hangers meet criteria set out in the specifications. |

| 6 | Piping is installed with sufficient pitch and arranged in a manner to ensure drainage and venting of the entire system. |

| 7 | Manual air vents are provided at high points in closed water systems. |

| 8 | Ensure all gaskets are installed and sealed. |

| 9 | Ensure that all bolts are installed as per manufacturer's instructions. |

| 10 | Any nipples installed are made of the same material as the pipe. |

| 11 | Any connections between copper and steel pipes are made with dielectric fittings. |

| 12 | A union is provided ahead of each screwed valve, trap, or strainer, and on each side of each piece of equipment and whatever needed to dismantle piping. |

| 13 | Any changes in pipe sizes are made with the proper size reducing fittings, reducing fittings, reducing elbow, or reducing tees. Bushings are not allowed. |

| 14 | All fittings meet specification requirements. |

| 15 | All fittings and ancillaries are rated correctly and inline with the pressure of the system. |

| 16 | All equipment requiring maintenance is accessible (valves, junction boxes, etc.). |

| 17 | Piping does not block access to equipment that is part of this system or another system (e.g., air terminal units). |

| 18 | Drain valves are provided at all low points in hose bib piping to facilitate seasonal draining. |

| 19 | All valves [isolation, commissioning, non-return etc] are installed as per the drawings |

| 20 | All strainers are installed as per the drawings and baskets are clean. |

| 21 | Pipework is insulated as per the specification and vapor sealed where required. |

| 22 | Piping is installed in a manner to ensure that insulation will not contact adjacent surfaces. |

| 23 | Any pipe openings are temporarily sealed to maintain piping system cleanliness. |

| 24 | All components including valves and controls are labeled in line with the project naming convention. |

| 25 | Instruments, flow meters, energy meters, and commissioning stations have been installed in line with the manufacturer's requirements and correct direction. This includes distances from turbulent flows etc. |

| 26 | All pressure gauges installed, and display scale as per design requirements. |

| 27 | Pipework has been magnetic weld tested, where specified. |

| 28 | Pipework has been ultrasonic weld tested, where specified. |

Here is our open copy [MS Word] of the GENERAL PIPEWORK Pre-Functional Checklist, for making life a little easier...

We have also recently formatted this checklist to [MS Excel] and included it as a Bonus for FREE.

So get an MS Word & MS Excel for the same price.

Once the above table has been verified and agreed upon, the Hydraulic Pressure Test can be commenced using the steps below, with the hand pump, valves, and gauges connected:

🟧 Step 3 – Raising the system pressure

Raise the system pressure by opening the valves to the compressor/gas bottle, then slowly raise the air pressure within the system in 0.1 bar / 1.45 psi increments.

Stop when the gauge reading meets the required testing pressure.

🟧 Step 4 – Allow the system to stabilize

Once the testing pressure is reached and verified, shut off the valves at the system connected to the compressor and allow the system to settle for 10 minutes.

If there is a drop in pressure during the 10 minutes, this could be due to the system settling; use the compressor/gas bottle to top-up the system, and ensure the valves are opened before and closed after completing [this will be the only time a top-up is allowed].

🟧 Step 5 – Confirm the system is stable

Once the system is stable, fill out the pressure testing certificate by documenting the required information.

✅ The testing time will now start.

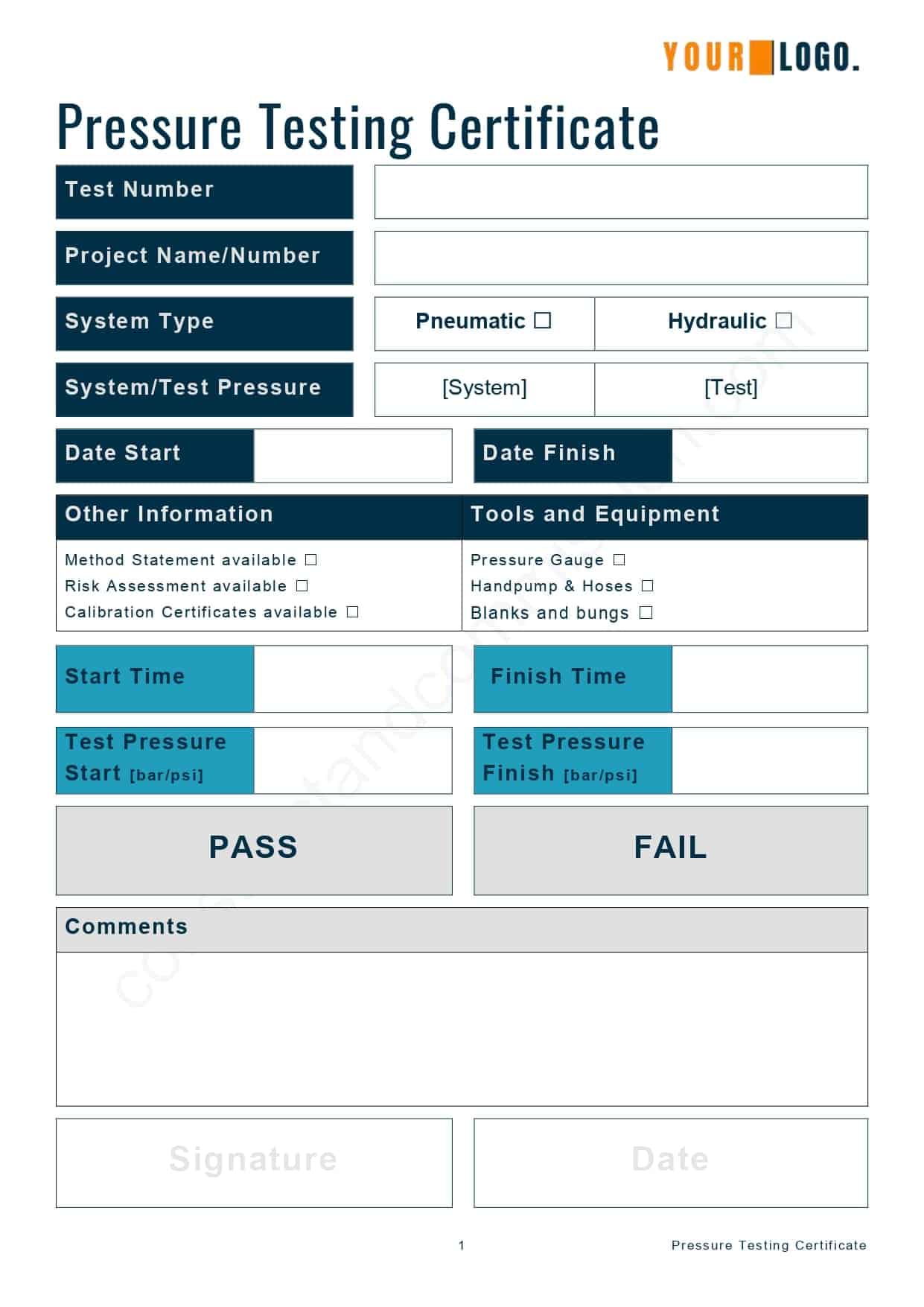

Here is a ‘Pneumatic Pressure Test Certificate Template’ that can be downloaded in PDF or MS Word.

⬜ Hydraulic pressure testing certificate template

The following certificate can be emailed to you for use in your works and reports from our shop; click the ‘Download’ button if you want a copy.

🟧 Step 6 – Testing started

Once Step 5 has been completed and verified, ensure that the testing pressure is held for the period noted in the contract documents and within the expected tolerances.

During the testing time, check the system and gauges for any signs of leakage or loss of pressure.

🟧 Step 7 – Completion of testing

✅ If no pressure loss is noted over the required time frame, the test can be completed and a Pass provided.

Finalize pressure testing certificate and file.

❌ If leaks or pressure loss are outside the tolerances noted, they should be investigated and addressed.

Failure of water tightness within a system will usually be noted at flanges, joints, or connections to equipment.

Once all remedial works have been completed, retesting will be conducted until the system passes.

Finalize pressure testing certificate and file.

🟧 Step 8 – Depressurize the system

Once everything has been confirmed as complete, safely depressurize the system.

🟧 Step 9 – Removal of testing equipment

When the testing has been confirmed as complete and passed, the compressor/gas bottle, gauges, and temporary valves/hoses should be removed, with any equipment checked or reinstalled to ensure normal status.

⬜ Pneumatic pressure testing method statement template

Here is an example of a pressure testing document, including hydrostatic and pneumatic, that can be purchased and downloaded in our shop; click the ‘Buy Now’ button.

⬛ Hydrostatic testing questions and answers

⬜ What is the difference between a hydro test and a pneumatic one?

A hydrostatic test uses water, while a pneumatic test uses a gas [air/nitrogen].

⬜ What is the maximum pneumatic pressure?

The pressure that the equipment or system is rated for and can contain.

⬜ What is the minimum psi for an air test?

The minimum psi for an air test would be around 7.25 psi [0.5 bar]

As a general requirement, always check with your health and safety department for specific allowances.

⬜ What is the holding time for ASME B31.3 pneumatic test?

According to ASME B31.3, the holding time for pneumatic testing should be no less than 10 minutes.

⬛ Related Articles

WATER LEAK DETECTION | How it Works and Testing Method

FAN COIL UNIT | Pre-Commissioning Checklist

FAN COIL UNIT | Installation Guideline

FAN COIL UNITS | What, Where & How

CENTRIFUGAL PUMP | Commissioning and Alignment

CRAC Unit vs CRAH Unit | What’s the difference?

![Pneumatic & Hydrostatic Pressure Testing Method Statement Template [MS Word]](https://constructandcommission.com/wp-content/uploads/2023/03/003f.webp)

![General Pipework Pre-Commissioning Checklist Template [MS Word] + [MS Excel]](https://constructandcommission.com/wp-content/uploads/2023/03/049i.webp)