Just installing new pipework for a closed-loop hydraulic system within a facility that is used for transporting heating/cooling water will not guarantee its internal cleanliness, when it comes to putting it into operation, we need to flush and chemically clean it to remove any debris and deposits that have built up through the manufacturing and installation process.

This article will cover an overview of:

- why we flush,

- what we flush,

- when we flush,

- how we flush,

- who does what,

- design considerations

- planning

- standards and guidelines

Once we understand the above, we will move on to a detailed method statement and process that can be used to flush and clean a closed-loop system.

Our article 'DYNAMIC FLUSHING | Procedure & Sequence' provides a step by step outline of a flushing and cleaning procedure.

Why Flush and Chemically Clean a Closed Loop Pipework System

Through the construction process and before fill and venting takes place, corrosion, biological films, scale, dirt, debris, oxidants, a few hard hats, a deck chair, a couple of tables, 1 steel toe capped boot [who knows where the other one is], and 57 high visibility vests, usually with the electrician’s company logo on the back, will be found in the system.

To see our full example of a method statement for the Flushing & Chemical Cleaning works, including the ongoing monitoring click here

Here is our Open Copy of our Flushing and Chemical Cleaning Method Statement in MS Word. With instructions

All the above will usually enter due to one of the following not being managed correctly:

- Pipework is being delivered in a dirty condition.

- Pipework not being stored onsite correctly, dirty areas, weather, humidity, general dust, and particles in the air.

- General installation and construction debris accumulates from cutting, welding, and screwing.

- Open ends of the pipework are not being protected once installed.

- Conducting hydraulic pressure testing, using water, and then leaving in the pipework or draining off but not allowing the internal surfaces to dry properly.

- Someone is not being paid on time.

- Scale build up

From the above, we will usually experience a common set of issues, depending on the problem, these could be depending on the time period:

- General flow rate issues around the system due to accumulation of debris.

- Blockages at strainers.

- Issues with control valves.

- Coils are being blocked.

- Coils not operating at required design loadings.

- Increased maintenance and shortened life expectancy due to corrosion of terminal units, major equipment, ancillaries, and pipework that the water comes into contact with.

- Increased usage and costs of chemical treatment

What we flush – Systems that are usually Chemically Cleaned and Flushed

In a commercial environment, general offices, and data centers, the following systems will usually be cleaned.

- Closed-loop chilled water systems

- Closed-loop heating water systems

- Condenser water systems [sometimes use a modified method as open-loop system]

When to Flush

The flushing will only commence after the pipework installation has been completed, pressure tested and is set up with all loops, equipment and components.

How do you flush a water system?

In simple terms, the high-level steps of the flushing process would be as follows:

- Ensure the system can be flushed properly via document reviews [drawings/specificaitons]

- Ensure the system is complete with installation approval and sign off

- Ensure the system is weld tested [where required by specification]

- Ensure the system is pressure tested

- Ensure the system is filled and vented

- Conducts a dynamic flush – Clean water is pumped around the closed-loop water system at specified velocities, depending upon its size to dislodge dirt, grime and material buildup.

- Backflush terminal units – reverse flush to remove any grime or debris before being introduced to the main system.

- Chemical Clean

- Passivation and inhibitor

- Ongoing chemical treatment of installation

- System Maintenance till handover

Who should be involved in the flushing and cleaning?

DESIGNER | CxA | GENERAL CONTRACTOR | FLUSHING SPECIALIST | CHEMICAL ENGINEER

Designer |

The flushing and cleaning works should be considered from the outset of the project, starting with the designer as they have the earliest input into how it can be completed and include the equipment and requirements from the outset.

Commissioning Manager |

The Commissioning Manager [CxA] will, during the commissioning ability review, check, and comment on the drawings and specifications to ensure that the system can be flushed successfully and that everything has been specified and noted to allow the contractors a chance when it comes to pricing the project.

The Commissioning Manager should reiterate the requirements within their commissioning specification.

If all the items have been considered above, then there should be no issues.

As we know though, usually none of the above has been considered and the contractors will try to claim money and time to adhere to the requirements etc.

General Contractor |

The contractor should ensure that they have the correct experience to complete the works and that all allowances have been made – experience, resources, costing, instruments, system modifications, equipment, and expected/anticipated programme [it’s often not a 5-minute job].

Flushing & Chemical Cleaning Specialist |

The role of the flushing & cleaning specialist is quite simple, to provide advice, knowledge, expertise, resource, and equipment to ensure that the flushing is completed to the project requirements.

Chemical Engineer |

The chemical engineer would be employed, either by the contractor or the flushing, specialist to provide advice, oversee, laboratory test, and supply the chemicals needed during the chemical cleaning, passivation, and ongoing maintenance of the system.

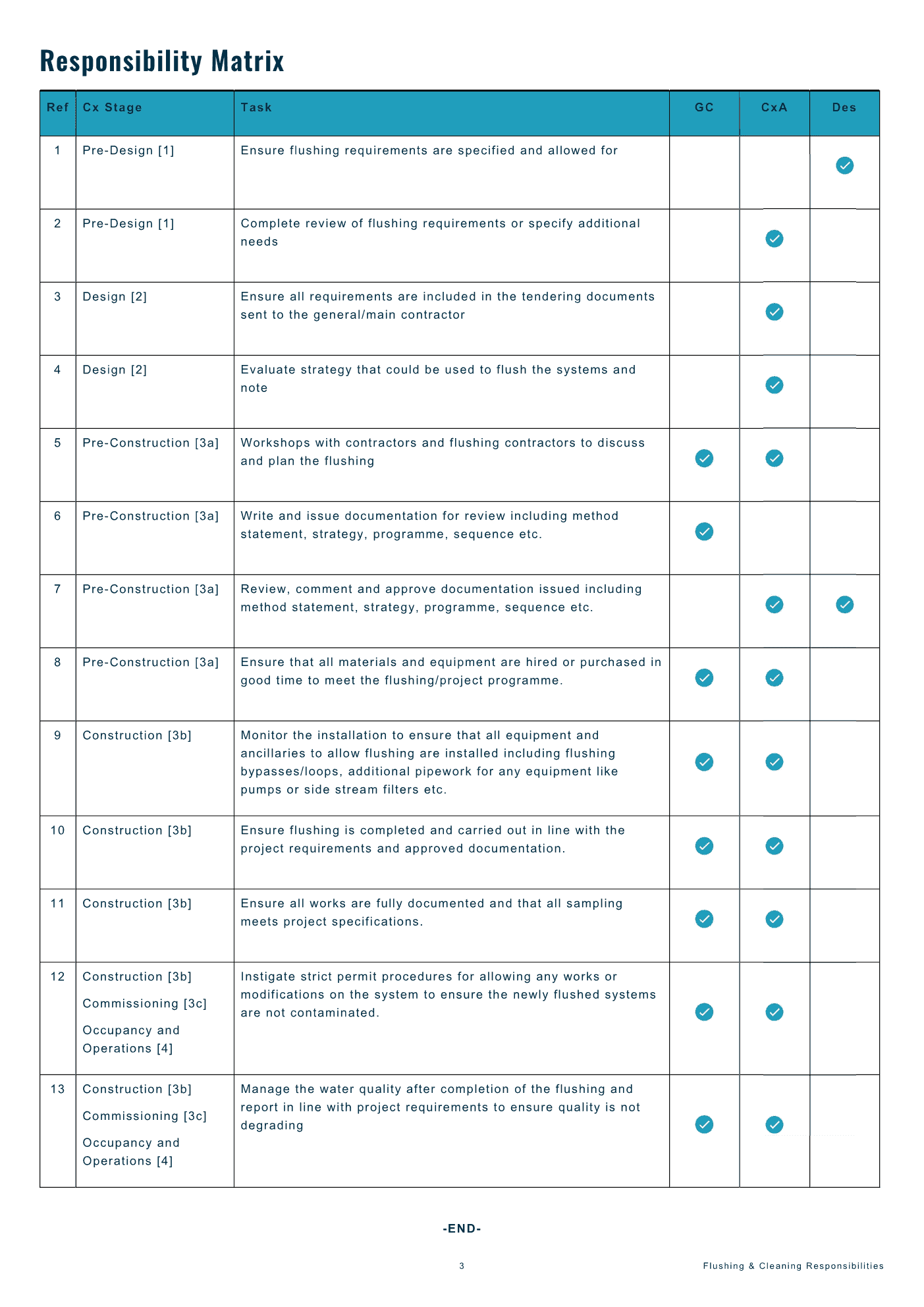

Responsibility Matrix

Grab a free copy of this responsibility matrix by downloading from our shop, click the ‘Download Here’ below.

Who should complete the work?

It is quite easy to think ‘just get the easiest and cheapest company who say they are able to complete the works. Get Bob from the ductwork contractor to do it’, but the cleaning and flushing works should be taken very seriously and carried out by an experienced company/engineering team who are specialized in this type of work having the expertise, manpower, and equipment to complete it successfully.

A qualified chemical engineer should also be employed to provide advice and expertise on the type of chemicals that are to be used, in what quantity, and at what stage, including site and laboratory analysis for the system.

We need to remember the consequences of this work if it is not completed properly. It will usually result in large additional costs and extensions to the programme/impact to the commissioning sequence.

Design Considerations

The designer, whilst completing their design, should evaluate any requirements needed to ensure that the system has been designed and all components included within the drawings and specifications to ensure that the systems can be flushed and that the tenderers fully understand, allowing for the works.

There are many areas that should be looked at, reviewed, and considered, some of these are listed below:

- Is installation a new standalone system or is it to be integrated into an existing system.

- What would the handover requirements be of the cleaned system to the operation team, are they specified?.

- Will, there be any requirements to maintain the system with chemical and water quality analysis.

- What chemicals and cleaning agents would be acceptable to be used?.

- What method of cleaning would be suitable for the installation, direct flush to drain, use side stream filters, sand filters, etc?.

- What guidelines should be used to perform the flushing [BSRIA BG 29 etc].

- Are the expectations and requirements for flushing loops at equipment and/or terminal units clearly stated?.

- Is it expected that the new system pumps are used for the works or should the contractor source and supply temporary pumps?

- If are to source temporary pumps, is the size freely available in the market to rent/purchase?. They should note that sometimes it is not feasible to use temporary pumps due to the size of the system and expected flushing velocities.

- If the new system pumps are to be used, once completed the works will there be a requirement for inspecting the internal components of the pumps used to ensure no damage. Will the impellers and gaskets require replacement?.

- Where flushing to drain, will there be a requirement for any licenses?.

- What will be the method of draining the water from the system?. Will the building be connected to the mains drainage system and can use that, or should there be temporary measures put in place such as using tankers, etc to remove any waste?.

- Similar to the draining, what will be the method for filling the system

- Will, there be sufficient power available, will it be expected to be permanent or temporary?

Planning of the works

General Requirements

As noted above the planning of the works should be started at the outset, when the pipework systems are starting to be designed, specified, and drawn out by the design team.

Leading on from the works completed by the designer, the commissioning manager should review during their early-stage commissioning reviews for compliance to the specifications and requirements until the guidelines that are being adopted for the project, which is usually BSRIA in the UK under BG-29.

Onsite Planning

Onsite planning is not one of those things that should be left till just before the works are to start, it should be implemented once the contractors are instructed and ready with their commissioning teams via workshops and meetings.

Discussions would center around flushing methods, strategies, programme/expected time, equipment, resource, sequencing, and coordination works.

If not tackled early enough, the project could discover that the permanent pumps are not allowed to be used and the contractor is to supply temporary ones, with a delivery time of 12 weeks, 2 weeks from when the works are to start.

Pipe Flushing Standards and Guidelines that can be used and referenced

We have not seen many guidelines produced in the United States, if you know of any drop us a note. Within the UK the following can be used as a reference and also specify the project requirement to ensure a standard complete flush and chemical clean is achieved.

Note that the documents for the commercial and industrial systems would generally cover systems over and above 200 liters.

Commercial / Industrial Systems

- BSRIA BG-29 – Pre Commission Cleaning of Pipework Systems.

- BSRIA BG-50 – Water Treatment for Closed Cooling and Heating Systems.

- British Standard BS 8552 – Sampling and monitoring of water from building services closed systems.

Other standards and guidelines for domestic use

- BS 7593 – Code of practice for the preparation, commissioning, and maintenance of domestic central heating and cooling water systems.

- British Standard BS 8554 – Code of practice for the sampling and monitoring of hot and cold water services in buildings.

- PD 855468 – Guide to the flushing and disinfection of services supplying water for domestic use within buildings and their curtilages.

For the next step in the Flushing and Cleaining Process go to our article 'DYNAMIC FLUSHING | Procedure & Sequence' where it provides a step by step outline of a flushing and cleaning procedure

Flushing & Cleaning Document Review Checklist

⬛ Related Articles

BACK FLUSHING | Procedure & Sequence

CORROSION COUPONS | and Coupon Rack

FLUSHING & CLEANING | Pre-Works Check List

FLUSHING & CLEANING | Monitoring after Flushing

DYNAMIC FLUSHING | Procedure & Sequence

CHEMICAL CLEANING FLUSHING | Procedure & Sequence

![Flushing & Chemical Cleaning Method Statement [MS Word]](https://constructandcommission.com/wp-content/uploads/2022/04/000-PH-Document-Graphic-Sell-3.webp)