Made of similar metals and materials to the system components; scaling and or corrosion coupons are installed within a hydraulic system [chilled water/condenser water] to allow the examination of the overall ‘corrosion rate’, allowing the system’s current condition to be understood and the ability to also predict its future life expectancy allowing for preventative maintenance measures.

What is a corrosion coupon

A coupon is a ‘strip’ of metal that is manufactured to precise tolerances focusing upon its weight and dimensions to allow accurate testing after a period of being installed within a system.

Coupons should be manufactured from a metal similar to the system materials, or from a one that is more reactive, similar to zinc or aluminum, to accelerate the corrosive conditions, providing earlier warnings.

They are usually stenciled with numbers which will allow proper identification when being used on-site and recording the testing.

How do they work and how do you test them?

They are installed into a closed or open loop system where they should be electrically isolated to ensure any corrosive effect is only from the fluid within the system.

If using the ‘weight-loss method’, prior to installation, each coupon should be weighed, with an accurate calibrated scale and the information recorded for future reference.

During the time they are installed and the system water is flowing over and around them, they will start to corrode – the recommended installation time for the coupons would be 90 days. This is to allow acclimatization to the system. It has been noticed if only install for a short period of time, under 30 days, the corrosion rate is usually higher.

Once the testing has been completed, they are removed and sent to a laboratory, where they will be cleaned and weighed to understand the rate of corrosion.

All testing and analysis should be completed in line with the following standards:

- ASTM G1 – Standard Practice for Preparing, Cleaning and Evaluating Corrosion Test Specimens.

- ASTM G4-01 – Conducting Corrosion Testing in Field Applications

- ASTM D2688 – Standard Test Method for Corrosivity of Water in the Absense of Heat Transfer

- NACE RP0497 – Field Corrosion Evaluation Using Metallic Test Specimens

As can be seen within the AWT Standard for corrosion rates the classification of corrosion rates for open and closed recirculating cooling water systems are:

Open Pipework System [Condenser]

| Description [Open System] | Carbon Steel [mils-per-year] | Copper Alloy [mils-per-year] |

| Negligible or Excellent | Less than or equal to 1 | Less than or equal to 0.1 |

| Mild or Very Good | 1 to 3 | 0.1 to 0.25 |

| Good | 3 to 5 | 0.25 to 0.35 |

| Moderate to Fair | 5 to 8 | 0.35 to 0.5 |

| Poor | 8 to 10 | 0.5 to 1 |

| Very Poor to Severe | >10 | >1 |

Closed Pipework System [Chilled Water/Heating]

| Description [Closed System] | Carbon Steel [mils-per-year] | Copper Alloy [mils-per-year] |

| Excellent | Less than or equal to 0.2 | Less than or equal to 0.1 |

| Good | 0.2 to 0.5 | 0.1 to 0.25 |

| Moderate | 0.5 to 0.8 | 0.25 to 0.35 |

| Poor | 0.8 to 1 | 0.35 to 0.5 |

| Very Poor to Severe | Greater than or equal to 1 | Greater than or equal to 0.5 |

What are the benefits and disadvantages of using Coupons?

Advantages

- Inexpensive.

- Simple to use, no risk of ‘instrument’ failure.

- Different metals can be tested at the same time.

- Corrosion and bacteria, if required, can be obtained from the surface for further anaysis.

Disadvantages:

- Time to complete the testing.

- Can only provide average readings and won’t be able to show annomolies across a time period.

- Corrosion is not normally constant, the coupons will not be able to show this.

What materials are coupons made from?

The coupon material used for monitoring will depend upon the materials in the system, below is a list of materials that are available:

- Mild Steel

- Copper

- Stainless Steel [303, 304, 316]

- Nickel

- Brass

- Bronze

- Aluminum

- Galvanized Steel

What are the common sizes?

Coupon strips are generally ½ inch (12.5 mm) wide, 3 inch (75 mm) in length, and 1/16 inch (1.6 mm) thick as per the ASTM standards.

How to install coupons?

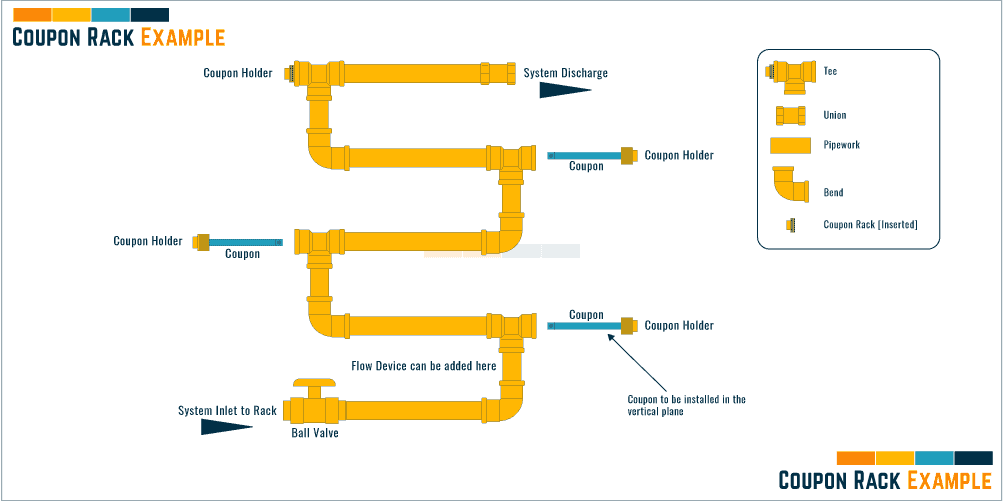

Coupons would usually be installed in a ‘coupon rack’, see below for additional information. Within the rack will be ‘coupon holders’, usually one to six numbers, to allow installation and fixing of the metals being used.

They should be installed so that the flow of the water is from the back of the coupon and that its broad face is in the vertical position, this reduces the risk of accumulation of debris on its face.

The coupon strips should be easily installed and removed when needed.

Galvanic Series

If using multiple types of metals for the installation, the galvanic series should be considered.

The most active metal should be installed in the first position then leading through the metals in the next positions until the last being the most noble of the metals being tested.

For example:

- Aluminum [Least Noble]

- Galvanized Steel

- Mild Steel

- Brass

- Bronze

- Copper

- Nickel

- Stainless Steel [Most Noble]

What is a Corrosion Coupon Rack?

A rack will usually consist of a range of 1″ / 25mm plastic PVC, CPVC, Carbon Steel or Stainless Steel pipework designed to the ASTM requirements, and wall-mountable for easy installation.

The rack should be installed at a distance of between 10 to 30 feet / 3m to 9m from the main system pipework.

A flow of water should pass through the rack from the bottom to the top, reducing any risks of airlocks, and at a flow rate that is between 0.4 m/s to 1.8 m/s. The flow can be controlled by a ‘rotameter’

They can be supplied with isolation valves, and solenoid valves for controlling the water [on/off], a paddlewheel water meter, coupon holders, and a Rotameter

How do you monitor the Coupons

If the coupons are needing to be inspected then they can easily be removed from the ‘Rack’. This is usually achieved by unscrewing the co

upon holder and sliding out. Make sure the system is isolated and do not touch the ‘coupon’ as grease from the hands may interfere with the results.

What are the differences between a Coupon and a Probe?

As noted in this article, a coupon is usually a metal strip that is installed into a ‘rack’ and is manually cleaned, evaluated and weighed after a period of time has passed to understand the corrosion rate within a chilled water/condenser water system.

The installation is quite inexpensive but takes time to obtain any results which only show an average of corrosion, and sometimes the reaction to the problem can be quite a while.

Probes on the other hand are electronic monitoring devices that are installed into the system and are a lot more expensive.

They can provide instantaneous results, allowing trend monitoring to see all peaks and troughs of the corrosion being measured and immediate investigations and remedial actions can be taken.

Some people suggest having both types, the electronic probe for instantaneous detection and remedial actions, and the metal coupon strips for providing a visual picture of the corrosion in the system over a longer period of time.

How do you test and commissioning a Coupon Rack?

There is not much to be done to functionally test a coupon rack, general checks to complete would be:

- Ensure installed inline with manufacturers literature and requirements.

- Ensure coupon strips are of the correct material.

- Coupons are of the correct dimensions and weight.

- Coupons are stamped and numbered.

- Review the flow rate across the coupons to ensure it meets the requirements and that there is no risk of wear happening.

Maintenance of the Coupon Rack

Maintenance is quite simple, each month that the system is in operation, manually check all fasteners and visibly check for leaks and if there is any abnormal wear on the coupons.

If leaks are detected then there could be an issue with the ‘O’ Rings at the joint the leakage is seen [cut, scored, debris, or missing].

If notice abnormal wear on the coupon, this could be due to high flow rates, so check those and reduce where necessary.

⬛ Related Articles

WATER COOLED CHILLER | Pre-Commissioning Checklist

LOW PRESSURE PNEUMATIC TEST | Prior to Hydraulic Testing

CHEMICAL CLEANING FLUSHING | Procedure & Sequence

FLUSHING & CLEANING | Pipework Systems Overview

HYDRAULIC PRESSURE TESTING | Explained with Templates

BACK FLUSHING | Procedure & Sequence