A calibration certificate is a document issued by a calibration laboratory that verifies that a ‘measurement instrument’ or ‘system’ meets specific standards of accuracy and precision, ensuring its measurements are consistent and reliable.

🟩 What does ‘Calibration’ Mean?

Calibration is the process of adjusting and verifying the precision and accuracy of a ‘measurement instrument’ or ‘system’.

It is a quality control process that ensures that a device produces reliable and accurate results by comparing its output to a known standard.

It is essential in various fields, including commissioning systems and services within a construction project, ensuring consistent and reliable measurements.

🟩 What are the Five Benefits of Calibrating Instruments?

There are many important reasons for calibrating our instruments; the five key ones are:

- Accuracy: ensuring the instrument produces accurate measurements essential for reliable results across our projects.

- Precision: ensuring the instrument produces consistent and repeatable results.

- Quality control: ensuring that the instrument produces reliable and accurate results across the project.

- Regulatory/Specification compliance: help meet these requirements, as ‘calibration’ usually forms part of the project commissioning documents.

- Confidence: Calibrated instruments help the project have confidence in the measurements’ accuracy and reliability and allow accurate verification.

🟩 ‘Accuracy’ vs. ‘Precision’

Accuracy and precision are two essential concepts in measurement. They are often used interchangeably, but they refer to different aspects of measurement.

- Accuracy refers to how closely a measurement is to the actual value of what is being measured. A measurement is considered accurate if it is close to the actual value.

- Precision refers to the degree of reproducibility of the measurement. A measurement is considered precise if it is consistent and repeatable.

🟩 What is a Calibration Certificate?

As noted in the introduction, a calibration certificate is a document that verifies and proves, as long as it is in date, that a particular instrument fulfills specific requirements for accuracy and precision and details information on the device and calibration results.

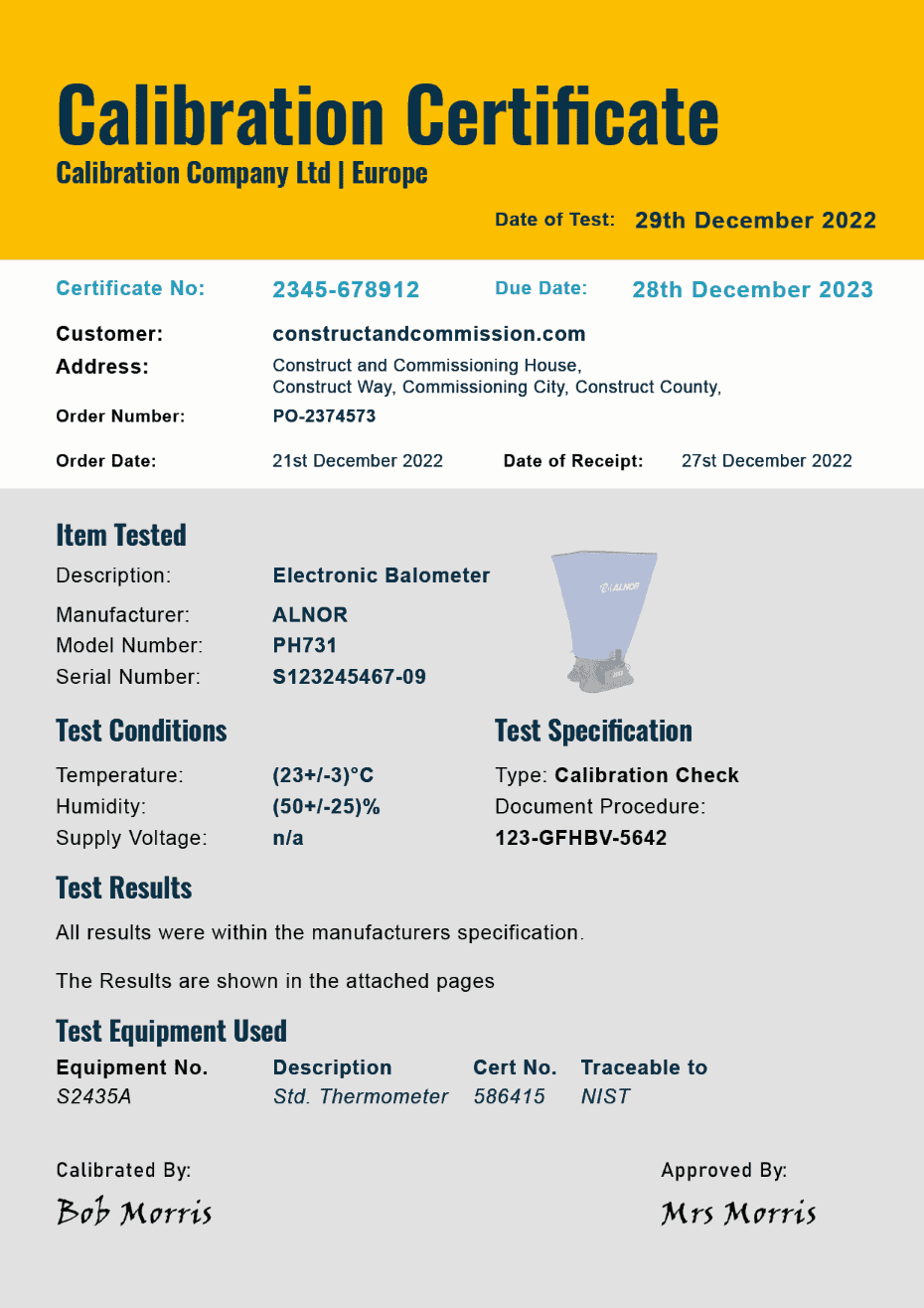

🟧 Information typically included on a calibration certificate

The certificate will include the following information, which can be cross-referenced with the instrument’s information or sticker that is placed on it by the calibration laboratory:

- calibration laboratory information,

- who the instrument belongs to,

- unique certificate number,

- make and model number,

- serial number,

- date instrument calibrated,

- date certificate expires

- the calibration method used and measurements taken, tolerances, and instruments used,

- calibration results.

🟨 Example of a Calibration Certificate

The below provides an example of a typical calibration certificate format and layout

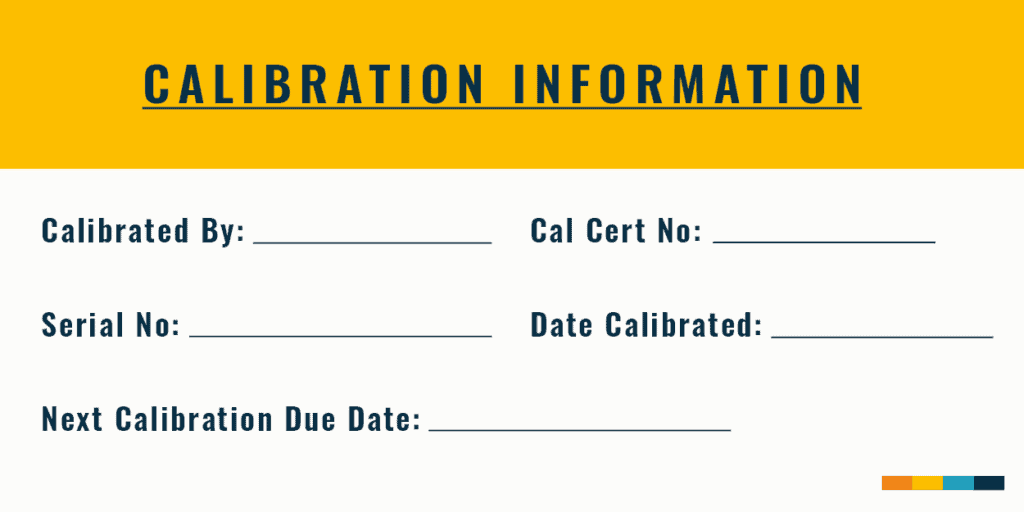

🟨 Calibration Stickers on the Instrument

Calibration stickers are used in conjunction with the certificate; they detail critical information such as:

- calibrated by

- serial number of the instrument

- calibration certificate number

- date calibrated

- the due date for the next calibration

◻️ Example Sticker

Below is an example of a sticker format; many layouts can be used and purchased/created, a selection of labels can be seen at 🔗QClabels.com in the USA or 🔗Calibration Labels in the UK.

The stickers should be easy to write on but hard to rub off, be able to withstand site conditions, and, if removed/replaced, be manufactured so that any tampering would result in damage and or ripping.

🟧 Examples of Equipment requiring a Calibration Certificate

Below is a list of example equipment that could be used during the commissioning process, where a calibration certificate would generally be expected.

| Example Equipment |

|---|

| Accelerometer |

| Anemometer |

| Balometer |

| Calibrated Door Fan |

| Clamp Ammeter |

| Continuity Tester |

| Dial Gauge |

| Duct Pressure Gauge |

| Earth Loop Impedance Tester |

| Earthing and Ground Resistivity Tester |

| Electronic Micromanometer |

| Harmonic Analyzer |

| High Voltage Flash Tester |

| Humidity Sensor [air] |

| Incline Manometer [flow measurement] |

| Infrared Thermometer |

| Insulation Tester |

| Low Resistance Ohmmeter/Ductor Tester |

| Lux Level Meter |

| Multi Tester |

| Oscilloscope |

| IAQ Sampler |

| Phase Rotation Meter |

| Power Analyzer |

| Pressure Gauge |

| Primary Current Injection Tester |

| RCD Tester |

| Refrigerant Pressure Gauge |

| Refrigerant Verification Kit with Calibration Gas and Variable Regulator |

| Secondary Current Injection Tester |

| Sound Meter |

| Tachometer |

| Temperature Sensor [air] |

| Temperature Sensor [water contact] |

| Temperature Sensor [water insertion] |

| Test Fan |

| Thermal Imaging |

| Torque Wrench |

| Ultrasonic Flow Meter |

| Ultrasonic Weld Testing Equipment |

| Vacuum Gauge |

| Voltmeter |

| Water Flow Meter |

| Water Manometer |

| Water Quality Sampling Kit |

🟩 Standards Used when Calibrating

The Calibration Laboratories calibrating our equipment and instruments follow National/International Standards that specify the measurement requirements ensuring that they are accurate, consistently measured, follow a strict procedure, and is using a reference instrument that is appropriate for the job and itself calibrated.

The following standards are the most common we come across in the

- ANS/ISO/IEC 17025: An International Standard sets out the requirements that a laboratory can follow to demonstrate that they are competent, impartial, and produce accurate, consistent results. 🔗ISO/IEC 17025

- ISO 10012: This International Standard promotes the management systems for management systems that stipulate the requirements for the selection, use, and maintenance of measuring equipment. 🔗ISO 10012

- ISO 9000: This is a set of standards used for controlling Quality Management Systems, including the most common ISO 9001. 🔗ISO 9000

🟩 Steps to Obtain a Calibration Certificate

It’s not that complex to obtain a calibration certificate for an instrument, but a few steps should be followed:

🟧 Step 1 – Understand the Equipment to be Calibrated

Evaluate the equipment and instruments that are to be used during the commissioning process and review their existing ‘due dates’.

Note the equipment that is out of calibration and requires a new certificate.

🟧 Step 2 – Locate a Laboratory to Calibrate the Equipment

Locate a company/laboratory that can calibrate the instruments in line with the relevant international standards.

If your company does not have a regular laboratory, they can be located on Google pretty quickly.

🟧 Step 3 – Aquire Costs & Send Order

Speak with the laboratory and request costs for the works; once confirmed and agreed, issue an order.

🟧 Step 4 – Dispatch Instruments to Laboratory

Dispatch the instruments to the laboratory. Ensure they are secure as they can be ‘fragile’.

🟧 Step 5 – Laboratory Calibrate Equipment & Certificate

The laboratory will calibrate the equipment in line with the required International Standards and issue the relevant Calibration Certificate.

🟧 Step 6 – Laboratory Dispatches Instruments

Once the works are complete, the laboratory will dispatch the instruments with the required calibration certificates back to the project/client.

🟧 Step 7 – File and Log Certificates

Once the instruments and certificates have been received, they should be safely stored, with the certificates being logged/scanned and scanned for future reference or presentation.

🟩 What are the Expected Calibrating Intervals

Incorrectly, many of us think that we should calibrate our instruments at set intervals, usually every 12 months, due to most certificates or stickers having a ‘due date’ – 12 months from the date of calibration.

In general, equipment such as pressure gauges, temperature sensors, flow meters, electrical meters, and multimeters would be calibrated at regular intervals to ensure that they measure accurately and reliably when used on-site. The recommended calibration interval can range from every few months to a few years, depending on the specific device, its intended use, and other factors such as:

- manufacturers literature

- last calibration date

- condition of the instrument/equipment

- previous handling of the instrument/equipment

So as we can see, there is no strict requirement; the Engineer should be confident that the instruments and equipment used to take any measurements during the commissioning works are fit for purpose.

If there is any concern that they are not, they should request they be re-calibrated.

⬜ Equipment Calibration Log Template

![Equipment Calibration Log Template [Excel]](https://constructandcommission.com/wp-content/uploads/2022/12/119-Calibration-Equipment-Log-Page.png)

⬛ Related Articles

TRAINING MANUAL | for Operational Staff at Handover with Template

COMMISSIONING REPORTS | Templates Weekly, Monthly, Daily, Final Report

PREQUALIFICATION OF TENDERERS | How to Conduct, Manage & Complete

LEED FUNDAMENTAL COMMISSIONING | Steps and Downloads

[RFI] REQUEST FOR INFORMATION | What is it in Construction with Templates

PUNCH LIST | Explained with Template